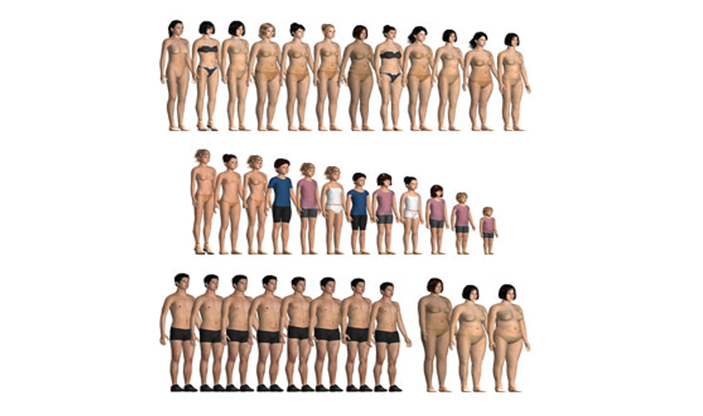

As the necessity for new technologies and processes becomes increasingly more apparent in the apparel industry, multitudes of designers and manufacturers of all sizes are turning to 3D solutions to increase efficiency in product development and enable effective global communication.

For many, the quest for resource-saving technology is often impeded with an ironic, but harsh reality: The initial start-up cost is just too expensive. To combat this deterrent, Tukatech Inc., USA, a global leader in fashion technology solutions (2D/3D CAD/CAM) for the garment and apparel industry, has launched the Enterprise Edition of its TUKA3D system for virtual product development for Indian Enterprises & Fashion Designers. This edition includes all the high-functioning 3D development capabilities at a more attainable price.

Ram Sareen, Tukatech’s Founder and CEO explained, “We know there are companies who want to adopt 3D technologies that just don’t have the capital. I’ve always believed that companies of all sizes should have the same access to advanced technology. We’ve seen the industry in California transformed by the affordability and availability of TUKAcad [for digital pattern-making, grading, and marker-making], 80 per cent of the California apparel industry uses TUKA systems. We hope to see a similar phenomenon in India with the onset of a more economical edition of TUKA3D.”

“We have dozens of vendors, brands, and retailers worldwide reporting amazing results with the implementation of TUKA3D in their product development process. “Going virtual” has allowed one vendor to reduce product development time from 90 days to only 7 days. Another has increased their first-sample acceptance rate from about 93 per cent to 99.8 per cent. So many companies have the innovative spirit and desire to achieve results like this. I can only imagine what will happen in the apparel industry globally with more attainable 3D product development and collaboration technology,” Sareen said.

Not only does TUKA3D EE provide an exceptional 3D product development solution with the TUKA3D software, but users can also take advantage of TUKAcloud, the web-based sample room for digital collaboration. This solution serves as a database of virtual samples, and is also a communication platform that enables product development to take place in a digital environment reminiscent of the traditional design process.

Without getting faster design and approval, we simply could not be in the fashion business. Designers are looking at uploaded samples at their convenience anywhere using mobile or other devices. They can see the 3d sample; zoom, pan, rotate the sample, just like they will in real life on a real person.

In addition there is a video showing how garment and fabric drapes, in tension and X-RAY mode enabling the viewer to see if there are any fit issues. All the colorways, print and embroidery placement can also be viewed. Upon analyzing the 3D sample and the video they can make comments, and the system automatically informs the pattern maker who can see and read the comments, make the required corrections and send the new sample almost immediately.

The system informs the individuals or the designated group to view and approve the final garment. Once the garment is approved for production, it now goes in the Asset Library so designers can use it for future development.

“We make over six million garments per month in hundreds of styles, the only way we can grow our business is to have more developments in a shorter time period with fewer people. This is what Tukatech has done with their solutions installed at all our facilities worldwide,” says Ranju Mahtani, CEO of the Hong Kong based THE EPIC GROUP.

“Today, there are many eCommerce retailers using TUKA3D for designing, developing, and uploading their realistic looking digital assets. They do not require a photo shoot, inventory, or warehousing; the best part is no markdowns. This is “Demand Manufacturing. This is the best way to be profitable and be ahead of everyone else. We are proud to be labeled as the “Disruptive Technologist” and want our customers to be number one,” says Ram Sareen.

There are companies who want to adopt 3D technologies that just don’t have the capital. I’ve always believed that companies of all sizes should have the same access to advanced technology. We’ve seen the industry in California transformed by the affordability and availability of TUKAcad [for digital pattern-making, grading, and marker-making], 80 per cent of the California apparel industry uses TUKA systems. We hope to see a similar phenomenon in India with the onset of a more economical edition of TUKA3D.