Orange O Tec introduces PHOENIX K-64: The Game-Changing Digital Textile Printing Machine

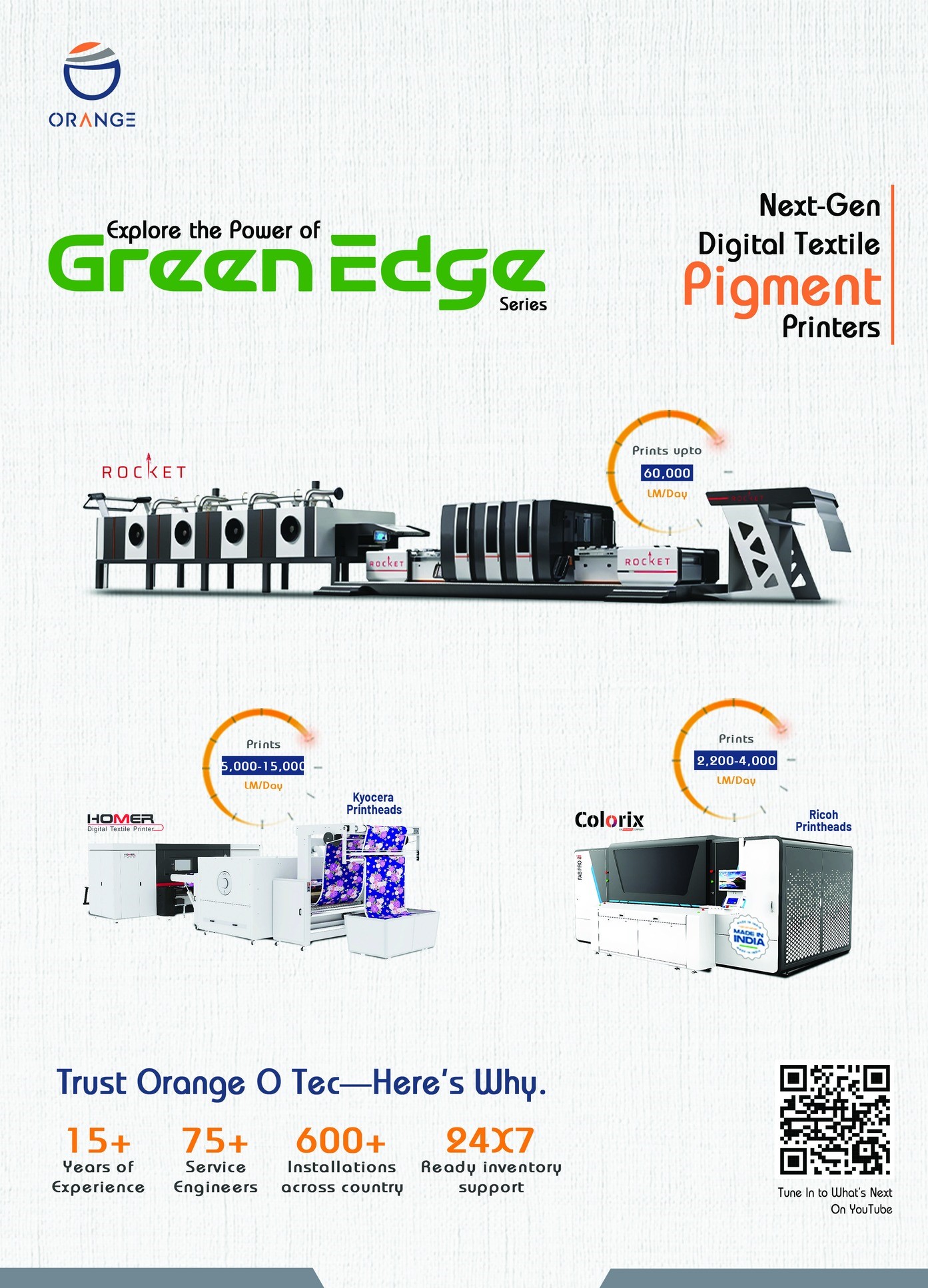

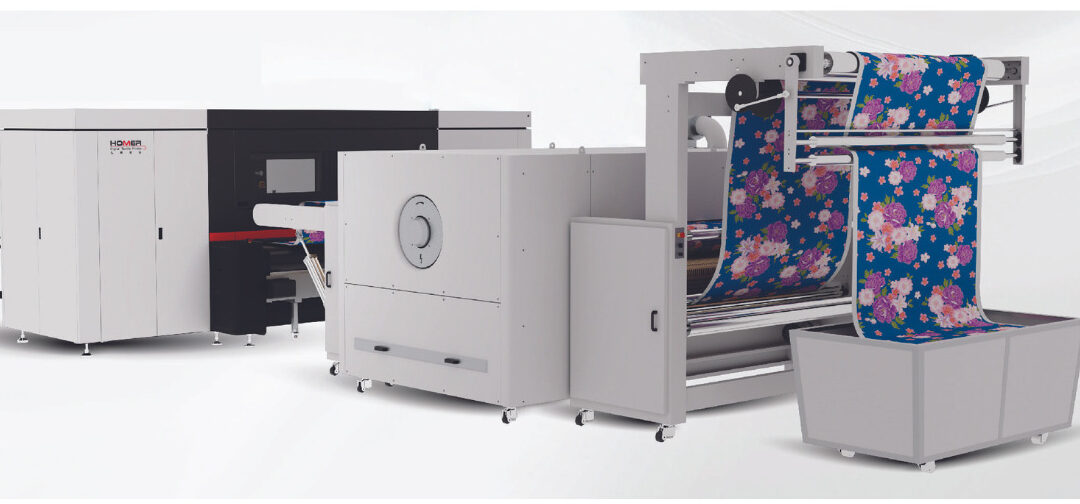

Orange O Tec, a pioneering company in the digital textile printing industry in India, proudly unveils its latest innovation: the Phoenix K-64 digital textile printing machine. Designed to revolutionise the textile printing landscape, the Phoenix K-64 boasts 64 heads by the renowned company Homer, offering unparalleled speed, precision, and efficiency.

Orange O Tec, a pioneering company in the digital textile printing industry in India, proudly unveils its latest innovation: the Phoenix K-64 digital textile printing machine. Designed to revolutionise the textile printing landscape, the Phoenix K-64 boasts 64 heads by the renowned company Homer, offering unparalleled speed, precision, and efficiency.

With a production capacity of up to 15,000 meters per day, the Phoenix K 64 emerges as the fastest machine in India, setting new benchmarks for productivity and performance. Its cutting-edge technology ensures precise printing, delivering superior results with every run. It is the one of the fastest scanning machine in this range.

In all the senses, Phoenix K-64 is an ideal solution for replacement of conventionalflat bed production, as it is much faster and more efficient. The machine as already arrived in major locations of the North and West regions of India. Considering its advantages, the textile printers are showing keen interest in adopting this new revolution.

Orange O Tec, based in Surat, Gujarat, has established itself as a formidable player in the digital textile printing industry, capturing over 35% of the market share. With a mission to democratise the textile industry, Orange O Tec empowers creative minds with limited capital resources to establish their printing setups. Unlike traditional methods that demand substantial investments in infrastructure, Orange O Tec’s digital printing machines offer cost-effective and flexible solutions, enabling even small business owners to realize their creative visions.

In a strategic partnership with Homer Group, a comprehensive industrial digital printing solution provider, Orange O Tec enhances its offerings with access to cutting-edge technology and expert support. Homer specialises in digital inkjet printing technology, providing end-to-end solutions for various industries, including advertising, home improvement, clothing, textiles, packaging, and more. With a portfolio encompassing digital inkjet printing equipment, software, ink, accessories, and professional services, Homer ensures that customers receive high-quality printing solutions tailored to their specific needs.

” The launch of the Phoenix K-64 marks a new era of innovation and efficiency in our industry, empowering businesses of all sizes to unleash their creativity and achieve unparalleled success,” said Aayush Rathi, Director Orange O Tec, adding ” Our collaboration with Homer represents a significant milestone in our journey to redefine the digital textile printing landscape.”

