Apparel manufacturers are using a wide range of creative and ingenious decorative techniques to add value to their fabrics and garments today. The development of these new decorative techniques has been facilitated partly by recent innovations in garment technology. As a result, the range of economical design options for designers and manufacturers has been widened. These innovations have centred on machinery for direct to garment digital printing, embroidery, conventional sewing, embellishment attachment, heat transfer and laser decoration. Additionally, interesting advancements in electronic textiles have taken garment decoration beyond the field of aesthetics by enhancing the functionality of garments for their wearers. This report discusses recent developments in technologies for garment and textiles.

Latest CAD/CAM solutions by Tukatech

Tukatech Inc., a Los Angeles, California based company is a leading solutions provider to the apparel, furniture and automotive industry. Founded in 1995 as PST, Inc; the corporate name was changed to Tukatech in 1997. Tukatech’s advanced software and hardware gives designers, manufacturers and distributors the tools needed to streamline operations, increase efficiency, and expand profits.

TUKAcad 2017

TUKAcad 2017 comes with advanced features for pattern making, grading and marker making, with the effort to automate the pattern making process and minimise human intervention as much as possible. The software is intuitively designed and extremely user-friendly, there is even audio and video help built-in to every tool, available in 14 different languages. There is also a library of graded basic blocks for men, women, and children. The users can work from these to create new styles, or create styles completely from scratch.

TUKA3D

TUKA3D is the fashion industry’s most advanced, easyto- use 3D apparel design and development software. The user can customize virtual fit model, build life-like virtual clothing samples, and create presentations for buyers, retailers, or end customers. Tukatech’s 3D apparel design software eliminates the need for trial and error in physical sample creation, ensuring that any design fits right the first time.

Seamless integration between Tukatech systems enables the user to easily import any 2D pattern from TUKAdesign and prints from TUKAstudio into TUKA 3D. The 2D patterns are electronically sewn and draped onto a 3D virtual fit model to verify look and fit, just as it is done in a traditional fit session. Custom animation gives the user ability to check the fit and behaviour of the garment while the model is in motion.

TUKAcloud

TUKAcloud is designed to combine modern technology with traditional practices. As one central location for all information for every style, TUKAcloud services as a platform that connects brands with their vendors, at any time in any location. The TUKAcloud solution is web-based, so there is no software required to access the entire library of samples. With password protection for every profile, only the relevant people are involved, allowing the sample making and approval process to regain the streamlined expertise it once had. With its “best of both worlds” approach, globalization is less “global” and more collaborative.

TUKAcutplan

TUKAcutplan – MRP is the Material Requirement Planning System integrated with SMARTMARK queue or NET-Q, every possible cost factor and restriction is considered to find the most optimum solution like cost of fabric, marker making cost, spreading cost per yard, cutting cost per perimeter inch, maximum bundles in one layer, length of spreading tables to make sure no marker is made longer than the tables, minimum and maximum layers or plies we can cut. It even considers the end loss on each side.

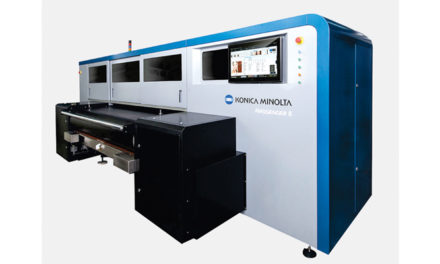

TUKAjet

TUKAjet delivers high speed inkjet plotters in multiple widths. There are options for cutter plotters as well. The plotting capacity is consistent regardless of the amount of annotation. This feature allows the Pattern Maker to give Cutters matching instructions and Marker Makers to label the pattern pieces and markers with appropriate information without any concern of loss in plotting productivity. The Plotters are superbly designed to allow in-house maintenance with very little training. With fewer movable parts, they offer an outstanding reliability.

YIN JAPAN presents latest cutting and spreading technologies

Yin Japan Co, Ltd. manufactures automated cutting machines. It manufactures CAD and CAM products. The company was founded in 2006 and is based in Osaka,Japan. The company operates as a subsidiary of Shanghai Yin Science & Technology Co., Ltd.

HY-H Series – Mass production automatic operation cutting machine

Assembled in China, this low-cost automatic cutting machine maintains high-accuracy and high-speed performance cutting while keeping running costs to a minimum and enabling ease of operation. Moreover, unparalleled levels of reliability are achieved through use of precision electronic and operational parts, most of which are made in Japan.

HY-H1705

The standard cutting machine; Accurate high-speed cutting; From small layer to multilayer Suction conveyor system: By improving the conveyor structure and suction mechanisms, quick and accurate material transportation is implemented. Absorption stabilization system: Changes in suction power are controlled via sensors during cutting. The machine self-adjusts to maintain the optimal level of suction. The suction force will be adjusted to deal with delicate material or foam material. Knife cooling equipment: By spraying the knife cold during cutting, adherence of materials is avoided

Features of the HY-H Series:

- Tank-type vacuum box: By putting the conveyor in a vacuum box, the vacuum efficiency is improved, noise is lowered and power is saved.

- Foil-type grinding equipment: Grinding is uniformly done to keep the knife sharp and long lasting. Inverter controlled power-saving vacuum motor the optimal vacuum power for each material is adjusted by the vacuum motor, saving power at the same time.

- Self-diagnosis function: When the machine stops, the cause is displayed on the monitor • There are 5 lamination types at compression: 10, 30, 50, 75, 110mm. • There are 3 material lengths: 1700mm, 2000mm, 2300mm • Conveyor type cutting table: There are 2 table lengths: 2000mm and 3300mm.

HY-S1624 – Suitable for a diverse array of cutting material

Features of the HY-S Series:

- Area control vacuum zone: Vacuum only occurs in cutting zone, leaving easy pick-up of parts in other areas

- Foil-type grinding equipment: The knife is made for long-lasting sharpness.

- Paving paper-less system paving paper is unnecessary as a high-accuracy cutting table brush is employed for a precision cut

- Self-diagnosis function: When the machine stops, the cause is displayed on the monitor.

Automatic spreading machine: A smooth spread without material stress

SM Series (Bucket-type fully automatic spreading machine

The width-feeding function is installed in 3 places. This combined with the conveyor-belt mechanism allows for a perfectly clean, tension-free spread. In addition, the servo motor running- and send-off mechanisms perform a high accuracy spread. Grinding of the cutting device is automated in order to maintain a sharp cutting edge. Features of the SM Series:

- A tension-free spread is made possible by the conveyor belt anti-system

- The position of the bucket device is set low so any man or woman can unload the material easily

- The servo motor’s running and material send-off mechanisms allow for accurate spreading

- The width-feeding function is installed in three places for a clean, stress-free spread

- Grinding of the cutting device is automated, maintaining a sharp cutting edge

- The spreading length can be easily set from any position on the spreading table by the gear belt andthe encoder specification

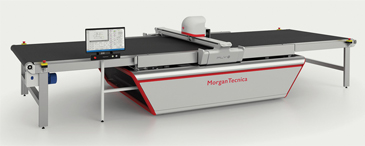

Automatic cutting machines by Morgan Tecnica

Morgan is a group of companies, based in Adro (Brescia), Italy. Morgan Tecnica Spa and Morgan Dynamics are responsible for the design, creation and manufacturing of machinery/software/products used to automate the cutting rooms of many industries around the globe. It has automated processes in all areas of the cutting room from fabric loading, automatic/intuitive spreading, label printing and state-of-the-art cutting machines, all being linked together with our single and multi-level tables.

Morgan is a group of companies, based in Adro (Brescia), Italy. Morgan Tecnica Spa and Morgan Dynamics are responsible for the design, creation and manufacturing of machinery/software/products used to automate the cutting rooms of many industries around the globe. It has automated processes in all areas of the cutting room from fabric loading, automatic/intuitive spreading, label printing and state-of-the-art cutting machines, all being linked together with our single and multi-level tables.

