Pressing and Creasing Machines by EPA AKIN

Since 1989 EPA AKIN brand provides excellent service and state-of-the-art machinery to the world’s most renowed leaders of shirt manufacturing. EPA has all kinds of shirt machinery solutions from begging to end of shirt manufacturing process. EPA AKIN currently exports textile machinery to 50 countries. Every year EPA AKIN brand try to improve machines techniqually. EPA AKIN brand provides solutions to shirt manufacturers in all over the world with all kinds of shirt presses.

Since 1989 EPA AKIN brand provides excellent service and state-of-the-art machinery to the world’s most renowed leaders of shirt manufacturing. EPA has all kinds of shirt machinery solutions from begging to end of shirt manufacturing process. EPA AKIN currently exports textile machinery to 50 countries. Every year EPA AKIN brand try to improve machines techniqually. EPA AKIN brand provides solutions to shirt manufacturers in all over the world with all kinds of shirt presses.

EPA 205 – Shirt Front Placket Pressing and Creasing Machine

Machine Features

• Perfect shirt front pressing, from 15mm to 75mm

• Shirt Front Placket Pressing and Creasing Machine can make short sleeve foldings

• Able to produce separated front strips for shirts or blouses

• Capable of fusing the interlining during the folding process

• Specially designed ironing table and pressing system of Shirt Front Placket Pressing and Creasing Machine provide high-quality ironing and interlining

• Laser-guided ironing processes of striped fabrics

• Oil-free operation system

• High vacuum motor is installed inside the Shirt Front Placket Pressing and Creasing Machine

• Easy to use digital display

• Digital screen provides hourly and daily production reports

• Smart-fault notification system of Shirt Front Placket Pressing and Creasing Machine enables easy detection of machinery malfunctions, trackable using the screen

• Automatic stacking system

• Unique resistors and computerized temperature control system of Shirt Front Placket Pressing and Creasing Machine provides precise heat adjustment and energy savings

• Interlining interlacing device reduces the interlacing to a minimum level (optional)

• PLC (Programmable Logic Control) controlled machine

• A number of safety precautions protect the operator

• Shirt Front Placket Pressing and Creasing Machine has a CE certificate

EPA 203- Sleeve Placket Creasing Machine

Machine Features

• Sleeve Placket Creasing Machine presses sleeve plackets, bindings, and shirt side seams in desired sizes

• Our Sleeve Placket Creasing Machine is capable of pressing triangle and square labels, plus yoke labels

• Adjustable trace needles speed up and standardize production during assembly stage

• Seam allowances can be set as desired

• Sleeve Placket Creasing Machine features an Oil-free operation system

• Easy to use digital display

• Digital screen provides hourly and daily production reports

• Smart- fault notification system of Sleeve Placket Creasing Machine enables easy detection of machinery malfunctions, trackable using the screen

•Laser attachment provides easy stripe tracing, leading to excellent results during pressing of striped fabrics

• Automatic stacking system

• Unique resistances and computerized temperature control system of Sleeve Placket Creasing Machine provides precise heat adjustment and energy savings

Brother’s Sewing and Bonding Machines

Brother is a renowned Japanese company whose corporate profile includes a wide range of electronic, industrial and household appliances. Since its foundation, Brother has established itself as a leading manufacturer of industrial sewing machines, printers and multifunctional devices. With sales offices worldwide, Brother has a global presence and offers first-class products and services in various markets. Brother’s industrial sewing machine division benefits from over 100 years of experience and is a major sales driver for the company.

Brother is a renowned Japanese company whose corporate profile includes a wide range of electronic, industrial and household appliances. Since its foundation, Brother has established itself as a leading manufacturer of industrial sewing machines, printers and multifunctional devices. With sales offices worldwide, Brother has a global presence and offers first-class products and services in various markets. Brother’s industrial sewing machine division benefits from over 100 years of experience and is a major sales driver for the company.

