India Awaits the Arrival of Homer’s Hybrid Digital Textile Printing Marvel with Up to 60,000 LM/Day Capacity

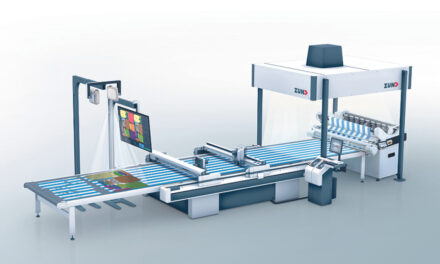

Orange O Tec has introduced ‘Rocket’, the hybrid single-pass digital textile printing machine to the Indian market. Engineered for unmatched speed, precision and environmental performance, Rocket is redefining the standards of digital textile printing capable of delivering speeds of up to 60,000 LM/day.

With support for pigment, reactive and disperse inks, Rocket is designed to serve the evolving needs of India, Bangladesh, and China’s dynamic textile industries. Its flexibility makes it the ideal solution for both bulk production and bespoke design driven applications.

Advanced Innovation: Hybrid Workflow Meets High Speed Output

The Rocket system is a fully integrated single-pass digital textile printer that automates the entire production flow from fabric feeding to final drying and collection-delivering high efficiency and minimal manual intervention.

Core Components Include:

• Fabric Feeding Unit

• Inline Coating

• Belt Guiding System

• Patented Online Fabric Sizing Station

• High-Speed Inkjet Printing Module

• Controlled Drying Chamber

• Smart Fabric Collection Unit

Versatile Fabric Applications & Ink Compatibility

Rocket provides exceptional print quality across a wide variety of textile substrates, thanks to its compatibility with multiple ink types. Its pigment ink capabilities, in particular, enable sustainable, water-free printing across:

• Natural fibres: Cotton, Viscose, Linen, Hemp

• Blended woven fabrics: Cotton-polyester, Viscose blends

• Synthetic textiles: Polyester-rich fabrics (with disperse ink)

Pigment Ink Advantage

As the textile industry moves toward greener practices, pigment ink stands out for its elimination of post-processing like steaming or washing. Rocket leverages this to significantly reduce water and energy consumption, while maintaining excellent durability, colour brilliance and light fastness-especially on natural fabrics.

Key Benefits of the Rocket System

No Plates, No Delays

Digital on-demand printing allows for instant setup, with no plate-making, unlimited repeat sizes, and intricate multi-colour designs.

True Hybrid Power

Rocket uniquely combines digital inkjet precision with rotary screen versatility and in line coating enabling a wide range of value-added effects, including:

• Metallic foils (gold/silver)

• Pearl and glue paste applications

• Colour-shifting inks

• Embossed and textured finishes

Patented Online Sizing Technology

Rocket’s integrated sizing station enhances efficiency by:

• Delivering up to 5000 metres per paste barrel

• Reducing paste consumption by up to 50%

• Cutting nitrogen emissions by nearly half

Ink Efficiency & Colour Brilliance

A wet-in-wet printing process allows for superior ink penetration and enhanced vibrancy:

• Up to 15% brighter colours

• 10–15% reduction in ink usage, lowering both costs and environmental impact

Market Impact Across Asia

China: Leading the Smart Factory Transformation

Rocket has already reshaped the production capabilities of Chinese textile giants. Shaoxing Shengxin Printing and Dyeing Co., Ltd. operates 6 Rocket units, printing over 3,00,000 square metres daily, enhancing product quality, reducing waste, and lowering labour dependency. To date, 25 Rocket machines have been installed in China, signalling strong market demand and alignment with the nation’s smart manufacturing initiatives.

Bangladesh: Driving Value-Added Export Growth

Rocket debuted in Bangladesh at the Dhaka International Textile & Garment Machinery Exhibition (DTG), catalyzing the country’s shift from bulk exports to customized, high-value manufacturing. With 9 machines already in pipeline, Rocket is helping Bangladeshi manufacturers elevate design capabilities, flexibility and export value.

India: Powering Surat, Tirupur & Emerging Textile Hubs

In India, Rocket is expected to arrive soon, and anticipation is already high in major textile hubs like Surat and Tirupur. The machine will support:

• Compliance with India’s ESG goals

• Rapid turnaround for short-run and customized orders

• Entry into premium global markets via high-end, sustainable printing

Rocket’s pigment ink support also positions it as a top choice for eco-conscious manufacturers aiming to reduce water use and eliminate post-processing.

Sustainable Engineering at Its Core

Sustainability is integral to Rocket’s design and engineering. Key features include:

• Low-temperature drying oven for reduced energy consumption

• Odour control and disinfection system for hygienic fabric output

• Streamlined system architecture to eliminate redundant machinery, saving space and operational costs

By minimizing post-processing and optimizing every stage of the workflow, Rocket drastically lowers both environmental impact and production overheads.

Final Word: A Platform for Future-Ready Printing

The Rocket hybrid single-pass digital textile printer is not just a machine – it’s a transformative solution for forward-thinking textile manufacturers. Whether you are printing natural fibres with pigment, blends with reactive, or synthetics with disperse, Rocket empowers your business with speed, flexibility and sustainability.