Macpi, founded in 1961, is a worldwide leader in manufacturing highly technological machines for garment industry following the tradition of Made in Italy with a constant research in terms of quality, style and innovation that cannot make compromises with a downward policy. The accrued experience of almost 60 years brought Macpi to produce greatly sophisticated automatic units for thermo- fusing, loading and unloading system, complete line for the intermediate and final finishing of jackets, coats, jeans, knitwear, trousers, shirts, automatic machines for stitch-free applications and special units for industrial laundries.

About The Author

Related Posts

Cover Story

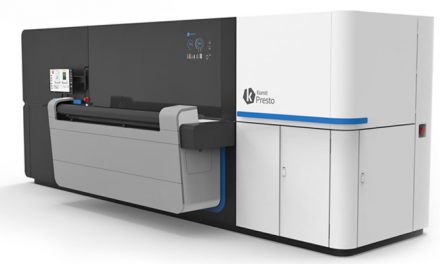

New Aura T-Shirt Printer

Archives

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- April 2021

- March 2021

- February 2021

- January 2021

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- June 2017

- April 2017

- February 2017

534 – Tunnel Finisher

534 – Tunnel Finisher 320.00 – Finishing of Trousers without pleats

320.00 – Finishing of Trousers without pleats