As the demand for digital textile printing continues to soar, the Phoenix K 64 emerges as a game-changer, offering unmatched speed, precision, and reliability. With its exceptional performance and strategic partnership with Homer, Orange O Tec reaffirms its commitment to driving innovation and transformation in the textile printing industry.

Flatseamer and Bottom Hemming machines by Yamato

Yamato Sewing Machine Mfg. Co., Ltd. is technology-oriented industrial sewing machine manufacturer, based in Osaka, Japan since 1927. Our main products are “YAMATO” brand industrial sewing machines, such as overlock, interlock chain stitch, flatseamer, as well as various devices and attachments. Beyond just manufacturing industrial sewing machines, Yamato strive to provide our customers with practical solutions to various sewing-related problems. The solutions we provide are backed by our advanced technology and know-hows accumurated by co-works with our customers throughout our long history.

Yamato Sewing Machine Mfg. Co., Ltd. is technology-oriented industrial sewing machine manufacturer, based in Osaka, Japan since 1927. Our main products are “YAMATO” brand industrial sewing machines, such as overlock, interlock chain stitch, flatseamer, as well as various devices and attachments. Beyond just manufacturing industrial sewing machines, Yamato strive to provide our customers with practical solutions to various sewing-related problems. The solutions we provide are backed by our advanced technology and know-hows accumurated by co-works with our customers throughout our long history.

Yamato’s practical solutions to various challenges in manufacturing athletic/athleisure wear, casual wear and lingerie, backed by our advanced technology, such as extra stretch seam, which adds extra value on your functional garments, deskilled operation for uniform high-quality finish without relying on skilled operators, and even possibility to skip operation.

FD-62SD-LF Series (4 Needle 6 Thread, Feedoff-the-arm “Loss-Free” Flatseamer)

The Flatseamer for stretch materials that reduces defects and achieves extra stretch, outstanding apperance, comfort & functionality

Extra Stretch, Without the Risk for Breakage: With the new design that securely tightens the needle thread at low tension, the seam stretchability is improved by 30%. This significant reduction in needle thread half catch and seam jams ensures high-quality seams required in premium products.

Innovative New Technology for the Perfect Seam: FD-62SD-LF’s innovative technology makes it possible to create flat and wide enough seams without the risk of damaging fabric by retainer needle.

Contribute to Cost Reduction: FD-62SD-LF helps customers improve profitability. FD-62SD-LF is equipped with advanced technologies that reduce quality and time waste. It meets advanced sewing needs without the need for complicated adjustments and reduces the risk of seam breaks, needle holes, and oil stains.

EZH-B-VGS3721-156S1-8F/UTQ-A45/Y (SemiAutomatic EZ (easy) Bottom Hemming Workstation for Circular Material)

Semi-Automatic Easy Bottom Hemming Workstation for Circular Material which deskills circular hemming operations drastically. Required jobs to operators are reduced to loading the work, overlapping and unloading only. The rest is done by this workstation. In addition, this configuration equips UTQ, the unique & advanced Automatic under Thread Trimmer with Anti-Unraveling Device. UTQ enables you to eliminate tacking process, making better looking and comfort to wear.

• Drastically deskills Circular hemming, one of the most critical operations on knitwear assembly. EZHB plays the role of the right hand of the expert operator. EZH-B makes the hem, maintain the hem and control the edge of fabrics. Required jobs to operators are reduced to loading the work, overlapping and unloading only. The rest is done by this workstation.

• EZH-B reliably feeds fabrics in a relaxed condition, thanks to the top feeder and Yamato’s unique Active Thread Control technology. Therefore, iron-free perfect finish can be obtained, without roping, twisting or puckering.

• Yamato’s signature Active Thread Control supports ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears.

• Yamato “Non-stain” Technology for minimizing the risk of oil stain, the most frequent cause of defects.

• UTQ enables you to eliminate tacking process thanks to the unique anti-unraveling technology to avoid seam unravelling from the end.

Summa releases New Software: GoProduce Flatbed Edition 3.0

Summa nv, a leading company of high-end cutting plotters and finishing systems, has released a new version of their GoProduce software, GoProduce Flatbed Edition 3.0. This software is explicitly tailored to Summa’s flatbed cutter range, the F Series. As a result, the in-house developed software ensures optimal utilisation of the flatbed cutters and efficiency in customers’ production processes.

