However, the ideal would be to have an ink suitable for all kinds of textile substrates. This request is to be fulfilled by the use of pigment inks. In this article, Zschimmer & Schwarz will describe the role of pigment inks for digital textile printing – do they have a real chance in the future or is it just a hype?

Pigment inks: Characteristics, application, and market

Rather than a dye that is soluble, water-based pigment inks use an insoluble pigment to provide coloration of the textile. Compared to dyes, the pigments do not have a real affinity for special fibres, which makes them suitable for colouring on the top layer of a various number of fibres as well as blends.

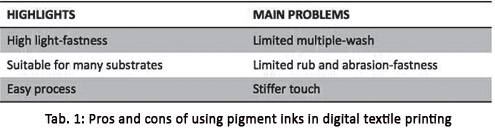

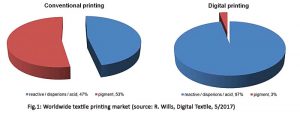

However, the global textile printing market (Fig.1) shows that pigment inks represent only about 3 per cent of inks used in digital textile printing. Inks most commonly used are still based on reactive, disperse and acid dyes. There are different reasons for the currentlow market share of pigment of pigment inks in digital textile printing. As previously mentioned, due to the top layer of printing by using a binder for better substrate adhesion, most pigment inks are limited when it comes to multiple-wash as well as rubfastness. Furthermore, the feel of the fabric is often stiffer than in reactive printing which is one of the main problems, especially in fashion or bed linen for example.

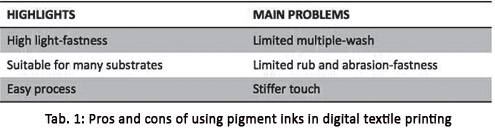

On the other hand, the use of pigment inks shows some remarkable benefits (Tab. 1). With the suitability of printing on a various number of textile substrates a broad field of application can be served, ranging from home textiles, soft signage and banners to fashion (mainly T-shirts) or speciality products. Pigments are especially beneficial in areas where high light-fastness is required. Furthermore, the entire process, compared to reactive prints, is very quick and easy.

Pigment versus reactive printing

Pigment versus reactive printing

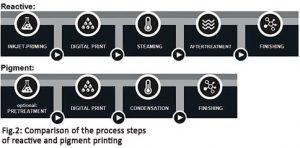

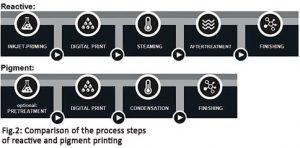

As mentioned above, one benefit of using pigment inks in digital textile printing is the ease and length of the process. Fig. 2 schematically shows the process of printing with pigment inks compared to reactive inks. Due to their chemical characteristics, reactive dyes have to be bonded to the textile fibre after printing. Therefore, a steaming process of 8-12 minutes at 102°C (saturated steam) is necessary. Subsequently, the unbound dye has to be removed in a complex washing process (after treatment) at different temperatures ranging from about 50°C to 98°C, with soaping agent to 60°C, and finally 30°C (slightly acid). Then the printed textile has to be dried.

In comparison, the pigment printing process does not need the complex steaming and washing steps. Since the pigment dye is printed only on the top layer of the fabric without any chemical bonding, the textile fabric has to be condensed at 150-170°C for a few minutes to fix the pigments. Consequently, the pigment printing process requires significantly less water due to the omitted washing step. This may be a crucial deciding factor when deciding on whether to use digital pigment printing in the future.

In comparison, the pigment printing process does not need the complex steaming and washing steps. Since the pigment dye is printed only on the top layer of the fabric without any chemical bonding, the textile fabric has to be condensed at 150-170°C for a few minutes to fix the pigments. Consequently, the pigment printing process requires significantly less water due to the omitted washing step. This may be a crucial deciding factor when deciding on whether to use digital pigment printing in the future.