Bonding BM-2000

The Brother BM-2000 bonding machine is an outstanding example of innovative technology in the field of textile processing. Designed for maximum precision and efficiency, this machine enables seamless and reliable bonding of fabrics without the need for seams. Utilising advanced bonding techniques, the BM-2000 provides a consistent and durable bond that meets the requirements of a wide range of applications. With its user-friendly design and reliable performance, the Brother BM- 2000 is the ideal choice for companies looking for high quality and durable solutions for their production processes.

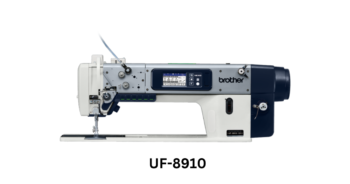

UF-8910 Single Needle Direct Dirve

UF-8910 Single Needle Direct Dirve

The Brother Unison Feed UF-8910 is a state-of-theart industrial sewing machine designed for precise and reliable sewing in industrial environments. With its innovative Unison Feed technology, this machine offers outstanding fabric feeding that ensures consistent sewing even with challenging materials such as leather, vinyl or multiple layers of fabric. The UF-8910 is equipped with a variety of features, including a powerful motor, a user-friendly interface and a high sewing speed that enable efficient production. The robust construction and high-quality materials ensure a long service life and minimise downtime.

BAS-342JX Direct Drive Programmable Electronic Pattern Sewer with Cylinder Bed

BAS-342JX Direct Drive Programmable Electronic Pattern Sewer with Cylinder Bed

The Brother BAS-342JX is a advanced industrial sewing machine designed for precision and efficiency in textile production. The machine is equipped with a user-friendly touch screen panel that allows for easy programming and operation. This allows users to quickly and efficiently switch between different sewing tasks and customise the machine to specific requirements. In addition, the BAS-342JX offers high sewing speed and outstanding stitch quality, making it ideal for the production of garments, home textiles and other textile products.

Sewing System for Pocket Openings by A-S-S AG

To develope and build high quality and efficient sewing systems in Germany: with this requirement we founded the A-S-S AG in the year 2000. Previously we had been working for more than 25 years with renowned manufacturers of our industry. These experiences have linked with fresh ideas, which consistently meet customer requirements and create innovative solutions. So our company could constantly grow. Today, among others, seam-closing and pocket welting machines as well as engineered workstations are to find in our portfolio. The sales figures have passed meanwhile over 6,000 machines.

To develope and build high quality and efficient sewing systems in Germany: with this requirement we founded the A-S-S AG in the year 2000. Previously we had been working for more than 25 years with renowned manufacturers of our industry. These experiences have linked with fresh ideas, which consistently meet customer requirements and create innovative solutions. So our company could constantly grow. Today, among others, seam-closing and pocket welting machines as well as engineered workstations are to find in our portfolio. The sales figures have passed meanwhile over 6,000 machines.

BASS – 3050 (Sewing System for Pocket Openings

The BASS 3050 is a universal automatic welt pocket sewing machine. The machine processes all prevalent pocket openings with and without flaps.

The BASS 3050 is impressive with its high operating speed. The clamp transport and all cutter systems of the sewing machine have their own separate drive. The clamp transport is controlled fully automatically by a stepper motor and the centre cutter is driven by a separate electric motor.

Advantages

• Simple operation

• Quick learning process

• Quick changeover from double welting to single welting

• Customised setting for stitching and transport speed

• Automatic sensing of flap length

• Independent drives for clamp transport as well as all cutting systems

• Easily programmable

• Needle distances can be retrofitted from 8 mm–24 mm, in steps of 2 mm

• Cutter adjustment for corner cutter position in steps of 0.1 mm

BASS – 3204 (Sewing System for Pocket Openings)

BASS – 3204 (Sewing System for Pocket Openings)

The BASS 3204 is a universal automatic welted pocket sewing machine. The sewing machine processes all prevalent pocket openings with and without flaps. The incorporation of a zipper can be integrated easily into the sewing operation. Even welted breast pockets can be incorporated with the appropriate options. Simple operation and high working speed characterise this universal automatic welted pocket machine.