Summa nv, a leading company of high-end cutting plotters and finishing systems, has released a new version of their GoProduce software, GoProduce Flatbed Edition 3.0. This software is explicitly tailored to Summa’s flatbed cutter range, the F Series. As a result, the in-house developed software ensures optimal utilisation of the flatbed cutters and efficiency in customers’ production processes.

GoProduce Flatbed Edition

GoProduce was originally released in 2019, as the first software module within Summa’s GoSuite platform. This was followed by a major upgrade to version 2.0 in 2020. Summa always strives to deliver innovative and cutting-edge solutions, so the major upgrade was done to stay up-to-date with the latest technologies. Out of the same aspiration, GoProduce Flatbed Edition 3.0 is born. The specification ‘Flatbed Edition’ has now been added to the software name to make a clear distinction in the software available, as Summa also has production software for their L Series laser cutters called GoProduce Laser Edition.

The software comes with every new F Series and is easy to install. With its intuitive interface and easy navigation, the software is user-friendly and users quickly find their way around. For users who want to get the most out of their cutter and workflow, a Pro Pack is available that unlocks additional features such as Barcode functionality, Hot folder support and Twin X workflow.

General great things about GoProduce:

• Material manager: Library of materials and their optimised settings. There are already a whole lot of them included but you can also add new ones manually.

• Action sets: there are standard action sets or you can custom make them, perfect to optimise the workflow for your way of working.

• Backside cutting: it’s possible to cut the unprinted backside of the material, perfect for cutting packages, as that way the tool does not damage the design.

• Sorting: Optimises the cutting path, making the machine more efficient and makes your output faster.

• Barcode functionality Pro Pack: The barcode functionality reads the printed barcode and automatically identifies the job to obtain the necessary cutting data from the computer.

More Powerful, More Connected, More Enhanced

The new GoProduce Flatbed Edition 3.0 is now available, and it has some great new features:

• Powerful 64-bit software: Not only does the software run faster, but there is now more working memory, making it operate more efficiently.

• Connected media handling: It integrates the flatbed cutter smoothly with peripherals to create an efficient automated workflow, using our GoConnect software integration.

• New predefined action sets for automatic feeder support.

• New logging features for better support.

The V3 software is optimised for routing jobs. It comes with new routing capabilities that are perfect for cutting out shapes more precisely. They maximise productivity when processing wood, acrylics, and plastics. The features supporting this are:

• Automatic detection of drill hole placeholders.

• Lead-in or lead-out for the milling path: It can now automatically start and end outside of the shape. There are two possibilities to do this using either a perpendicular lead-in or corner lead-in.

Empower Your Machine Precision

Randi Kerkaert, Product Manager at Summa, reflects on the importance of the upgrade for our customers: “I’m excited to see how this major software release will take our customers’ production processes to the next level. We’re not just updating features; each major upgrade enhances the way our users interact with their F Series flatbed cutters and helps to maximise the productivity of their equipment. With GoProduce Flatbed Edition 3.0, we’re once again raising the bar for what users can achieve with our software.”

The GoProduce Flatbed Edition 3.0 software is available with every new F Series and as a paid upgrade for existing users.

Kornit Digital set to demonstrate the unmatched power of Single-Step Digital Fabric Printing at Texprocess 2024

Kornit Digital LTD., a worldwide market leader in sustainable, on-demand digital fashionx and textile production technologies, announced today the company is setting the stage for an unprecedented display of its vibrant digital fabric and integrated workflow portfolio at Texprocess 2024. Kornit’s display at Messe Frankfurt – being held April 23-26 – allows attendees to experience the unmatched power of digital textiles, enabling companies to grow both dynamically and sustainably, respond to ever-changing customer demands and embrace the newly digital supply chain. Don’t miss the chance to visit Kornit Digital at Hall 8, Stand A32.