Morgan Machinery Automatic cutter Next 2

Next 2 is Morgan’s newest high-ply cutting machine. Available in versions 5,7 and 9 cm compressed. Next 2 is the answer that meets all the cutting room production needs. From apparel to furnishing, from automotive to accessories manufacturers. Design and A.I. (Artificial Intelligence) are the key words of a machine that was created to think in the future. Thanks to the abundant implementation of sensors and sophisticated algorithms, Morgan Next 2 is the first machine with Artificial Intelligence that allows the best self-handling of processes such as sharpening cycles or real time speeds control. This technology guarantees the highest quality combined with the maximum productivity and the lowest running costs. Next 2 is also able to self-detect (Auto-diagnosis system) all the operating anomalies by drastically reducing breaks and machine stops.

Technical Specs: • Max cutting thickness 7 cm compressed • Power plants 10 kW + 37 kW • Average power consumption approx. 22 kW • Standard cutting window 180 cm • Available width 180 – 220 cm • Standard 6000rpm • Environmenttemperature from 10° to 40° C • Humidity from 30 per cent to 80 per cent without condensation • Voltage 400 V 3Ph 50/60 Hz.

PLY 1 Single ply cutting machine

From natural woven fibres to technical textile and composites, from apparel to upholstery, from the automotive to the graphic industry Ply1 is the answer that meets all these needs and many more. Ply 1 is the latest Morgan single ply cutting machine with unique performances. Thanks to the new generation of linear motors Ply 1 can reach speeds and accelerations that make it the fastest in its category. High performance, maximum precision, minimal maintenance, modern design and innovative software are the distinctive features of Morgan Ply 1.

From natural woven fibres to technical textile and composites, from apparel to upholstery, from the automotive to the graphic industry Ply1 is the answer that meets all these needs and many more. Ply 1 is the latest Morgan single ply cutting machine with unique performances. Thanks to the new generation of linear motors Ply 1 can reach speeds and accelerations that make it the fastest in its category. High performance, maximum precision, minimal maintenance, modern design and innovative software are the distinctive features of Morgan Ply 1.

Technical Specs: • Power plants 4, 5 + 4 kW • Average power consumption 3,5 kW • Acceleration up to 3G • Speed up to 180 m/min • Standard cutting window 250 cm x 180 cm • Humidity from 30 per cent to 80 per cent without condense • Voltage 400V 3Ph 50/60Hz.

Gemini CAD Systems presents latest cutting solution

Gemini CAD Systems is a leading global supplier of technology for industries working with soft flexible materials such as textile, composites or leather. Given are some of its latest technologies.

Gemini Pattern Designer

It is the flagship of Gemini CAD Package. X17 version is the result of company’s 15 years of experience in the field and the continuous innovation invested in the product, to respond to the challenges and needs of more than 20.000 end-users.

- Pattern development: Gemini Pattern Designer x17 features all options for shape construction, depending on user’s preference: free, assisted and parametric methods, or any combined approach. The quality is in details, and to handle such details it has now 24 types of seam allowance customizable corners, a unique Folds Editor to handle multiple and complex folds with 3D folding visualisation and library and the most advanced set of tools for Notch Management.

- Grading: It has the most powerful and comprehensive Grading System ever seen on the market, yet easy and simple to understand and to use.

- Mesurement & Check: Packing sizes in a point or along a direction or Mary or Walking a piece onto another to check the matching, are now much easier due to the Widget control, a simple tool to help execute operations directly on the piece surface, allowing a fast and efficient teraction.

- Pattern decoration & manufacturing instructions: It features a full set of tools for decorating the patterns and including information useful later manufacturing process, such as: Text bullets, text along path, information cartridge, accessories, graphical representation, seam line technical representation, etc.

Gemini Spread & Cut Planner

Gemini Spread & Cut Planner is the link between the design room and the cutting room. It provides fast and high-quality automatic or interactive optimisation for the spreading and cutting operations. The operator inputs the quantity of products ordered by the client for each model, size and fabric, and some general settings regarding cutting conditions such as the preferred spreading length, the maximum number of sheets in the lay or the fabric width. This information can also be retrieved automatically from the company’s ERP system. The application can automatically generate the most efficient plan for the product grouping and distribution, so a minimal number of markers and lays are needed to obtain theordered quantities.

This automatic operation doesn’t take more than 1-2 minutes. The user may choose among several automatic and manual or semiautomatic lay planning & strategies, so the best results are achieved every time. The entire order, containing the cutting plan and a collection of lays and optimised markers are stored in one centralised file, easy to store and share. Some other highlights are: Automatic and manual lay definition, Automatic order optimization, Cutting room order report, Export for plotters, cutters, Export for other CAD systems, Integration ERP systems using OTX open format.

ThreadSol presents Solutions for Enterprise Material Management

It is high time apparel manufacturers realize the gravity of targeting fabric cost to increase profits. In order to stay competitive, they need to achieve this through automation of processes by adopting advanced solutions,” Mausmi Ambastha, Founder COO, ThreadSol. The world has transformed, trades have advanced. With the boom of the new era, apparel business all over the world has witnessed majestic shifts. To manage this change, apparel manufacturers need to accelerate their operations and re-evaluate the legacy of manufacturing practices.

The dynamic technologies being introduced each day is a sign of constant development. ThreadSol- the pioneer in enterprise material management for the sewn products industry- takes pride in constantly challenging the present and being part of such a revolution. ThreadSol’s outlook is to introduce technologically driven products to drive manufacturing by targeting material cost and differentiate from the extremely competitive environment.

With its innovative solutions- intelloBuy, intelloCut, and intelloTrace, ThreadSol demonstrates an entire range of enterprise material management solutions, which can help apparel manufacturers save material cost and boost profits, in an industry that is heavily dependent upon economic priorities. IntelloCut is a material planning and optimisation solution for the sewn products industry. The flagship solution of ThreadSol has been successfully deployed in 120+ factories worldwide, who plan 1 bn pieces every day.

With the help of its advanced algorithms, IntelloCut gives the most optimized cutplan, roll plan and lay plan, in just one click. The cloud computing structure helps to access the solution from any point. It also offers a feedback system which works like GPS: any variations on floor and the plan can be changed with a single refresh button. With over 150+ features, intelloCut is a product ahead of its time and truly defines the new age technology. In a constant effort to improve, ThreadSol has introduced intelloGreen: A tablet application which replaces on-floor printed layslips. The application is based on cloud computing and takes data from intelloCut, transforming business from traditional to environment friendly.

The advanced reporting structure of IntelloCut provides an edge to the manufacturers to get complete control over factory’s practices through intelloMobile: world’s first fabric utilization reporting app. IntelloMobile provides 100 per cent real-time traceability of fabric, with all reports on mobile phone.

IntelloBuy is a material estimation solution for the sewn products industry. It is the second product by ThreadSol, taking the enterprise material management model of the company to the next level. IntelloBuy gives accurate buying consumption for a particular style which saves millions of dollars of material cost at the buying stage, every day, for manufacturers worldwide.

intelloBuy accesses factory historical database and allows the user to add exact wastage from factory floor to generate the most accurate fabric requirement. This can save up to 10 per cent fabric cost, ultimately boosting profit. Through the advanced reporting offered by intelloBuy, one can get details of the consumption calculation for different style/ order, vendor details for width/ shrinkage, factory process loss, buyer’s details of size-wise order break-up etc.

MySize unveils new measurement technology

My Size, Inc. has developed a unique measurement technology based on sophisticated algorithms and cutting edge technology with broad applications including the apparel, e-commerce, DIY, shipping and parcel delivery industries. This proprietary, patented technology is driven by several algorithms which are able to calculate and record measurements in a variety of novel ways.

My Size, Inc. has developed a unique measurement technology based on sophisticated algorithms and cutting edge technology with broad applications including the apparel, e-commerce, DIY, shipping and parcel delivery industries. This proprietary, patented technology is driven by several algorithms which are able to calculate and record measurements in a variety of novel ways.

My Size, Inc. MYSZ, a developer of proprietary, smartphone measurement applications, intends to release a new measurement solution technology that will revolutionise the way consumers shop for clothing online. The new technology is currently in the testing phase at several Israel-based academic institutions, and to date, has shown promising results under lab conditions.