Advantages

• Quick learning process

• Numerous options for special applications

• Quick changeover from double piping to single piping

• Freely programmable controller with memory for 40 seams

• Customised setting for stitching and transport speed

• Customised programming possible for stitch length, seam locking or adjustable stitch length

• Independent drives for clamp transport as well as all cutter systems

• Pocket opening lengths from 20-200 (optional 240 mm)

• Easily programmable

• Needle distances can be retrofitted from 8 mm–24 mm, in steps of 2 mm

• Cutter adjustment for corner cutter position in steps of 0.1 mm

• Automatic clamp adjustment when folder is changed

• Automatic seam length adjustment

Automatic Embroidery Machines by Barudan Co. Ltd.

BARUDAN Co., Ltd. is the manufacturer of Japan made computerized embroidery machine in Japan. Since 1959, Barudan has been producing the best built, the most reliable embroidery machines in the world and proudly produced in Japan. We have exported BARUDAN embroidery machines to over 100 countries throughout the world with the corporation of BARUDAN Global Network.We have subsidiaries in 9 countries, Japan, France, USA, Canada, Singapore, Turkey, UK, China and Brazil.

BARUDAN Co., Ltd. is the manufacturer of Japan made computerized embroidery machine in Japan. Since 1959, Barudan has been producing the best built, the most reliable embroidery machines in the world and proudly produced in Japan. We have exported BARUDAN embroidery machines to over 100 countries throughout the world with the corporation of BARUDAN Global Network.We have subsidiaries in 9 countries, Japan, France, USA, Canada, Singapore, Turkey, UK, China and Brazil.

Automatic Embroidery Machine (BEKY-S1506CII)

• High Spec Drop Table Machine with Servo Motor

• The perfect machine for any size order

• Compact, Fast & Reliable

• New trimming system with a narrow cylinder arm: New trimming system with a narrow cylinder arm allows more room to embroider shirt pockets, socks and smaller items

• New thread tensioning system: New thread tensioning system ensures better tensioning and faster threading

• Touch screen (10.4 inch, Resolution 800×600)

• Ability to register shortcuts into multiple groups

• Customizeable Display

• Easy Icon based operation

• LAN Connector Standard, 1×COM Port & 1×USB Port, 1×Remote Controller Connector

• 70 million stitch capacity, 100 memory locations

Automatic Embroidery Machine (BEKT-S1501CAII)

• New KT LCD 8.4 inch color touch screen display is larger, providing improved visibility and easier operation

• Servo motors deliver fast and smooth pantograph operation for increased production and pinpoint accuracy

• New thread tensioning system: New thread tensioning system ensures better tensioning and faster threading

• Name Drop: Separates names in a multiple name design for view and sewing purposes.

• Frame Centering Function

• Frame Limit Function: Able to restrict machine operation when a design does not fit to the frame or when here is a risk of a needle bar hitting the frame

• Shortcuts: Customize most-used icons to save time

• LAN Connector Standard, 1 USB port

• 70 million stitch capacity, 100 memory locations

Fully Automatic Fabric Spreading and Seam Bottom Hemming machines by ASTAS

Company ASTAS with its headquarter in Istanbul and further 12 branch offices in Turkey and abroad is a specialist in sewing technology and an acknowledged partner for the leading garment industry and trade brands for more than 40 years. Our vision is to serve maximum support for the worldwide competitiveness of the garment and apparel sector, to supply the most innovative solutions to increasing workshops and thus help the sector heading for high value-added items. In addition, adapting the latest technology equipment to the existing machinery park, in order to provide the best service to achieve the energy economization and time management and high quality and highest efficiency.

Company ASTAS with its headquarter in Istanbul and further 12 branch offices in Turkey and abroad is a specialist in sewing technology and an acknowledged partner for the leading garment industry and trade brands for more than 40 years. Our vision is to serve maximum support for the worldwide competitiveness of the garment and apparel sector, to supply the most innovative solutions to increasing workshops and thus help the sector heading for high value-added items. In addition, adapting the latest technology equipment to the existing machinery park, in order to provide the best service to achieve the energy economization and time management and high quality and highest efficiency.

