Being an enduring classic, the timelessness of denim can never fade away. Reaching to a level where it has become more than just a trend, denim has carved a distinctive niche in the well-knit tapestry of the fashion world. From being a staple in every fashionholic’s wardrobe to becoming the most deeply loved garment by designers, it continues to be a quintessential masterpiece. Marked with unique cultural connotations, the wear and tear, ageing, perforating, embroidery and more have allowed denim to gradually evolve to emerge as a cult favourite.

Being an enduring classic, the timelessness of denim can never fade away. Reaching to a level where it has become more than just a trend, denim has carved a distinctive niche in the well-knit tapestry of the fashion world. From being a staple in every fashionholic’s wardrobe to becoming the most deeply loved garment by designers, it continues to be a quintessential masterpiece. Marked with unique cultural connotations, the wear and tear, ageing, perforating, embroidery and more have allowed denim to gradually evolve to emerge as a cult favourite.

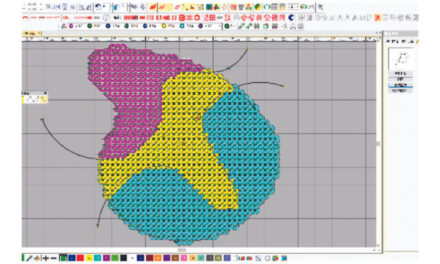

Adding a whole new level of innovation, precision and creativity to the craft of denim manufacturing, laser engraving has emerged as the pinnacle of finesse and flexibility. Since denim is one of the most used fabrics in the fashion landscape, the introduction of lasers in the fabric manufacturing process is poised to have a paramount effect. Leaving behind the long legacy of conventional manufacturing methods, Laser Engraving is the gateway to highly efficient and flexible denim processing, allowing fashionistas to indulge in the serenity of ‘denim customization’.

Creative Fusion of Denims and Laser Engraving

Laser Technology has been a pivotal element of the apparel manufacturing process. Considering the high demand and luxuriousness of the fabric, the innovative tactic of laser engraving is all set to transform the schematics of denim manufacturing. Denim’s versatility is actively being reimagined under the beam of cutting-edge laser technology, with laser engraving opening up a realm of possibilities for designers, brands, and artists seeking to infuse a creative ethos backed by new-age tech into their projects.

Quality-centric Intricate and Consistent Designs

To make its mark on the fashion runways, laser engraving is rooted in delivering unparalleled quality. In situations where maintaining consistent design and pattern proves challenging, laser engraving guarantees quality. Subsequently, it unlocks a new ray of intricate designs in denim manufacturing while allowing brands and designers to play around with detailed designs and etch artworks on clothes like an art canvas.

Eco-Friendly all the Way

Laser Engraving has created an indelible mark on the fashion industry with its unparalleled precision. Its sustainability potential is transforming it into an indispensable asset. Amid the ongoing sustainable fashion waves, the use of laser engraving allows manufacturers to considerably reduce the consumption of water, and chemicals. From this point of view, laser engraving is not only contributing towards carbon footprint reduction, but is also showcasing and encouraging fabric manufacturers to embrace a more ecologically-safe type of production.

Quick TAT translates to Expedited Production

With a fully-automated production process that is standardized and checks down to the smallest detail, laser engraving delivers the possibility of experimentation and also makes way for low MOQ and TAT, which automatically ramps up the production process. This efficiency has opened avenues for maintaining consistent and efficient results across multiple pieces, which has further allowed brands to cater to high demands, driven by a top-notch, and expedited mass production process. This streamlined approach not only accelerates production but also helps brands experiment with various designs among their customers quickly, providing valuable insights into high-selling products and designs.

Beacon of Labour-Effectiveness

Within the realms of conventional fabric manufacturing methods, which were predominantly manual, and labour-intensive, there was no space for prioritising employee-centricity. However, the advent of laser engraving has significantly changed the working perspectives, with an automated process that allows to cut down on TAT, and saves manual hours. As a result, manufacturers get the opportunity to capitalise their focus on other critical tasks. At the same time, it increases productivity, creating an overall working spirit of positivity and dedication.

Budget-Conscious Alternative

Although, the initial capex is high nut in the long-run laser engraving proves to be cheaper than traditional methods. First and foremost, manual methods are attributed with errors and misalignments, which results in increased cost-damage, along with slowing down the production cycle. On the contrary, laser engraving not only reduces the possibilities of errors but being free from any limitations in terms of thickness of material, it allows for faster production which culminates into lower operational costs.

Final Thoughts

From high-street fashion to haute-couture, laser engraving presents a remarkable way for brands to not only make a statement in terms of innovative and personalised designs, but also unlock expedited production. Behind the curtains of intricate designs and fabrics, Laser Engraving offers a holistic production experience, from sustainability, quality, consistency, versatility to labour-effectiveness. As the fashion world traverses further, the power of Laser Engraving within the denim manufacturing space is only going to amplify more.