Its innovative technology has been designed to allow consumers to measure themselves using their smartphone and then be matched with an online apparel item in their size. It believes that this technology has the potential to significantly reduce the margin of error for customers purchasing the wrong size apparel online.

Its R&D Engineers have developed a system that pulls data from anthropometric databases, which is then combined with studies on body measurements of diverse populations groups. MySize’s proprietary methodology combines this data with the measurements obtained from an individual via the smartphone app to estimate the circumference of different body parts that determine the size of garments.

In order to help consumers determine the key body measurements needed for fitting apparel purchased online, MySize invented a simpler and more accessible three step process: Perform convenient body measurements using a smartphone. Predict the body circumferences required by the retailer size-chart using the MySize’s new proprietary algorithms.

Recommend to the user their appropriate garment size according to the retailer’s size chart. Recording accurate and detailed body measurements via traditional methods is generally difficult. The main traditional methods involve advanced 3D scanners, or manually using multiple tape measures and callipers. In both cases, they can be expensive, require expertise to operate, and are not available to consumers. My Size is the only company that is able to do that based on recently awarded patented technology that uses actual body measurement. My Size’s patent has been approved in several countries, including the US.

“My Size has developed an innovative solution that will enable consumers to shop for better-fitting apparel online, across multiple vendors, and get their correct size, based on their individual smartphone-based body measurements. This level of accuracy and convenience is not offered by any of our competitors,” said My Size CEO, Ronen Luzon. “The US e-commerce apparel market alone is over $72 bn of the total e-commerce market of $394 bn, and we believe that the My Size solution will help reduce returns to retailers due to sizing issues, thereby benefitting consumers by assisting them to purchase apparel that fits their specific size.”

Sakho Technocraft presents automatic cutting machines

Sakho Technocraft Pvt. Ltd. is providing sales & service of Korean make Sakho Brand special type industrial sewing machine & attachments. The company provides best machineries and service to garment industries with its highly dedicated technical & commercial. Its automated garment machineries & attachments are well known across the world for its low cost, best quality, durability, outstanding performance & services.

SA-2000A – Fully Computerised Automatic Cutting (Slitter) Machine

It suitable for cutting fabric, chemical fabric, rubberized fabric, adhesive tape, leather, paper, interlining, etc.

Product features:

- Uses microcomputer digital programming technology, and has touch-screenoperating interface. It is very simple and convenient to use it

- Uses full-covering design and dust vacuuming exhaust features, makingoperation safer and environment friendly

- With unique cutter repairing device, the time of repair cutter can be set at will so that the cutting edge can maintain sharp

- The same material can be cut out six kinds of bundles with different width

- Spindle, cutting rotating speed and X axis moving speed can be set optional

SA-16090DI / 14090DI SA-12080DI / SA-180100DI SA-160100DI Double head laser cutting machine with automatic head distance adjusting

Product features:

Auto double head laser cutting machine is capable to automatically adjust the head distance according to the design sizes & scope, which saves the time & work of manual head distance setting; And it automatically controls the laser emit according to actual cutting/engraving requirement, which avoids repeat working and saves laser energy. Compared with traditional double head machines, auto double head series greatly realises the automation of laser application, which saves the production cost and enhances the working efficiency.

Applicable Industry:

Garment, leather, cloth toys, embroidery patch cutting, mould, arts and crafts, advertising, decoration, packaging, print and so on.

Advance network and High-speed sewing systems by Juki

Juki Corporation, the global leader in industrial sewing machines, with the commitment to “seam quality” is poised to enter a new era with Juki’s nextgeneration sewing system. The company recently launched its DDL-9000C-SMS (Digital Type) direct drive, high-speed, sewing system with automatic thread trimmer. Given are some of its highlights:

Computer-controlled vertically and horizontallydriven feed mechanism

The world’s first feed mechanism which is driven both vertically and horizontally has been computerised. The feed mechanism changes its feed locus in accordance with the material. As a result, the optimum adjustments can be achieved only by setting data on the operation panel. Furthermore, the vertically-driven feed mechanism helps keep the length of the thread remaining on the material after thread trimming constant.

Remaining thread at the end of sewing reduced to 3mm

A both-blade driven rotary knife system is adopted. The knife intersects with the thread to trim it just beneath the needle entry point. Since the knife ensures constant length of needle thread, the length of thread remaining on the material after thread trimming is, unlike thread trimming with the thread tensed, also constant. The Juki DDL-9000CSMS inherits JUKI’s thread trimming technology to allow the thread trimmer to start up as soon as the pedal is depressed.

Sewing Machine management utilising “IoT” (Internet of Things

Data adjusted in a sample-making workshop etc. can be transferred without contact to the sewing machines in your factory using your tablet. (USB port is provided as standard)

LK – 1903BNB Button sewing machine with the bird’s nest preventing / shorter thread remaining functions which eliminates thread nipping work

Users who are conscious about the finished quality of products manually nip, with scissors, the thread remaining on the material after thread trimming at the end of sewing, Now, the button sewing machine with the bird’s nest preventing/shorter thread remaining functions saves such users the trouble of nipping the thread, thereby preventing the sewing product from being damaged by manual threadnipping with scissors.

The sewing machine eliminates so-called ‘’bird’s nests’’ (thread tangling in on the wrong side of the material at the beginning of sewing). The thread is retained at the beginning of sewing and any excess thread is trimmed during sewing. As a result, the length of thread sewn in the seam is shortened, thereby achieving high-quality sewing performance while preventing thread from tangling in on the wrong side ‘’of the material.’’

Length of thread remaining on the material at the end of sewing has been reduced to 2 mm or less*. The newly-developed shorter-thread remaining mechanism trims the thread shorter after the regular thread trimming operation. Additionally, thread waste produced by thread trimming is withdrawn by suction. Thanks to this mechanism, the trouble of manual thread nipping is avoided.

The machine achieves sewing speed of 2,700 sti/min The machine’s thread trimming etc. have been increased to significantly shorten total cycle time. The machine is provided as standard with 50 different sewing patterns at higher productivity. The LK-1903BN is a lockstitch button sewing machine which is not only applicable to many different sewing specifications but also able to carry out cycle sewing and produces high-quality seams.

JaNets – Juki advanced network system

JUKI Advanced Network System optimises the overall production of the automatic SMT line. A client PC delivers production programmes to any machine operating within the line and administers all the data at the same time. Data for the control of each machine as well as for management of the complete production line, are collected and consolidated. Subsequent EDP systems such as enterprise resource planning systems can be connected with an optional, external export function. Given are some of its highlights:

What is JaNets?

- Collect production data by RFID

- Based on a shop floor control system for whole factory

- Visualize a sewing section (the most machines and operators works and difficult to see their work), then help resolving problems and control

- Transport sewing machine data to digital sewing machines

- Capable with not only digital sewing machine but existing machine

Real-time monitoring: Production data

- Real-time monitor production progress(Group, Order, Operator)

- Real-time capturing delaying with a plan

- Multi-level KPI analysis (workshops, production groups, workers)

Real-time monitoring: WIP, Line balance

- Real-time feedback “WIP Products” trace

- Clearly know underbalanced production line

- Management takes timely adjustment measure

- Reduce the increased costs caused by “WIP Product”

Support orders receiving

- Provide strong data support for reasonable orders receiving

- Provide detailed analysis for factory’s productivity

- Make management people know well about the spare capacity distribution

- Provide decision data for avoiding overload of orders and unsaturated orders receiving

Quality control

- Make management people know real-time and onsite quality problem and promptly make a correct

- QC worker input on-site QC result

- System real-time captures and analyzes on-site QC data

- Management take immediate measures to resolve the quality problem

- Reduce irreparable loss caused by defect products

Analyze working

- Analyze operator motion can display sewing machine speed and start/stop time

- Production board

- Function of dashboard which can check product situation not only PC but also smart phone and tablet.