Kornit Digital LTD., a worldwide market leader in sustainable, on-demand digital fashionx and textile production technologies, announced today the company is setting the stage for an unprecedented display of its vibrant digital fabric and integrated workflow portfolio at Texprocess 2024. Kornit’s display at Messe Frankfurt – being held April 23-26 – allows attendees to experience the unmatched power of digital textiles, enabling companies to grow both dynamically and sustainably, respond to ever-changing customer demands and embrace the newly digital supply chain. Don’t miss the chance to visit Kornit Digital at Hall 8, Stand A32.

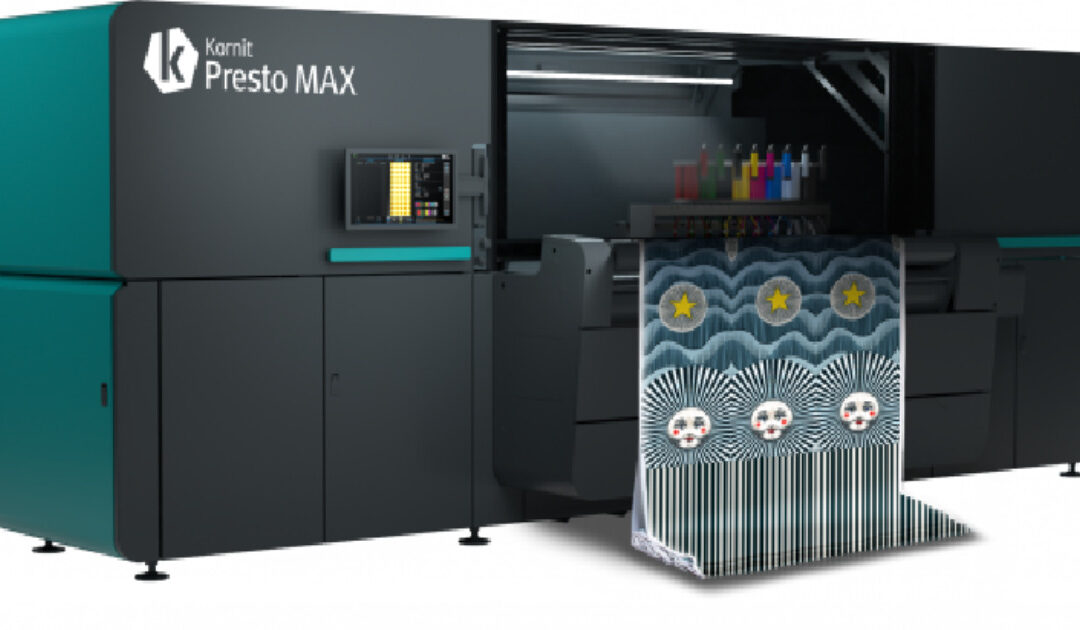

Kornit Digital will feature a view into the end-to-end, fabric manufacturing ecosystem – allowing for production of any fabric and any design for any purpose. The centerpiece is Kornit Presto MAX, rapidly transforming the digital world of fabric printing with an ability to print on any fabric type – from cotton and polyester to denim and leather. This single-step solution sets new benchmarks in both textile design and manufacturing across fabrics, home décor, and more. Built on the promise of sustainability, Presto MAX is proven to dramatically reduce both water usage and waste – ensuring businesses can thrive in an eco-conscious marketplace. The system is the world’s first offering to print white ink on colored fabrics alongside neon to extend the color gamut by as much as 30 percent. Kornit’s new Vivido inks now additionally offers the industry’s richest, dark black pigments.

Kornit Digital will feature a view into the end-to-end, fabric manufacturing ecosystem – allowing for production of any fabric and any design for any purpose. The centerpiece is Kornit Presto MAX, rapidly transforming the digital world of fabric printing with an ability to print on any fabric type – from cotton and polyester to denim and leather. This single-step solution sets new benchmarks in both textile design and manufacturing across fabrics, home décor, and more. Built on the promise of sustainability, Presto MAX is proven to dramatically reduce both water usage and waste – ensuring businesses can thrive in an eco-conscious marketplace. The system is the world’s first offering to print white ink on colored fabrics alongside neon to extend the color gamut by as much as 30 percent. Kornit’s new Vivido inks now additionally offers the industry’s richest, dark black pigments.