ASTAS self-made workstations offer intelligent solutions for the garment industry with automatic sewing machines and sewing stations simplify sewing processes and thus also increase productivity. We supply our workstations, which are custom-made, to the textile and garment industry, to the automotive and mattress industry, to companies with technical textiles.

Fully Automatic Fabric Spreading Machine – SRM 255 XXL SERIES

• Denim/Jeans – assembled for spreading the large type weaving fabric

• Preferable language; Turkish or English

• Remote connection (option)

• Via intensive sensor, the ability to spread the beginning of the fabric in each ply in some line automatic (gain fabric)

• Ability to interfere with the software and spread at fully automatic mode

• Auto-Stop feature when the roll runs out or pre recorded number of folds is achieved

• Ability to unroll or rewind (for Roll Fed Fabrics)

• Ability to enter different speed choices, in order to save time during idle turns

• One way or zig-zag spreading features (zig-zag is optional)

• Spreader system which ascends automatically, in accordance with spreading height

• Backwards opening cradle and loading extension, enabling easy fabric loading

• Maximum operation comfort, by means of its operator carrier platform

• True-sense safe operation, ensured by privileged safety sensors

• User-friendly Touch Screen pane

AST-7923/ERDO-KR/M-PLC-2/SM-BDN

Top Covering Type, Cover Seam Bottom Hemming Automat with Step Motor Controlled Special Automatic Size Adjustment Device with Sensor

• Hemming adjustment attachment system between 17-30 mm.

• Able to work 40-80cm tubular shirt bottom hem

• Stitching starts and ends at the side seam

• Stitch alignment feature thanks to sensor-controlled system

• Thanks to the size tolerance system, the machine can adapt itself for measurement differences up to 1 cm for the same sizes