- This is simplification function real time monitor can get list

Loiko Global presents Button Feeder attachment

As we all know that most of the time the garments packing get delay due to pending of Button Hole and Button Stitch operations. To finish these operations customer do overtime, for operate these machines we need skill operators. Just to deskill the Button stitch operation the company developed Button Feeder attachment (SAKHO MODEL ST-12 MADE IN KOREA). Normally Button Stitch operator can attach 600 to 700 Buttons per hour in shirt production, if customer installs its Button Feeder in the same Button stitch machine they can attach 1200 to 1400 Buttons per hour depend upon the Button stitch machine condition. It means almost double production, and not required any skill operator.

The beauty of Button Feeder (SAKHO MODEL ST-12) is we can install in any Electronic Button stitch machines without any alternations. The advantage of our Button feeder is reducing the manpower, reduce over time, increase the productivity, and reduce break down time. In my opinion in-future 70 to 80 per cent customers will order button machines with button feeders. The ROI of our button feeder will be around 12 months. It is very proud to say that last year we got 100 Button Feeders order from one customer in Bangalore, and also happy to say that most of the customers using our SAKHO Button Feeders because of the technology, user friendly, quality, performance and service support after sales.

Brother presents latest sewing solution

Since its inception in 1908, Brother has been at the forefront of products innovation, dedicated to delivering superior and innovative sewing technology to its customers. Given are some of its latest innovations:

S-7250A Single Needle Direct Drive Lock Stitcher with Electronic Feeding System and Thread Trimmer

DigiFlex Feed -Direct Electronic Feed Control

DigiFlex Feed, which is world’s first equipped on S-7300A and highly evaluated in the market, digitalizes feeding system and resolves various sewing troubles without adjustment work.

- Improvement in the reduction of needle breakage and productivity

- Simple select and smooth sewing without material slippage

- Excellent sewing quality that’s easy to get proper thread tension in accordancewith several materials

Needle breakage prevention with Brother own 3 functions

- Optimization of fabric feed timing by changing feed motion of DFF: Fabric can be feed at an appropriate timing so that needle won’t break even during thick material sewing.

- Change from mechanical control to stepping motor control by equipped DFF: Compared to conventional mechanical control, the stepping motor control makes the response of reverse sewing quicker and reduces needle breakage.

- Equipped with needle prevent breakage function while reverse sewing: Sensing needle position and controlling proper feed timing that prevent from unreasonable reverse sewing as needle breaks automatically.

A variety of functions realise ease of use and ideal sewing quality

- Beautiful stitching without puckering: DFF realises appropriate thread tightening in relation with the fabric and reduces puckering

- Stress relief at reverse sewing: Because the reverse sewing is changed to motor control, vibration and noise are suppressed. It contributes a stress relief

- Reduction of hanging fabric: By arranging rubber on the back side which hadbeen installed at the four corners of the bed of the sewing machine on the surface, it becomes easier to handle the fabric

- Oil staining prevention: The closed oil tank enables clean sewing more than conventional model’s that does stain sewing material. The minimum lubrication system prevents problems such as oil leakage and oil scattering drastically

- Easy operation with a simple panel: You can change the stitch length and sewing speed easily. In addition, it is possible to set the stitch length as a numerical value, and the reproducibility of sewing is improved

Productivity improvement by improving production management with IoT

- Productivity improvement with IoT: NEXIO series are IoT applicable models. The visualization by connecting sewing machine and computer technology enables the customer to analyze, manage processes and speed up productivity improvement and maintenance work

- Easy and secure data management with USB: Data transfer to other sewing machines and software upgrade can be done with USB memory easily

KE-430HX/HS: Electronic Direct Drive Lockstitch Bar Tacker (Short Remaining Thread Spec)

With the world’s top-class sewing speed and prevention of thread breakage with a needle cooler, the machine has increased productivity. It also has superior sewing quality, usability, and reduces maintenance cost.

With the world’s top-class sewing speed and prevention of thread breakage with a needle cooler, the machine has increased productivity. It also has superior sewing quality, usability, and reduces maintenance cost.

Productivity improvement by World’s Top-class Sewing Speed and IoT

- Overwhelmingly Superior Productivity with Sewing Speed 3,300sti/min: KE- 430H provides 3,300sti/min (BE-438H: 2,800sti/min) and contributes to enhance productivity.

- Needle Cooler Prevents Thread Breakage: Needle Cooler* prevents thread breakage, it enhances actual sewing speed by 10%. It provides high productivity and quality.

- 3Reduction of Disposition of Thread Ends (Short Remaining Thread): Thread trimmer driven by stepping motor cuts the thread shorter, stable and quietly than conventional mechanical thread trimmer. It reduces hand trimming work after sewing. Also, the thread nipper, equipped as standard*, minimises thread cast off at sewing start and bird’s nest.

- Productivity Improvement with IoT: This is IoT applicable model. The visualization by connecting sewing machine and computer technology enables the customer to analyze, manage processes, speed up productivity improvement and maintenance work.

Beautiful and Highly-reproducible Sewing Quality

- Thread Tension can be Set as Numerical Value by Digital Tension: You can adjust the tension appropriately for the material being sewn without relying on individual feel. It provides higher production management and sewing reproducibility.

- Clean Sewing without Oil Stain: HX models are semi-dry type and they supply constant clean oil only to the shuttle hook, there is no concern of oil staining. HS models are minimum lubrication and they supply limited oil only to the needle bar and thread take-up to prevent oil from being dispersed, realizing clean sewing for your valued product.

Superior Usability as everyone can Use easily and reliably

- User- intuitive Color LCD with Touch Panel: Equipped the Color LCD with touch panel that indicates display items with illustration icons, offering use-intuitive operation. It is very easy to set the cycle programme, along with sewing patterns, sewing speed, and magnification. The upper thread tension can be stored easily as user programmes.

- USB Port is equipped: Data transfer to other sewing machines and software upgrade can be done easily with USB memory

- Reduction of maintenance cost as there is no need for grease-up work: There is no need for grease-up work at the connecting rod because it adopts oil lubricating, and reduces maintenance work

- Low noise and low vibration for stress-free operation: The noise and vibration are minimised by reducing impact during thread trimming. Operators can sew conformably without fatigue and stress.

Headbag Process reliability for up to 3,500 x 1,000 mm with PFAFF

The PFAFF brand stands for 150 years of industry experience and expertise. PFAFF has been a leading innovator in industrial sewing and welding solutions for decades. By innovations and the product development the customers trust in their products and service worldwide. Trust in a strong international partner as well and catch up on their variety of products and competences.

When manufacturing high-quality car seats (decorative stitching) and airbags (functional and safety-relevant seams), the manufacturers (car manufacturers and automotive suppliers) count on the performance, quality and process reliability of the KL 110 CNC-controlled sewing unit. The customer list of the machine reads like a “Who is Who” of the automotive industry featuring prestigious brands from all continents. Particularly, when it comes to manufacturing airbags, the industry has in recent years become very sensitive due to a scandal (deaths, exploding airbags, recalls) involving a well-known Japanese airbag-manufacturer. The manufacturers demand solutions with customized individual and process-reliably controlled applications that ensure maximum reproduction of their airbags. Certainly one reason why the KL 110 has become a true “market performer” is, because the manufacturers trust the technology and knowhow of KSL based in Lorsch/Germany. Over the past 2.5 years more than 100 systems were sold around the world. KSL documents and implements all individual customer requests/ applications during the project phase. Over 80 of these machines were assembled at the Pfaff Industrial-facility in Kaiserslautern. Here the space capacities for production and assembly are bigger.

When manufacturing high-quality car seats (decorative stitching) and airbags (functional and safety-relevant seams), the manufacturers (car manufacturers and automotive suppliers) count on the performance, quality and process reliability of the KL 110 CNC-controlled sewing unit. The customer list of the machine reads like a “Who is Who” of the automotive industry featuring prestigious brands from all continents. Particularly, when it comes to manufacturing airbags, the industry has in recent years become very sensitive due to a scandal (deaths, exploding airbags, recalls) involving a well-known Japanese airbag-manufacturer. The manufacturers demand solutions with customized individual and process-reliably controlled applications that ensure maximum reproduction of their airbags. Certainly one reason why the KL 110 has become a true “market performer” is, because the manufacturers trust the technology and knowhow of KSL based in Lorsch/Germany. Over the past 2.5 years more than 100 systems were sold around the world. KSL documents and implements all individual customer requests/ applications during the project phase. Over 80 of these machines were assembled at the Pfaff Industrial-facility in Kaiserslautern. Here the space capacities for production and assembly are bigger.