Nevertheless, an additional point has to be mentioned regarding the printing process with pigment inks. Due to the insolubility of the pigment particles, the sedimentation of them could result in problems of nozzle clogging in the fine nozzles of inkjet printing machines.Therefore, to overcome this, two things should be noted: Firstly, all the inks have to be well stirred before using and secondly, the necessity of a print head with a circulating system becomes more and more important. The circulation provides a kind of continuous flow that avoids sedimentation and thus clogging the nozzles. In particular, the white pigment inks mostly based on the inorganic compound titanium dioxide need those circulating systems.

Nevertheless, an additional point has to be mentioned regarding the printing process with pigment inks. Due to the insolubility of the pigment particles, the sedimentation of them could result in problems of nozzle clogging in the fine nozzles of inkjet printing machines.Therefore, to overcome this, two things should be noted: Firstly, all the inks have to be well stirred before using and secondly, the necessity of a print head with a circulating system becomes more and more important. The circulation provides a kind of continuous flow that avoids sedimentation and thus clogging the nozzles. In particular, the white pigment inks mostly based on the inorganic compound titanium dioxide need those circulating systems.

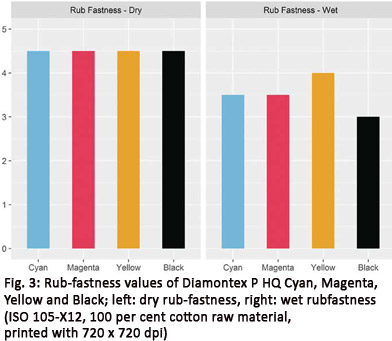

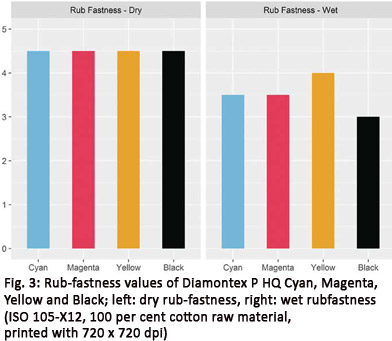

Inks exhibit a reliable printing performance, an easy handling, and cleaning, an outstanding light-fastness and can be processed according to the easy process described earlier. Furthermore, due to their chemical characteristics, it is possible to achieve very good rub-fastness values with these inks (Fig. 3, exemplified for cotton raw material). The dry rub-fastness values are in a range of 4-5 and the wet rub-fastness in a range of 3-4.

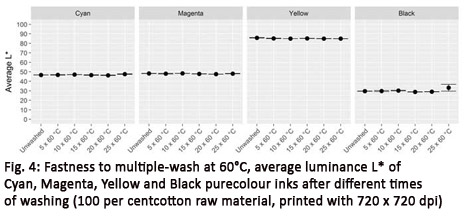

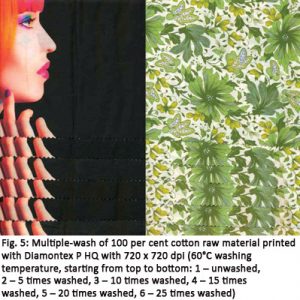

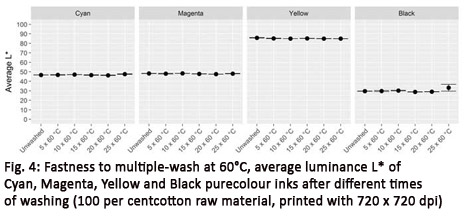

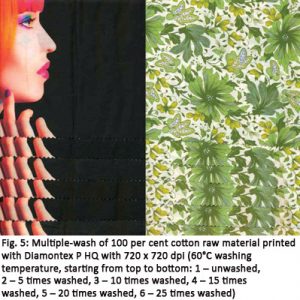

Additionally, investigations looking into multiple-wash have been done for cotton raw material by washing the printed and fixed textiles at 60°C for several times up to 25 times. Figures 4 and 5 illustrate the outstanding performance of Diamontex P HQ inks in case of multiple-wash. Any significant changes in the colour yield of the print could not be observed after up to 20 times of washing at 60°C. The average luminance is nearly stable in all basic colours. This colour stability is the basis for coloured printed motifs over several washes which can be seen in Figure 5.