• Step motor controlled size adjustment feature – SM-BDN

• Hemming correction feature by means of roller system at the start of seam

• One operator can run 2 machines

• Excellent 3 needle Top Covering Type or 2 needle cover seam stitch quality

• LCD touchscreen control unit

• Daily piece counter

• Thread breaking sensor

• Automatic stacker unit

• Up to %40 energy-saving thanks to direct drive Efka servo motor technology

• Capacity 2.400-3.000 pcs/ 8 hours

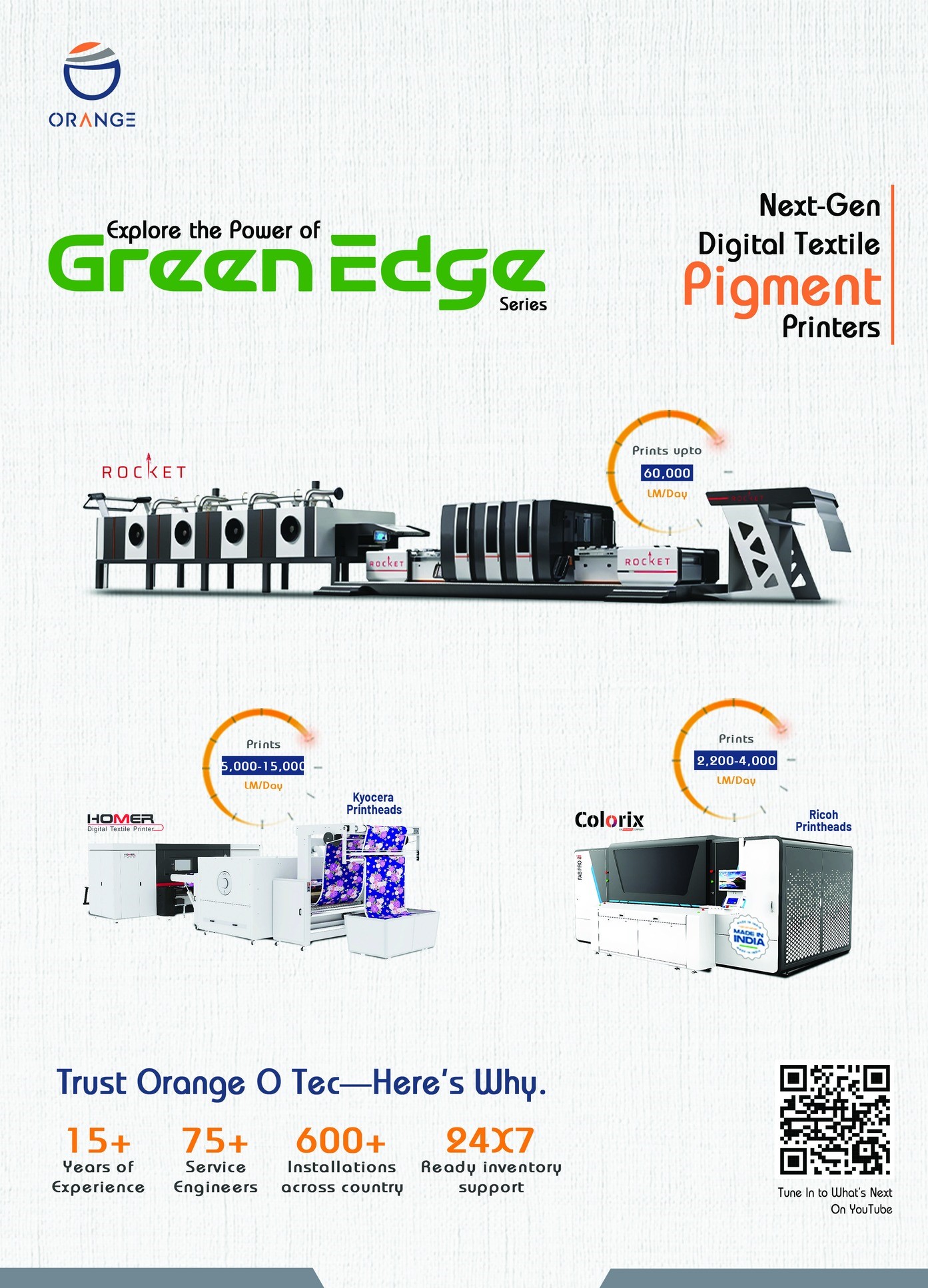

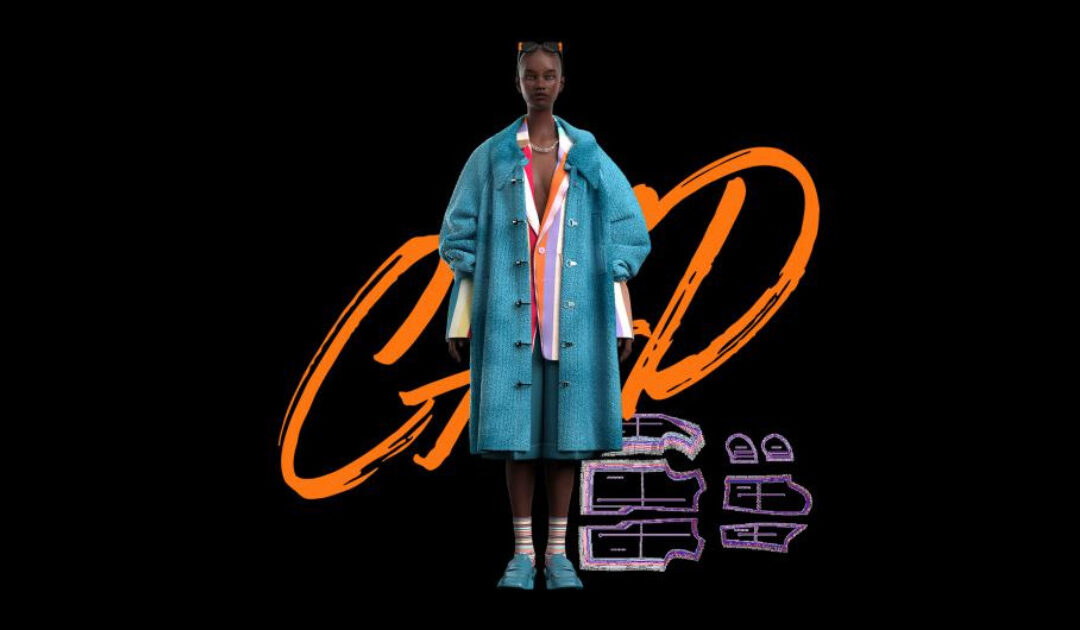

Assyst.CAD: 2D Pattern Making Software by Assyst

Style3D | Assyst enables brands, manufacturers, and retailers to create and produce successful fashion products, and to promote them directly on all sales or marketing platforms.With our innovative technologies, we are pioneers in transforming the clothing industry towards a fully digital, sustainable, and profitable future. Our team includes over 600 experts in fashion and technology across 15 locations worldwide. We distribute our software and solutions for 3D design, fabric simulation, 2D pattern development, nesting, costing, 3D asset & collaboration management, as well as retail in more than 60 countries.Through research and development in collaboration with leading universities, we ensure our development lead. Style3D and Assyst are represented in Europe by Assyst GmbH, operating under the brand name Style3D | Assyst.

Style3D | Assyst enables brands, manufacturers, and retailers to create and produce successful fashion products, and to promote them directly on all sales or marketing platforms.With our innovative technologies, we are pioneers in transforming the clothing industry towards a fully digital, sustainable, and profitable future. Our team includes over 600 experts in fashion and technology across 15 locations worldwide. We distribute our software and solutions for 3D design, fabric simulation, 2D pattern development, nesting, costing, 3D asset & collaboration management, as well as retail in more than 60 countries.Through research and development in collaboration with leading universities, we ensure our development lead. Style3D and Assyst are represented in Europe by Assyst GmbH, operating under the brand name Style3D | Assyst.

Assyst.CAD: 2D Pattern Making Software