The KL 110, a freely programmable CNC-sewing unit featuring a turning head, is offered either in a one- or two-needle version and generates up to 2,800 stitches per minute. Due to the tangential orientation of the sewing head into random sewing directions, complex seams may be produced in top quality as back stitch or chain stitch. At the Texprocess 2017 in Frankfurt, the machine was presented with a barcode-scanner system to record data in multiple applications and immediate analysis via the HMI-operator panel. The turning head-technology is also used for applications beyond airbags resp. car seats e. g. for sophisticated decorative stitching operations on a KL 311 (virtually identical in construction to the KL110) at a European manufacturer of luxury goods. Likewise, the door panels and seats of the new model of a British luxury car manufacturer are sewn using a KL 311 with turning head.

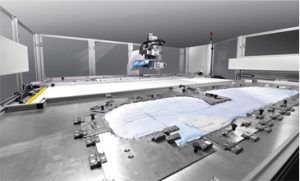

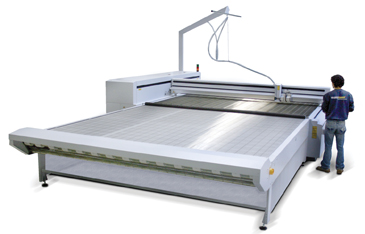

eurolaser presents textile cutting in large format

The company eurolaser from Lüneburg (Northern Germany) has revolutionised largeformat textile processing with the laser cutting machine 3XL-3200. Blinds, curtains, shutters and gates require clean textile cuts in extremely large formats. Here, eurolaser is the only supplier in the upper quality segment that offers processing tables with a width and length of up to 3.20 mtr. The precise roll feeding and the tension-free transport via the specially developed conveyor ensure maximum reliability. eurolaser system tables combine Swiss precision with German engineering. They are fundamentally modular and are configured individually for customers and their applications. Consequently, various requirements for the processing can be taken into account. For example, engravings, markings or labels can be added in just one single production run. Besides, other tools e.g. for optical recognition on printed materials can be integrated.

eurolaser’s durable and high-precision laser cutting systems can process a variety of materials, e.g. plastics, foams, textiles, adhesive foils, woods, acrylics, composites and much more. The high-quality components guarantee reliability, extreme long service life and a positive price-performance balance for the user. By acquiring a eurolaser system, a long-standing partnership with the manufacturer will be established. This ensures competent and fast support, the supply of high-quality materials and spare parts as well as the ongoing option for expansions. The eurolaser-ACADEMY offers all necessary user seminars concerning efficient and environmentally friendly operation and maintenance on-site. In addition, there are user tips, further developments and new problem solutions so that manufacturing processes can be further optimised or extended.

Pegasus releases “LaRgo,” the FS700P series

Pegasus Sewing Machine Mfg. Co., Ltd. has released “LaRgo,” the FS700P series equipped with a right and left independent differential feed adjustment mechanism, hereinafter called “LaRgo ”. The new product, LaRgo is most suitable for sewing functional fabrics, employed for sportswear and similar garments. The focus on sportswear with designs employing mesh fabrics with excellent breathability and stretchable fabrics with excellent stretch ability has increased markedly in recent years. However, these designs require highly skilled operators when sewing these fabrics with different features. In order to solve these problems, Pegasus has developed the LaRgo, equipped with the world’s first, right and left independent differential feed adjustment mechanism. Thanks to these excellent features, this flatseamer consistently produces beautifully finished products regardless of the skill of the operator.

No matter what the circumstances, no matter the operator. Needle and threads advance smoothly at the sewer’s own pace. Stitching is straight and beautiful without worry. This precise and soothing rhythm prevents right or left misalignment of the fabric. LaRgo, with needle and thread, seams smoothly, drawing on long cultivated technical skills and the daily genesis of imagination. Given are some of its highlights:

- Easy to seam different fabric material: Effective to seam different right and left fabric material such as sportswear

- Reduce operators’ manual adjustment: This unique feature enables operators to seam two different types of fabric easily

- Stable quality and improvement of productivity: It keeps stable sewing result not depending on operators’ skills, which contributes to stable quality and improvement of productivity

Kansai Special presents latest sewing machines

Today, in an era of great innovation, the people’s demand has been sophisticated and greatly diversified, and Morimoto Mfg. has remained adaptable to their needs by foreseeing ahead, knowing the market, and going forward. Its mission is that Morimoto Mfg. expands the alternative global network which is based on its standard framework.

JJ3014GH-01M-2X4 Kansai Special launches New Overlock Machine

JJ Series is 1~3 needle, overlock and safety stitch machine that contains major features and is user-friendly.

High speed

- Max. 8,000 rpm

- May be vary in subclass machines

Easy maintenance

- Closed Type (Fully sealed Direct Drive Needle Bar Mechanism

- Micro Adjustment for Looper

Low noise, low vibration

- New design of casting (”S” Line)

- DLC Coated Needle bar & DLC Coated Upper Looper Mechanism

NW8803GD 3 Needles 5 Thread Flat Bed Interlock Top & Bottom Cover Stitch Machine

Kansai Special launches New Interlock Machine. NW Series with added features, user-friendly.

Multi operation (in GMG Model)

- Plain Seaming, Tape Binding,

- Cover Stitch (Center & Left), He

Easy maintenance

- Needle bar Stroke adjustment (Light to Heavy 31mm,33mm)

- Micro Adjustment for Looper

- Convertible Front Cover (Tape binding)

MEGASEW presents latest industrial sewing machine

Since the establishment in 2005, Ming Jang Company has perceived with its sharp insight the gradual adjustment and change of setting up their manufacturing equipment in garment factories to be in accordance with the inclination of change in fashion trend and rising requirement for wearing comfort in consumer markets. The company continues working hard to enable MEGASEW machines and related service to completely accomplish our core value – in search of “The art of sewing.” 4th gen. of MJ101TX was recently launched by the company. Given are some of the features:

Since the establishment in 2005, Ming Jang Company has perceived with its sharp insight the gradual adjustment and change of setting up their manufacturing equipment in garment factories to be in accordance with the inclination of change in fashion trend and rising requirement for wearing comfort in consumer markets. The company continues working hard to enable MEGASEW machines and related service to completely accomplish our core value – in search of “The art of sewing.” 4th gen. of MJ101TX was recently launched by the company. Given are some of the features:

Machine Frame is Directed and Tilting Slightly to the Right Side

Operators do not need to force their bodies forward and can easily be with wide sewing view. And don’t need to put their chests against the back of Machine frames, it’s annoying heat will no longer be transferred to bodies!

- Operators are able to relax and sit straight up to perform stitching easily

- The weaknesses of Normal Flat Seaming Machine: While sitting straight up as usual, operators can only be with narrow sewing views

- Operators need to lean their bodies towards the left to get wider sewing view

Advanced Generation Design – “Triple Differential Ratio Feeding’’

On normal flat seam machine, if you want to adjust coarse stitch, you need to open up a big screw on the left side of the machine, and move up or down the feed Rocker Link, Now on MJ101TX the old-fashion hidden mechanism is reengineered and exposed on the right side of the machine, and with this change, the stitch adjusting is made visible and terribly easy. Furthermore, a revolutionary “Triple Differential Ratio Feeding’’ mechanism is created, by being supported by original patented Dual Differential Ratio Feeding in MJ62GX/GXD/DX machine series. Because of this new creation, the challenges for a flat seaming on differentstretching, different-weighted and different material of fabrics can be satisfyingly overcome!

To move out hidden bottom thread CAM to external type

The most weakness of hidden Bottom Thread CAM is it has restricted and sacrificed the ease of threading, maintenance, and the trouble-shooting while thread is entangled. The innovative design of MJ101TX not only eliminates the above-said problem, but also assures of a neat, clean and beautiful stitch because the Bottom Thread CAM is moved closer to sewing area where the looper is located.