Additionally featured is the KornitX Global Fulfillment Network, a game-changing solution designed to optimize operational efficiency, eliminate supply chain bottlenecks, and ensure products are readily available to meet customer demands. The solution connects brands, retailers, and digital platforms to a high-quality production network – providing rapid replenishment and trend adaptability for direct-to-fabric production. Revolutionary pixel-to-parcel monitoring and control fully integrates the end-to-end production workflow for a seamless experience. The solution based on Kornit’s game-changing MAX technology empowers brands to break free from traditional constraints and unlock their true potential. It enables them to maximize margins, boost profitability, and pave the way for a sustainable future in the digital on-demand fashion and textile industry.

Additionally featured is the KornitX Global Fulfillment Network, a game-changing solution designed to optimize operational efficiency, eliminate supply chain bottlenecks, and ensure products are readily available to meet customer demands. The solution connects brands, retailers, and digital platforms to a high-quality production network – providing rapid replenishment and trend adaptability for direct-to-fabric production. Revolutionary pixel-to-parcel monitoring and control fully integrates the end-to-end production workflow for a seamless experience. The solution based on Kornit’s game-changing MAX technology empowers brands to break free from traditional constraints and unlock their true potential. It enables them to maximize margins, boost profitability, and pave the way for a sustainable future in the digital on-demand fashion and textile industry.

Beyond technology demonstrations, Kornit will additionally highlight how MAX technology serves as a vibrant partner platform to drive possibilities across the entire fabric printing and processing chain. Key partners highlighted include:

• Colortex: Providing fashionable, custom textiles for the footwear industry.

• ZwissTex: Offering quality, sustainable textile solutions for the automotive and clothing sectors.

• Print Logistic: Delivering a full range of services – from printing to worldwide drop-shipping for smooth e-commerce integration.

• CGS: Driving global performance through business applications, enterprise learning and outsourcing services.

• FastSwen: Leveraging Moving Cavity Technology (MCT) to transform textile handling and production efficiency.

• Premier Digital Textiles: Serving as the prime supplier of textiles with extensive warehousing across the US and UK.

• Greentex: Providing highly sustainable, innovative, and customizable fabrics for advanced textile printing.

To experience the unmatched power of on-demand, sustainable textile production, don’t miss the opportunity to visit Kornit Digital at Texprocess 2024. Witness the future of digital production at Hall 8, Stand A32.

Lectra unveils the new version of its collection management software, Kubix Link PLM, to the fashion industry

Lectra, a major Industry 4.0 player in the fashion, automotive and furniture markets, announces a major development of its SaaS platform dedicated to collection management for the fashion sector: Kubix Link 3.4 This new version improves optimization at each phase of bringing a product to market, from design to marketing. Its launch goes hand in hand with that of Kubix Forms, a solution that simplifies the collection and integration of data from third-party users on the Kubix Link platform.

Lectra, a major Industry 4.0 player in the fashion, automotive and furniture markets, announces a major development of its SaaS platform dedicated to collection management for the fashion sector: Kubix Link 3.4 This new version improves optimization at each phase of bringing a product to market, from design to marketing. Its launch goes hand in hand with that of Kubix Forms, a solution that simplifies the collection and integration of data from third-party users on the Kubix Link platform.

To maintain their profitability in the face of current economic instability and intense competition, fashion brands must reduce their costs. While collection renewals are accelerating, brands must also optimize their production operations. Finally, they must respond to increasing requirements in terms of sustainability, compliance and traceability.

In this context, it has become absolutely essential to have information that is as accurate and up-to-date as possible at each stage of the product lifecycle. Fashion brands also need to be able to very simply and easily share this product information with all those involved in the design, manufacture, distribution and marketing of their collections.

A better user experience with Kubix Link 3.4

With Kubix Link PLM, Lectra already had a cloud-hosted SaaS platform offer that included functions for product lifecycle management (PLM), product information management (PIM) and data asset management (DAM). Kubix Link 3.4 enhances the user’s experience through new media organization (photos, videos), greater data storage capacity, increased flexibility in using the tools offered, as well as improved translation to facilitate cooperation between multilingual teams.