Additionally, investigations looking into multiple-wash have been done for cotton raw material by washing the printed and fixed textiles at 60°C for several times up to 25 times. Figures 4 and 5 illustrate the outstanding performance of Diamontex P HQ inks in case of multiple-wash. Any significant changes in the colour yield of the print could not be observed after up to 20 times of washing at 60°C. The average luminance is nearly stable in all basic colours. This colour stability is the basis for coloured printed motifs over several washes which can be seen in Figure 5.

Outlook

Pigment inks have the potential to have a big future in digital textile printing, especially when it comes to environmental aspects and process simplification.As well as being used on commonly used textile materials such as cotton, polyester, and polyamide, pigmented inks can also be used to easily print on mixed fabrics such as cotton-polyester blends where two different ink types are usually necessary. Moreover, the usage of Diamontex pigment inks opens up the possibility to print on specialised materials. Some tests have already been done on textile substrates that are usually difficult or almost impossible to digitally print on and these tests have had promising results.

Pigment inks have the potential to have a big future in digital textile printing, especially when it comes to environmental aspects and process simplification.As well as being used on commonly used textile materials such as cotton, polyester, and polyamide, pigmented inks can also be used to easily print on mixed fabrics such as cotton-polyester blends where two different ink types are usually necessary. Moreover, the usage of Diamontex pigment inks opens up the possibility to print on specialised materials. Some tests have already been done on textile substrates that are usually difficult or almost impossible to digitally print on and these tests have had promising results.

Finally, pigment inks for digital textile printing have a great chance to prevail in the market for special material applications but also for the commonly used textile fibres when needing to save energy and water consumption.

By Andreas Schönfeld, Dr. Julia Ahrens, Dr. Nora

Wetzold, Peter Oehme, Oliver Richter from

Zschimmer & Schwarz digital printing team

Since the mid-90s, research on digital textile printing has become more and more important. This application field offers the possibility of printing photographic-quality images with quick design time. A great advantage, especially for the fashion industry, is the ability to print-on-demand in small quantities down to a lot size of one. According to an analysis by the WTiN Intelligence: Digital Textiles, the worldwide output of digitally printed textiles is growing at an annual rate of approximately 20 per cent. Despite this rapid growth, the proportion of textile production that uses digital printing is only about 3-5 per cent up to now. One difficult criterion for effective industrial digital printing on textiles is the various number of different textile substrates ranging from natural such as cotton, wool or silk to synthetic materials like polyester and blended fabrics. All these fabric types require different types of inks and additional different needs for pre and post-treatment as well as processing. The ink types mainly used in industrial applications are reactive inks for natural fibres and sublimation/disperse inks for digital printing on polyester.

Since the mid-90s, research on digital textile printing has become more and more important. This application field offers the possibility of printing photographic-quality images with quick design time. A great advantage, especially for the fashion industry, is the ability to print-on-demand in small quantities down to a lot size of one. According to an analysis by the WTiN Intelligence: Digital Textiles, the worldwide output of digitally printed textiles is growing at an annual rate of approximately 20 per cent. Despite this rapid growth, the proportion of textile production that uses digital printing is only about 3-5 per cent up to now. One difficult criterion for effective industrial digital printing on textiles is the various number of different textile substrates ranging from natural such as cotton, wool or silk to synthetic materials like polyester and blended fabrics. All these fabric types require different types of inks and additional different needs for pre and post-treatment as well as processing. The ink types mainly used in industrial applications are reactive inks for natural fibres and sublimation/disperse inks for digital printing on polyester.