Even as the Indian cotton yarn sector is struggling to hold its head above water, comes the alarming news—creation of new spinning units at the cost of existing ones. Reports have it that new units have sprung up in Andhra Pradesh and Telengana, among others, with patronage from the respective State Governments. The Centre has no role in this. Rather it is against giving incentives for the new units.

On the external front– and that is very crucial—is the gradual emergence of Vietnam as major competitor to India. Vietnam has attracted sizeable Chinese investment in its spinning segment. What is more, China buys back yarn produced in Vietnamese factories. And no customs duty is levied by China on the yarn supplies.

It is not therefore surprising that Vietnam’s share of cotton in the Chinese market has been rising fast over the years. Vietnam’s exports have increased by a whopping 88 per cent between 2013 and 2016. India’s exports, on the other hand, have plummets by as much as 49 per cent in this period—from $2,175 mn to $1,102 mn, as per the latest data.

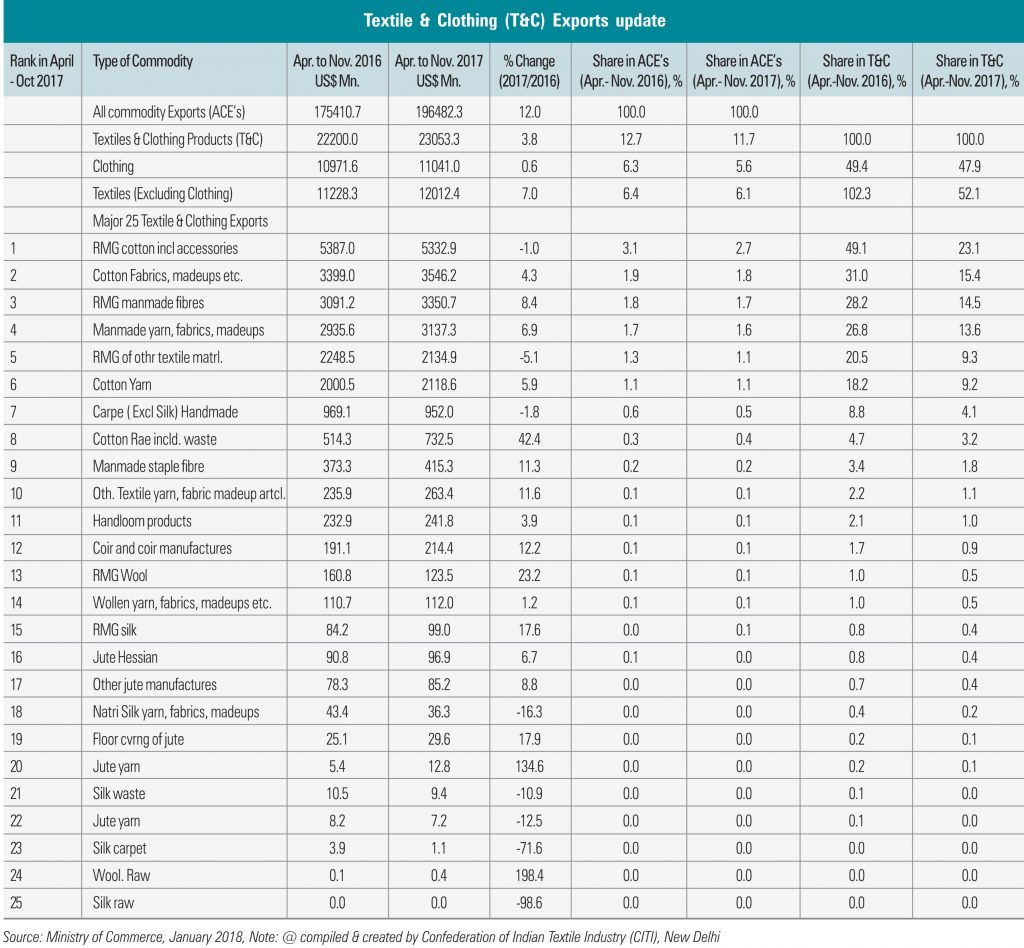

Again, data furnished by the Textile Commissioner’s office in Mumbai shows that the total cotton yarn exports have fallen from $4,584 mn in 2013-14 to $3,962 mn in 2014-15 to $3,621 mn in 2015-16 and to $3,369 mn in 2016-17. In the first quarter of 2017- 18 (April-June), these exports have declined by 7.95 per cent, indicating a continuous fall. During the same period, Chinese imports of yarn from India have shown a decrease of 45 per cent – from $1,918 mn to $1,053 mn. This period also saw an increase in Chinese yarn imports from Indonesia by 24 per cent and Uzbekistan by 42 per cent, as per the data available with UN Comtrade.