This new version also provides transparent integration of third-party solutions, similar to AccuMark, Lectra’s patternmaking software, or the brand new offer, Kubix Forms. This is being launched in parallel with Kubix Link 3.4 to make it easier for fashion brands to collaborate with their external partners.

“Kubix Link is already used by 300 customer brands and we are the European leader in product data management and collaboration. We want to go further by continuing to develop innovative solutions to respond to the new needs of our customers. The fashion industry evolves very quickly. We are happy to be able to participate in this transformation by providing responses based on our mastery of new technologies and our expertise in each sector, gained from Lectra’s experience working hand in hand with the most renowned fashion brands for over 50 years,” explains François Gonnot, Product Marketing Director at Lectra.

Broader collaboration made simpler with Kubix Forms

Launched at the same time as Kubix Link 3.4, Kubix Forms revolutionizes the collaboration between fashion brands and their partners. Third-party users can fill out and expand the information available on Kubix Link. It is now possible to overcome traceability challenges by retracing the origin of textiles and calculating their carbon footprint, to check production quality and interact transparently with suppliers and brands to obtain product information more easily. Automatic response integration in Kubix Link ensures that work flows smoothly, reducing time spent on manual data entry, and promotes data enrichment in a secure manner for brands.

François Gonnot concludes, “Fashion brands need more transparency, traceability, compliance and collaboration. The Kubix Forms offer gives them the opportunity to make significant advances in optimizing their business processes and maximizing their operational efficiency, regardless of their size. With the integration of Kubix Forms, Lectra is providing a proactive response to the growing demand for smooth collaboration with third-party users. We therefore offer a significant competitive advantage to customers who trust us to actively contribute to their growth and success.”

Step up to assured fabric quality for technical and sensitive applications with Uster Technologies

Uster Technologies offers a flexible solution to upgrade fabric inspection from manual to automated. Integration in existing production lines is quick and easy, and the data flow also brings extra benefits. It means fabric producers can significantly improve their yield with fast, accurate quality monitoring.

Uster Technologies offers a flexible solution to upgrade fabric inspection from manual to automated. Integration in existing production lines is quick and easy, and the data flow also brings extra benefits. It means fabric producers can significantly improve their yield with fast, accurate quality monitoring.

Any change starts with a new thought and a clear intention – but sometimes it takes time to make it happen. That’s because issues might be expected during implementation. But that’s not the case when switching from manual to automated fabric inspection with Uster. This article presents the key points, and offers further options for total understanding: discussing the benefits with an Uster expert at the upcoming Techtextil or on another occasion; or taking part in a special webinar on April 11.