Adjustable Front Needle Guard

MJ101TX adopts adjustable front Needle Guard design to protect only the four sewing needles but not to touch the retainer needle to solve the retainer needle easy breaking issue.

Superior Oil Providing and Withdrawing System

A well-designed oil providing and withdrawing system is decisive both to a longer lifespan of parts and machine and to the possibility that stitching speed can be enhanced. The innovative design of MJ101TX is featured with two high-efficient oil providing and withdrawing Oil pumps, which can make sure the oil can be drawn back by independent pump form Needle Bar and sewing Cylinder’s sewing area after the parts are perfectly lubricated.

SCD – Unprecedented Stitch Condenser for Flat Seaming (Optional)

The main purpose of SCD device is used to prevent the thread ends from breaking up. This condensed stitch provides a similar function of bartacking to step the thread ends from slipping away or taking off, so reworking will not be required!

Automatic placket setting workstation by Robotech Automation

Robotech A.G. is the leading automation machine manufacturer in Turkey with its high-technology products, experienced employees, customer-focused servicing policy and international vision. The company was founded in 1997 by Computer Engineer Hüseyin Çetin in Istanbul in order to make designs and production of automation sewing systems.

XP 7100 – IX – Polo Fly Automat

XP 7100 – IX Automatic placket setting workstation. The machine fully automatizes a series of sewing placket processes. (Hidden Placket)

Technical specifications:

- Brother direct drive sewing head

- Beijer electronics Windows Based 256 mn colour supported touch screen control panel

- Easy to use, with pictures on the operator panel and with 50 different programming

- Sequential/cycle programming for different front fly models

- PLC Control Unit

- Motion Control Unit with X/Y Axis Programme

- X Axis based Teco (WestingHouse) AC Servo Motor & Driver Controlled Clamp Unit

- Sewing head moving on the Y axis

- Programmable start and end back tack or optionally adjustable stitch condensing

- Automatic Thread Cutting and Cleaning System at the end of sewing

- Single and double blade cutting on the same machine for different placket models

- Identification through the panel for all kind of Fly Model with Angular and Different Stitch Sizes

- Special Sandwich Clamp System to prevent fullness while sewing

- Standardization of sewing style and size (within max. 26 cm sewing length)

- Vacuum system to facilitate the placement of fabric on machine

- Clamp Fabric Stretching Unit to increase Cutting and Sewing Quality of Fabric

- Especially Designed Pneumatic controlled Bearing Foot System to increase Cutting Quality for Double blade cuts

- Vacuum Motor Connection Unit

- Special Designed Stacking Unit

- Error Detecting Systems

- Thread monitor

Latest sewing solutions by Silversun

Silversun is well established and reputed brand providing high quality latest technology with an edge at cost effective investment. It has machines for every sewing application with production division in Taiwan and China. The quality and innovation are reason behind Silversun success.’

Silverun has introduced Taiwan manufactured SMX – 6372/PUT-SPU/TW, high end technological four needle six thread feed of arm interlock flat seam machine. The machine is equipped with both side fabric trimmer, pneumatic thread trimmer with auto lifter, suction device and Ho Hsing’s i70 direct drive system. The unique and versatile mechanism deal with wide range of fabrics to provide optimised sewing for various applications. The both side fabric trimmer results in smooth and sharp trimming of waste fabric to enhance sewing quality.

The pneumatic thread trimmer easily cut the extra thread to collect in its suction device and has auto foot lifter for operation ease. The compact Ho Hsing’s i70 servo system is power saving powerful output system with low noise, anti-vibration with more cost saving advantage.

Another new introduction is SMX 1790 S/K intelligent computer direct drive button hole series with latest Daiho computer which provide button holing solutions to every type of fabrics and application. The intelligent computer has inbuilt patterns along with memory to store more in its memory for easy use.

SMX 1903A is 2 in 1 high speed computerised direct drive lockstitch button stitch and bartack sewing machine. This unique optional mechanism to change to bartack is easy and cost effective solution for dual performance and application. Silversun has diversified models for each sewin application with option to have basic models to high end technology direct drive system machines with all available optional devices and attachment.

Hot air sealing and Ultrasonic trimmer machines by H&H

H&H Asia Group Ltd. is specialised in thermoplastic technology for sew free adhesive and waterproofing applying on the industries of clothing, bags, shoes, medicals, gloves,… that include waterproof seam sealing, sew free pocket adhesive, zipper bonding, front zip sealing, fabric joining, line bonding, overlay taping, and also adhesive backing for woven label and embroidery. Given are some of its latest innovations:

AI-001 – Hot air sealing machine

(Optional Available Lower Pedestals)

- New generation • Stretch fabric ready

- Narrow tape ready • 3-layer sealing mode

- 30 per cent faster • 5 per cent tape saving

- Software upgradable • Hardware upgradable

Highlighting / Features:

- 3D electronic nozzle positioning system

- Differential speed top/bottom roller • Variable speed seam sealing • Digital tensioning device • Multi-language support • Data memory • Ergonomic

SF-829 – Sewfree Tape Laydown + Ultrasonic Trimmer

- Stretch Fabric Ready • Precise Trimming

- Anti-fray Cut Edge • Perfect for Knit and Lyra

- Both Straight and Curve Seam • Software upgradable • Workable on 2D and 3D construction • 100 per cent Faster

Highlighting / Features:

- User Friendly Sewing Machine Platform • Extremely Narrow Allowance

- 28 KHz Quiet Operation • Differential Speed Top/ Bottom Roller • Colour Touch Screen Interface •Ergonomic

Wide range of high speed embroidery machines by Unix

Established in 2002, Unix Stitch Machines Pvt. Ltd. is one of the most innovative and creative companies emerging in computer embroidery industry. Within a short span of time the company has positioned itself as a pioneer technology supplier in the embroidery industry with a distinctive identity. Given are some of latest innovations:

High speed embroidery machine

18 heads, 9 colour, Max. speed 1350SPM, Emb. Area in 400x800x1300 Unix high speed embroidery machine productivity is achieved by ultra -precise control 1350 RPM in standard embroidery, which can meet various consumer demands for creation of high value added embroidery work. Sequin can be programmed into the design data or loaded manually via the control panel. Features:

- Indecent double can driving system for driving and pressure foot lifting, which guarantee the high speed machine to running at very high speed with perfect embroidering and quite working condition

- Latest semi auto oil system with separate oiling routes for upper head and lower rotary hooks system greatly extend the machine life

- Latest and advanced German technology for X.Y 12CM wide driver system, which can ensure 1200RPM running speed and perfect stitch at high speed as well as long life span

- RHP high and Jumbo bearing for guide rail trolley

- German brand Fulong belt for perfect stitches at high speed running conditions inside with glasses fibre instead of steel

- X,Y servo motor with 8cm wide belt pulley and belt which guarantee the high accuracy sewing work as well as life span

- Motorized jumper to support high speed running, and high speed jump stitch

- Latest Barudan standard quality tension base, with bearing type tension wheel ensure the thread feeding stability under high speed running as well as head life

- Extra enhanced heavy chassis for advanced bridge style machine body with H Beam support to resist vibration during high speed embroidering

- Enhanced pantograph aluminium material and SWF style pantograph side support

- New table mica, aluminium operation bar, stainless steel cover etc. for good machine finishing as well as quality

- Original Japan Hirose rotary hook sets, original Japan encoder, and original NSK key bearings for machine moving and transmission parts

- The more advanced high speed control system is designed and made with more accurate stitching and pantograph motion programming

UBS Series Semi High Speed Beading

- New DS Speedy Head: speedy, quiet & durable

- Beading Device: Workable on more sizes & shapes of glass beads

- Sync. Colour Change: Synchronized and assured smooth feeding of beads

- 8” OP Box: Cost effective but still powerful

- Motorized Trimming: Precise & steady

- Upper Thread Holding: Automatic & assured

- Dual Sequin Device: Quiet, precise cutting, universal sizes & shapes

- X-Y by Servo Motor: Fast precise motion

High speed laser embroidery machine

Equipped with laser system on the computer embroidery machine, which perfectly combines the technology of computer embroidery with laser cutting and the patterns fully realise the digital control. It saves abundant costs of plate making and knife mould production, eliminates the time cost and quality limitations of the traditional manual cutting, effectively reduces the production cost and improves the efficiency.