With Assyst’s leading pattern making software Assyst.CAD, you can make patterns and gradings for your fashion products fast and effectively.

• Make patterns and gradings: Fashion professionals simply love the sophisticated fit, grading and intuitive Smart technology that makes Assyst.CAD (CAD.Assyst) the leading fashion pattern making system in Germany, Austria, and Switzerland.

• Managing and re-combining pieces: The Assyst.CAD database with modular logic flexibly manages 2D patterns and 3D simulations. This creates transparency and facilitates version control and teamwork.

• Automate pattern design tasks: Smart.Pattern macros efficiently perform tedious tasks, saving valuable time and reducing errors. With a library of over 200 routine macros, you can easily streamline your workflow. To get you started, 10 macros are included free of charge.

Assyst.CAD is integrated throughout the development process

Only with Assyst, are 3D, CAD, pattern making, and order planning directly connected. As a result, data from Assyst.CAD (Cad.Assyst) is available throughout the entire fashion development process, from 3D design to production

• Work in 3D with a fully developed 2D pattern from Assyst.CAD ready for production

• Specific grading data: Intuitively, visually, and quickly generate grading for a complete size range – including individual grading rules for your brand.

• Create markers manually or automatically directly from Assyst.CAD (Cad.Assyst) with direct specifications from the pattern

• Collaborate globally: With Assyst’s Fashion Cloud, you can ensure access to all CAD and 3D data. Hosted in a European high-security data center in accordance with ISO/IEC 27001

Special benefit – connectivity through data conversion Assyst is open to third-party systems

• A mixed cutter or plotter landscape, greater flexibility in support, or the introduction of 3D and automation are common reasons for switching to Assyst.CAD

• With Assyst, you can connect your systems to each other. When transferring to Assyst.CAD, we ensure that you can continue to use your cutting data – no matter which system it comes from

• Assyst supports most of the common formats in the market with high quality. If necessary, the system can reconstruct the entire pattern. Our expert team actively supports you in your conversion project