MIDORI APPAREL VIETNAM HOA BINH is a sewing factory for the MIDORI SAFETY GROUP in Vietnam, which manufactures and sells workwear mainly for Japanese companies. The company has installed several SHIMA SEIKI P-CAM automatic cutting machines for their accurate cutting performance. P-CAM has had no trouble such as breakdowns, and features good after-sales service. Therefore production can be carried out with confidence, even in areas where there are few craftsmen with cutting skills. P-CAM automatic cutting machine supports high-quality, stable mass production according to schedule.

MIDORI APPAREL VIETNAM HOA BINH is a sewing factory for the MIDORI SAFETY GROUP in Vietnam, which manufactures and sells workwear mainly for Japanese companies. The company has installed several SHIMA SEIKI P-CAM automatic cutting machines for their accurate cutting performance. P-CAM has had no trouble such as breakdowns, and features good after-sales service. Therefore production can be carried out with confidence, even in areas where there are few craftsmen with cutting skills. P-CAM automatic cutting machine supports high-quality, stable mass production according to schedule.

Norio Watanabe, General Director, Midori Apparel Vietnam Co., Ltd. said “We are the second sewing factory of the MIDORI SAFETY GROUP to open in Vietnam. We started operations in fall of 2013. Currently we have approximately 1,200 employees. This workforce produces about 1.8 million items per year. We manufacture various uniforms and workwear mainly for Japanese companies. We had installed SHIMA SEIKI machines at the first factory. Their performance, and the fact that there were no breakdowns or trouble with those machines, led us to install SHIMA SEIKI machines here at the second factory as well.

As you can expect there are many difficulties when starting a factory in a foreign country. Especially for this second factory, it is located in a rural area. Because there was not much industry, we could not expect to hire experienced craftsmen with cutting skills. In order to ensure accurate cutting, we decided from the very beginning to install automatic cutting machines.

When we opened our first factory in Vietnam, we stated with one automatic cutting machine. With steady increase in production numbers, 3 units are now operating at the first factory and 4 units are in operation at the second factory. We plan to expand our facilities even further in order to handle more orders, so we are considering installing more units in the future he added.

Takashi Kuraoka, Director of Factory said “The biggest benefit is that after-sales service is very good. If by chance we have any trouble, we can expect an immediate response. Next is cutting accuracy and fewer breakdowns. By cutting every layer of fabric precisely from top to bottom, sewing can be performed in the same manner for each piece, every time. Stable quality is one of the most important requirements in mass-production.

P-CAM machines feature a highly sophisticated cutting mechanism with a reciprocating knife for precision cutting through fabrics up to 3 inches in thickness. P-CAM also features a special function to cool the blade while cutting material that can melt and adhere to the blade. An improved knife sharpening system also permits more precise cutting.

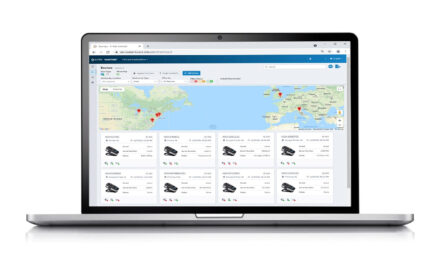

In addition to the apparel industry, SHIMA SEIKI’s CAD system and computerized cutting machines cater to a variety of industries, supporting all our customers’ needs.