Morgan is a group of companies, based in Adro (Brescia), Italy. Morgan Tecnica Spa and Morgan Dynamics are responsible for the design, creation and manufacturing of machinery/software/products used to automate the cutting rooms of many industries around the globe. It has automated processes in all areas of the cutting room from fabric loading, automatic/intuitive spreading, label printing and state of-the-art cutting machines, all being linked together with our single and multi-level tables.

Next 70 (TAGLIO – Cutter)

The ‘’next’’ generation of electronics is already ‘’present’’ in the new range of automatic cutters Morgan ‘’Next’’, now faster and more precise. Discover the incredible savings of the ‘’Zero Buffer’’ cut technology.

Add more flexibility to your job

Is the most flexible machine of the entire range. It has extremely low power consumption and it is fully digitally controlled, with an amazing ‘’made in Italy’’ design. The vacuum controlled by digital inverter allows to drastically reduce the power consumption as well as the best flexibility in cutting any thickness of lay, from single ply to 7 cm compressed, with any kind of materials, from the elastic to the very hard one.

Morgan Next 70 delivers the highest performances in terms of productivity, quality and reliability, together with one of the lowest maintenance costs in the market. Digital active control of the blade bending in real time allows best cutting precision even on high thickness lays and hardest material. Available in version standard 4,500 rpm or HM 6000 rpm specific for hard and difficult materials.

Software Apps

- Innovative graphics interface (icon touch), modern and user-friendly

- Zero Buffer Cutting

- Automatic detection of symmetric patterns and cutting direction management

- Common Lines Management

- Pattern Proximity Detection and dynamic speed control

- Perimeter harmonization by automatic fixing of digitalization errors

- Best start point automatic calculation for each pattern

- Best cutting window automatic calculation

- Smart cut sequence – to minimise empty movements and improve cutting quality

- Special automatic functions for the waist band (specific for denim)

- Active notch management – dynamic notch type changing

- Notch conversation (on fly, ‘’V’’ notches, castle notches)

- Markers batch list elaboration

- Markers joining

- Detailed statistics & graphic reports

- Compatible with Morgan Analytics integration

Hardware Characteristics

- Interactive multi – touch computer on board • Auto – diagnosis system

- Dynamic Vacuum system, managed by digital inverter • Automatic loading/unloading conveyor system • Power consumption optimization system

- Digital brushless motors • Sharpening belts device • Noiseless

• Washable and easy removable vacuum filter • Latest generation of Omron electronic devices • Blade bending active control • Long life bristles

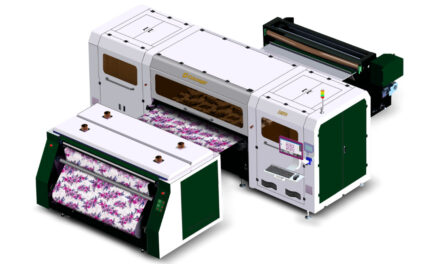

Essentials Matching System by Morgan

Essentials Matching system consists of pin Table, Visual pingrid software, pingrid visual Accessories and fabric feeder (optional). The pin table for spreading stripe and plaid fabrics available in module of 4,6 and 8 mtr, structure in oven varnished metal, with 5×5 cm hole on the table top for needle positioning based on matching rules. Motorized needle height adjustment helps for easy and accurate pinning operation.

Visual accessories are a windows PC along with industrial short through projector, wireless keyboard and mouse Visual Pingrid Nest software is the most practical and effective system for viewing and editing markers in real time, directly on the spreading table.

Visual Nest – Save your time & cost

Designed to help the manual spreading of striped or checked fabrics on the needle table, using the projection of the grid of the theoretical repletion ratios, useful for operators to guide the alignment and holding of the fabric, Visual Nest proved itself suitable for multiple other useful applications, both in the manual spreading of patterned fabrics or prints, in the spreading of continuous, fabric to verify the location of defects, in the overlaps management, in the control of compliance with minimum width and length of the layer, during the spreading, etc…

Fabric Feeder is an optional device assist to feed the fabric for pinning operation for easy and fast pinning operation, possible to feed roll from and relaxed from fabrics with easy switch over, especially for knitted fabrics the fabric can be fed with less stretching. Runs on rails of the pinning table very smooth and easy to move by operator.

Technical Specifications and features

- Projection area for each projector of 3.5 by 2 m

- Possibility to control multiple projectors simultaneously

- Possibility to modify the repetition and to move each individual line, in case of irregular repetition

- Possibility to modify the repetition angle, to adapt to off grain fabric

- Possibility to move each individual piece of the marker by mouse, for proper matching

- Possibility to rotate each individual piece of the marker by mouse to follow off grain fabric

- Possibility to customize the colour combination to easily adapt to any type of fabric

- Compatible with ISO