Suitable on various fabrics for special embroidery, applique, engraving, edgecutting, punching and stratified cutting, which can not only enrich the embroidery technology, but also improve the product quality and value addition. It makes the embroidery appeal more prominent with higher quality and stronger aesthetic feel. It creates a new era in the embroidery process and provides a new solution to garment, home textile and fabrics decoration industry.

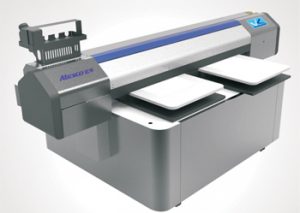

Richpeace presents latest embroidery and printing solution

Richpeace, a supplier of complete embroidery, quilting, garment and laser CAD/CAM software, hardware and mechanical and electrical integration equipment has released latest embroidery and printing Solutions.

Computerized multi-colour single roll quilting and embroidery machine

Not only can quilting, but also can embroidery, Four colours for more possibilities, Fabric can be used in roll continuously, Automatic Thread Trimmer, Japan Jumbo Rotary Hook, Can add function device, like embroidery machine, Unique lubricating system, 10.4 inches touch screen, More applications: Quilt, garment, curtain and seat cover, etc. Features:

• Single row with whole rollers, designed for bedding or other wide fabric quilting. Alternate head embroidery for large pattern • Automatic thread trimming to save labour for manual cutting • Four needles per head, for multiple colours • Unique lubricating system lubricates embroidery machine heads and hook parts, and prolongs life span of the machine • Equipped with Japan jumbo rotary hook, thread capacity is 2.2 times of standard bobbin, decreasing bobbin, replacement frequency and improving factory’s working efficiency • Richpeace professional embroidery CAD software with powerful function, easy to learn and user friendly.

Richpeace Digitizer

Richpeace Digitizer is a useful tool for all kinds of industrial data digitizer need, i.e. garment manufacturing, fashion design, map marketing, mining, punching and environment protection. It saves set up time with more than 30 popular software parameter pre-set inside the digitizer. User friendly, compatible to most popular graphic application, i.e. AutoCAD, Arcinfo, Micro station, Supermap, Lectra, open info, Arise, Billy, Cyber, GmCAD, Genamap, View IS MapEengin, ILWIS, SVCAD, DoCAD and Tajima Series, etc… furthermore, Gerber it supports workstations like SUN, SGI and others.

Richpeace Magic Inkjet Plotter

Main features & functions

• Stable and high speed printing, 140m2/hr maximum • The unique front & back paper – feeding structure and front feeding structure suitable for varieties of paper • Original Hewlett Packard HP45 ink cartridges, low cost and easy to replace • Servo motor system which improves the printing precision • Auto alarm when paper jam or run out

Richpeace Tubular Spreading Machine

• Use Mitsubishi PLC as control system, stable performance and easy maintenance • Touch screen colour display with English and Chinese bilingual for easy operation and learning • Spreading programmes control machine to perform efficient and tension free fabric distribution • Any spreading length can be performed • Intimate product design for easy operation and maintenance, high cost effectiveness.

Richpeace Flatbed Inkjet Cutter Plotter

Main features & Function

• Easy connection with USB • HP Inkjet print head technology, easy convenient to replace • Compatible with most popular brands of garment CAD software supports HPGL file format • Servo motor ensure high speed plotting and smooth working • Special table, smooth easy to cut, low cost • Hard knife suitable for different kinds of material • Auto paper seeding to support long marker

Turel Group to introduce ShangGong Group’s latest machines

Turel Group, a pioneer in bringing latest technologies to India, has now grown to become a solution provider to sectors such as: Garment, luggage, automobile, upholstery, home furnishing and heavy duty. Turel offers end to end solutions and consultation from the drawing board to selection of machines, ordering machinery, utilities with correct specification, installation, providing training to operators, trial run and handing over the project. Turel Group is connected wherever there is an application for needle and thread, or seamless covering all segments.

Turel has introduced many leading brands to India including Brother, Duerkopp Adler, Kansai Special, Kingtex, Naomoto, Typical, Vibemac and many more. Turel is constantly searching and bringing the best automation to India. The Group has now tied up with leading groups from China such as ‘ShangGong’ who are major shareholders of Duerkopp Adler, Pfaff, KSL.

In 2018, Turel Group is looking to introduce two new brands in India: Mauser Special Sewing Machines and DAMSH Automats.

• Mauser – Entry level sewing machine

• Mauser special – High quality operations

• Mauser industrial – For heavy duty and shoe operations.

• Damsh automats covering – for Shirt + Trousers segment

Viraf Turel, Managing Director, Turel Group says “With these variants, we are aiming to capture every segment of the market.” He explains the new brands to enter Turel’s stable will in not any way compete with the technologies the company already represents, as the market segments and price differentiation make the target group very different.

He says, the new association started during his meeting with Zhang Min, Chairman and CEO, ShangGong Group at the recent CISMA 2017 in Shanghai. “At CISMA, I came to know about brands DAMSH, Mauser Special. Their working and potential excited me, so I decided to bring these machines to India and represent them.”

The ShangGong Group has over the last few years taken over the responsibility of brands like KSL, Duerkopp Adler, PFAFF, SG Gemsy, Beisler and Mauser Special. While SG Gemsy and Mauser Special are Chinese brands, the rest are German. The company makes world-class machines in China at competitive prices. Turel feels the ‘Made in China’ label will not in anyway erode the value of Mauser Special.

Meant for both export and domestic markets, Mauser’s value will be augmented by the level of after sales service to be provided by the Turel Group. The company will train its technical team on the highly automated machines and gain knowledge about its working and specifications even before the machines reach India market. The installation and handing will be done by trained technicians. To further strengthen the support service for Mauser, ShangGong is planning to open a representative office in India. “I will give comprehensive support – pre-sales (an application engineer will train the operators about the machine), after sales, and after after-sales to help them get maximum out of the machine.”

Maya – high speed chain stitch & towel embroidery machine

Maya Electric Appliance Machinery Co., Ltd, with Yuanjing Mechanical & Electrical Co., Ltd, established in 2000 in Zhejiang Province, is a leading designer and manufacturer of “Maya” brand computerized embroidery machine, with annual sales volume over more than 4000 sets. The company supply a wide range of high-speed chain stitch & specialised mixed embroidery machines. These chain stitch & specialised mixed embroidery machine can also be provided as per customized requirements. Working on auto lift-up mechanism, these computerised machines facilitate automatic colour change and thread trimming function. Their range of high-speed chain stitch & specialised mixed embroidery machines provide optimum efficiency.

High speed chain stitch & towel embroidery

Main features and functions:

- Dahao Control

- Chenille embroidery will be softer and precise due to X-Y servo motors

- 10 different needle height for auto adjustment, chenille embroidery

- Towel embroidery, chain stitch embroidery can change colour automatically, with auto trimming, auto-thread break detection function

- Machinery structure, transmission structure is simple and accurate, reduces mechanical wear and tear easy to maintain

- A new generation of high speed chenille/chain/stitch embroidery head, long service life, easy maintenance, speed at 1200 RPM, low operating noise.

High precision vision cut system by Golden Laser India

Golden Laser India Pvt Ltd & Alliance Embroidery Services being regular participants at the annual event of GTE, New Delhi 2018. In quest of doing something exclusive every year this year also it is exhibiting its new product vision cut system for sublimation printed garments especially focussing on the sport wear industry and the printed lingerie industry. At present the sportswear industry is at a boom and the company wants its clients to explore all the machinery related options available, which can enable then to compete with other manufacturers all around the world and produce better quality so that Indian manufacturers enjoy the same position like other manufacturers from the US, UK & Central Asian countries. This year its exclusive display is the High precision vision cut system for sublimation garment industry.