There also exists an unfavourable duty structure. Bangladesh and Pakistan levy higher rates of duty on Indian yarn while they enjoy duty-free access or concessional duty access in India. Pakistan has increased customs duty on yarn from 5 to 10 per cent recently. China, too, has slapped a 3.5 per cent duty on Indian yarn.

Another reason why India is losing out on exports is exports of taxes as all taxes are not being refunded to exporters. The embedded State level taxes/levies which remain unadjusted account for about 7-8 per cent of the export price of yarn. Our competing countries however enjoy full tax refund and even Vietnam and Bangladesh have preferential to many large markets, putting India at a double disadvantage. India may continue to lose if a level playing field is not maintained.

The Merchandise India Export Scheme (MEIS), introduced by the government is crucial for the cotton yarn industry. It helps sell surplus cotton yarn production at competitive prices, compensating the impact created by raw cotton cost and decrease in imports by China. Therefore, the two per cent incentive under MEIS should be restored. The advantage of two per cent Incremental Export Incentive (IES) and Focus Market Scheme had helped the industry penetrate into alternate markets other than China (South America, CIS countries Far East countries etc.). The advantage provided by the export incentives helped in compensating the high transport cost involved in exports to such countries. These incentives were withdrawn in 2014 due to some inexplicable reasons. Now, there is a dire need for the government to extend the Interest Equalisation Scheme (IES) to the spinning sector in order to compete effectively in the global market. Moreover, the interest rates in India are higher at 12 to 14 per cent than international ones, ruling at about 2 to per cent. This forces the Indian mills to maintain high inventory stock as China and Bangladesh buy yarn for 90-120 days L/C. The high amount of inventory requires higher working capital which needs to be financed by working capital loan.

Spinning is a capital-intensive industry and is very important for the value added sector to develop and thrive. Currently, the country has 52.45 mn spindles and 8.76 lakh rotors spinning capacity. There is a 30 per cent excess capacity of cotton yarn for exports and the low demand in the global market has forced a large number of mills to cutback on production.

There was a limited growth in the spinning sector in the last five-seven years compared to the preceding five years owing to reduced demand and yarn exports during the last three years. During 2007-12, the addition to the non-SSI spinning sector was 7.70 mn spindles while it was only 3.81 mn spindles in the last five years. India has the second largest spinning manufacturing infrastructure with 52.47 mn spindles and 8.70 lakh rotors.

The cotton textile and apparel sector plays a very pivotal role in the Indian economy. It provides sustainable livelihood to a sizeable population in the country. Cotton is harvested in about 10.5 mn hectares which accounts for 43 per cent of the global cotton area and contributes to 25 per cent of the global cotton production. It is estimated that about 40-50 mn people are employed directly or indirectly by the cotton industry.

Cotton production has declined from 386 lakh bales in 2016-17, registering a compounded annual growth rate (CAGR) of minus 5 per cent. The area under cotton cultivation decreased at a CAGR of 10 per cent during the same period. Exports and mill use has also declined at a CAGR of 7 per cent and one per cent respectively.

Needless to say, the textile manufacturing and trade is still under stress owing to the ongoing transition in the domestic economic environment. As per the RBI Financial Stability Report, the textile sector is amongst the top 3 stressed industries in the economy. Many old mills have been shut down while new capacities are coming up at the cost of the tax payer’s money.

The textile industry has the capacity to produce a wide variety of products suited to different market segments, both at home and abroad. The industry is currently estimated at $259 bn by 2020. But for addressing global competitiveness, quality and productivity improvement, innovation and technology upgradation are of utmost importance. Also, the sector needs to be made attractive enough for investors to speed up its investment.