The path to automation

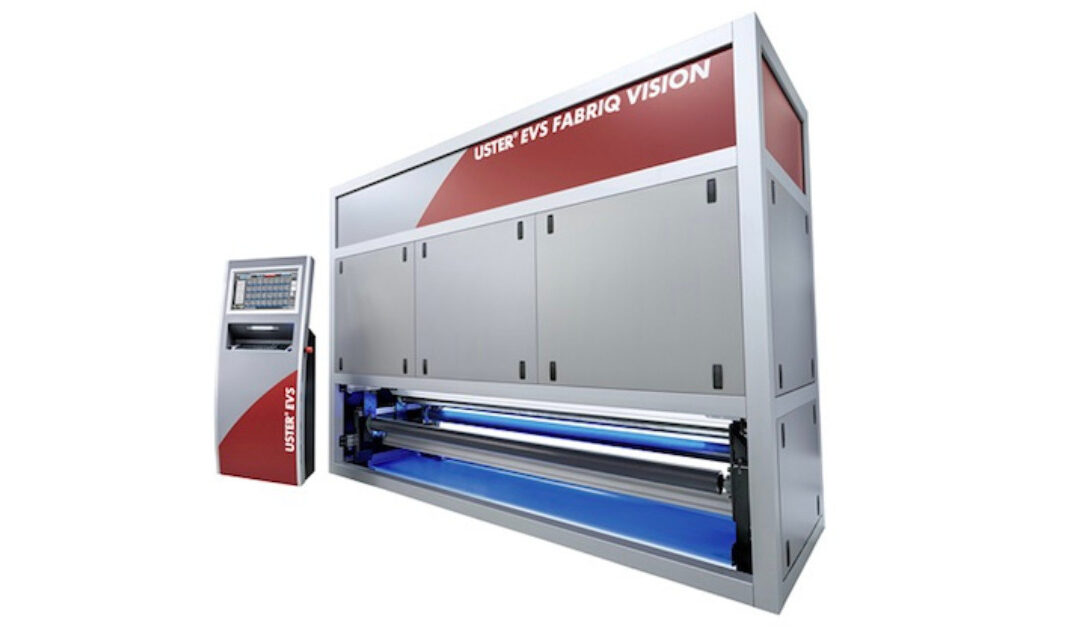

For maximum benefits – up to 50% lead time savings and 80% less waste – automated fabric inspection combines Uster EVS Fabriq Vision with Uster Fabriq Assistant. This integrates a reliable and sophisticated inspection system, delivering vital data, with practical analysis of that data to deliver the best results for users.

Prerequisites for automatic fabric inspection begin with a detailed evaluation of the current process, to identify the critical steps. Typical questions users will be asked include “what kind of optimization do you expect and what changes would you like to make to the production process?” Or “how does your final process step look before you ship the fabric to your customer?”

At the end of this analysis, the steps towards integration are planned, including the choice of the right hardware and software needed to achieve automation in the fabric inspection process.

The Uster Fabriq Vision inspection solution can be integrated into existing production lines – or used as an off-line inspection system. In both cases, the preconditions for optimal results from the optical system are the same: smooth and tension-controlled fabric flow, no creases in the fabric, stable light conditions in the inspection area and no dust or lint on the fabric.

The inspection cameras feature state-of-the-art technology, positioned at various detection angles. Sophisticated illumination makes defects visible and raises detection performance to the maximum. Uster EVS Fabriq Vision provides real-time alerts for operatives, showing all defects and automatically creating roll inspection charts. All detected faults are collected in a dataset and transferred to Uster Fabriq Assistant.

Data flow

Data generated by Uster fabric inspection systems feeds to Uster Fabriq Assistant, which creates statistics for quality and process improvement. Its automated features make Uster Fabriq Assistant more efficient and productive, as a reliable and tailored solution for processing, analyzing, and visualizing quality data.

Connecting data is no longer a big deal. The Uster solution offers an open interface to transfer data to the ERP system and to the Optimized Cut Control (OCC), allowing maximized yield. Uster recommends a customer workshop to discuss data requirements, key parameters, data flow in production and how to create a powerful infrastructure.

Additional benefits

OCC allows an increased fabric yield after inspection. It is a software tool using the defect map from inspection, enabling automated cut optimization to be installed on any existing debatching or cutting line. It automatically identifies the correct cutting position for maximum fabric yield according to the customer’s quality requirements, and makes the cutting process highly efficient.

Invisible synchronization marks (applied during inspection) indicate the position of defects and cut positions in a roll, so these are always under control, allowing the cutting table to run at maximum possible speed.

When color consistency is critical, Uster EVS Fabriq Shade supports fabric producers to deliver a constant shade in end-products. The system provides standard shade measurements with high accuracy and continuously qualifies shade variation, based on a set reference point. To ensure lots have optimal color uniformity, the system offers grouping according to shade, for best fabric yield. Combining Uster EVS Fabriq Shade and Uster EVS Fabriq Vision in one process provides all relevant quality data in a single operation and increases the efficiency of fabric inspection.

The change explained

Automated fabric inspection requires newly-configured logistics as part of the detailed set-up plan – including a clear and traceable data flow for a paperless production. Finally, the calculation of the ROI will assure customers that profitability – as well as efficiency and quality – will also increase.

Ingo Kiefer, Senior Textile Technologist for fabric inspection at Uster Technologies, takes participants through the transition from manual to automated fabric inspection at the upcoming webinar. Uster Technologies also invite interested parties to face-to-face discussions at Techtextil Frankfurt, from April 23 to 26, 2024. Meet their fabric inspection experts at the Elmatex booth D63 (Uster agent for Germany) in hall 12.