Ramsons presents laundry, dry cleaning and garment finishing equipments

Ramsons is India’s largest manufacturer of commercial laundry, dry cleaning and garment finishing equipment. It has a proud Indian heritage, which gives it a single minded focus to provide the highest level of customer service. With some of India’s leading companies as its suppliers, strong engineering talent and stringent quality control systems, it manufactures high quality products that are exported globally.

Automatic Ironer for Knitwear – Knit-O-Matic

Features:

- Automatic Conveyor belt system for easy transfer of ironed knitwear to drying/ cooling and packing station

- Choice of PLC for complete function control or Manual control for adjusting Steam and vacuum timings.

- Automatic starting of functions through IR sensor

- User friendly PLC graphics for function monitoring or controls.

- Reliable and easy for maintenance.

- Flexibility for a wide variety of applications to iron any kind of knit wear

- Easy to operate for two operators which can iron two pieces at the same time.

- Constantly steaming of clothes makes the fabric softer than with a traditional iron.

- Two Lane Model-RKM2L can process 450 to 500 pieces per hour

Ramsons Vertostar (series 7.7) Vertostar auto sprinkler

Specially designed basket with heavy duty wedges for long life on denim pumice stone washing and external water barrier for automatic water sprinkling effect. Water sprinkler reduces the liquor ratio and improved wash effect. Hence great saving in water and better productivity. No additional pump and filter unit, Saves power and no need of regular cleaning filter unit. Easy maintenance of the external water barrier. It can be easily accessed from the top opening for inspection and maintenance. Standard features.

- Robust design outer with rigid basket mounted on heavy duty self-aligning ball bearings

- Epoxy coated bottom frame with powder coated guards & FRP side covers

- The machine is provided with PH testing port & sample port on main door, the sample door is provided with LED light to see the wash proces

- Hydraulically operated for tilting and easy unloading

- Dosing tank with control valve & SS pump for chemical dosing is controlled by PLC & also with manual

- 2 no’s of large drains for fast draining & also second drain can be used for water recycling

Special features:

De-stoner attachment: This series machines comes with optional de-stoning attachment. Fabricated with précised SS mesh fitted on and removed from the main door at the end of cycle. With this attachment, the pumice stones can be removed into a trolley, saving precious man hours.

Controlled Indirect heating & cooling system: The machine will have SS heat exchanger coil for both heating & cooling with pneumatic operated control valve. The heating gradient can be programmed through the PLC up to 6 degree per minute.

Inverter: Variable speed inverter drive with 6-40 rpm for washing & 80-100 rpm for pre-extraction The garments while unloading will not have much water, hence easier to handle and also the washing area will be dry and clean.

PLC: This machine has a microprocessor based programmer to control different cycles of the dyeing programmers like timing, temperature, dosing etc. The PLC can store up to 99 programmes with 100 steps in each programme.

Drive: The drive is through a geared motor for efficient and smooth. The belts used are Wedge belts of SPC section which has minimum slippage. The basket is fixed with a forged shaft mounted on heavy duty plumber block bearing of SKF make.

Ozonator Machine

This machine is all stainless steel with the inner drum diameter of 1500 mm and length of 1200 mm which gives an approx. value of 2120 ltrs.

- This machine has a perforated inner Basket and also full stainless steel outer drum with a large front opening with air tight door

- The air tight door has a view glass OM which a stainless steel nozzle is fitted for Ozone inlet

- The Basket is mounted on self-aligning bearings and the drive through reduction pulley system

- The machine has fully stainless steel pneumatically operated fresh air inlet valve, exhaust valve, stainless steel ducting, steam radiator and exhaust blower

- The machine has fully stainless steel pneumatically operated fresh air inlet valve, exhaust valve, stainless steel ducting, steam radiator and exhaust blower

- This machine also has a provision for fixing spray nozzle with dozing pump as an optional feature

Go Green

Conventional technologies seek the utilisation of huge amounts of water and chemicals during the process of fabric finishing. The quantity of discharge produced whilst this procedure is also high and harmful. Inspite of the ill-effects, these procedures have remained untouched since decades due to the lack of a reliable alternative. The latest innovation of Ramsons – Go Green Technology is a greener and earth-friendlier alternative for the fabric finishing and is undoubtedly an innovation for the future.

Fabcare presents latest garment dyeing solution

Established in 1995, Fabcare Garments & Textile Machinery Private Limited is one of the manufacturers and suppliers of garments & textile machinery in India. Its range is made as per the set industry norms and guidelines, utilising the finest raw materials and modern machines. This ensures the product’s performance, service line, strength and capacity. The offered range is made up of the finest textile machines, washer extractor and washing machine, which are widely demanded. In addition to this, the offered range is priced at the most reasonable rate possible.

Fabcare – Mist Spray – Resinator

Fabcare water free process for garment finishing is recently developed equipment, extending its use to all kind of surface treatments on garments. The main beneficiaries of the new technology are industrial laundries & garment dyeing house that will be able to carry out the application of softeners, dyes, antimicrobial products, among others, through a more eco-friendly, rapid and economic process.

It benefits finishing garment companies in both economic and environmental aspects. The use of the Mist Spray technology will derive in significant reduction of use of resources: Water use reduction up to 90 per cent, energy use reduction up to 47 per cent and eliminating chemical wastes associated to water dumping, all of them involved in garment finishing processes.

The equipment uses the exact quantity needed for the process; conditioning technology has been adapted to other specific textile finishing processes, like functionalization and exhaustion (Durable Water Repellence, Wrinkle-Free, 3D effects, CPD-Cold Pigment Dyeing.

- Technical aspects of the eco-innovative solution. The core technology consists of new equipment for treating garments. All processes are performed at room temperature with minimal quantities of water and chemicals.

- Conditioning processes: The simplest of finishing processes. Different kinds of softening applications can be performed through these processes.

- Functionalization processes: Specific treatments to give special properties to the garment such as resistance to make it waterproof, antimicrobial or anti-wrinkle and to give it UV protection. These treatments can be applied to protective clothing, sportswear or home textiles.

- Exhausting processes: Dyeing directly on garments. As production series are shorter than before, dyeing the garments directly is more common.

Water is precious – Let’s not waste it on Garment Dyeing

Today, garment-dyeing units have more options when it comes to both equipment and chemicals—the two main aspects of the business that were traditionally the least eco-friendly. Because of those increased options, and higher customer expectations when it comes to sustainability, what used to be an oddity is now essentially a requirement: According to some reports, 95 per cent of garment dyeing units are now looking for green products and services to appeal to customers.

When it comes to equipment, the big difference between traditional machines and eco-friendly options is in water and energy usage. There are now industrial garment dyeing machines that provide a superior quality while using up to 70 per cent less water and 50 per cent less energy than what the industry was used to, which is not only more sustainable, but more cost effective. Dyeing processes are also a big piece of the sustainability puzzle. Purchasing environmentally friendly chemicals isn’t enough; you have to be sure the chemical is being used in the proper amounts.

An overall solution

The moral of the story: Yes, garment-dyeing machines can be both effective and eco-friendly, but it isn’t enough to buy machines that claim to be green. We need to rethink the way we do dyeing-washing entirely. Fabcare Washers use up to 70 per cent less water, 50 per cent less energy, and approximately 50 per cent less chemicals enzyme, and delivers superior cleaning results compared to conventional washing machines. New Fabcare Splash washing machine is able to use less water and deliver a gentler wash, thanks to the revolutionary Splash technology, helping garment dyeing units to save on average almost a million liters of water each year.

Especially designed drum mechanically pressurized liquor to be penetrated into the garments. Said system provides 50 per cent more loading allowance along with 70 per cent saving from water, chemicals, heating energy, waste water, 40 per cent saving from electricity and 50 per cent saving from dye stuff. The result is higher quality, easier operation, more economic and competitive dyeing without any rejection even during the long process time. The Splash Series drum, as we named it, is a revolutionary drum structure with reverse scopes placed behind the beaters. This drum structure provides homogenous penetration of dyes-chemicals onto the fabrics, therefore increasing the effectiveness of washing quality.