Orange O Tec Prepares for Takeoff with ‘Rocket’

India Awaits the Arrival of Homer’s Hybrid Digital Textile Printing Marvel with Up to 60,000 LM/Day Capacity

Orange O Tec has introduced ‘Rocket’, the hybrid single-pass digital textile printing machine to the Indian market. Engineered for unmatched speed, precision and environmental performance, Rocket is redefining the standards of digital textile printing capable of delivering speeds of up to 60,000 LM/day.

With support for pigment, reactive and disperse inks, Rocket is designed to serve the evolving needs of India, Bangladesh, and China’s dynamic textile industries. Its flexibility makes it the ideal solution for both bulk production and bespoke design driven applications.

Advanced Innovation: Hybrid Workflow Meets High Speed Output

The Rocket system is a fully integrated single-pass digital textile printer that automates the entire production flow from fabric feeding to final drying and collection-delivering high efficiency and minimal manual intervention.

Core Components Include:

• Fabric Feeding Unit

• Inline Coating

• Belt Guiding System

• Patented Online Fabric Sizing Station

• High-Speed Inkjet Printing Module

• Controlled Drying Chamber

• Smart Fabric Collection Unit

Versatile Fabric Applications & Ink Compatibility

Rocket provides exceptional print quality across a wide variety of textile substrates, thanks to its compatibility with multiple ink types. Its pigment ink capabilities, in particular, enable sustainable, water-free printing across:

• Natural fibres: Cotton, Viscose, Linen, Hemp

• Blended woven fabrics: Cotton-polyester, Viscose blends

• Synthetic textiles: Polyester-rich fabrics (with disperse ink)

Pigment Ink Advantage

As the textile industry moves toward greener practices, pigment ink stands out for its elimination of post-processing like steaming or washing. Rocket leverages this to significantly reduce water and energy consumption, while maintaining excellent durability, colour brilliance and light fastness-especially on natural fabrics.

Key Benefits of the Rocket System

No Plates, No Delays

Digital on-demand printing allows for instant setup, with no plate-making, unlimited repeat sizes, and intricate multi-colour designs.

True Hybrid Power

Rocket uniquely combines digital inkjet precision with rotary screen versatility and in line coating enabling a wide range of value-added effects, including:

• Metallic foils (gold/silver)

• Pearl and glue paste applications

• Colour-shifting inks

• Embossed and textured finishes

Patented Online Sizing Technology

Rocket’s integrated sizing station enhances efficiency by:

• Delivering up to 5000 metres per paste barrel

• Reducing paste consumption by up to 50%

• Cutting nitrogen emissions by nearly half

Ink Efficiency & Colour Brilliance

A wet-in-wet printing process allows for superior ink penetration and enhanced vibrancy:

• Up to 15% brighter colours

• 10–15% reduction in ink usage, lowering both costs and environmental impact

Market Impact Across Asia

China: Leading the Smart Factory Transformation

Rocket has already reshaped the production capabilities of Chinese textile giants. Shaoxing Shengxin Printing and Dyeing Co., Ltd. operates 6 Rocket units, printing over 3,00,000 square metres daily, enhancing product quality, reducing waste, and lowering labour dependency. To date, 25 Rocket machines have been installed in China, signalling strong market demand and alignment with the nation’s smart manufacturing initiatives.

Bangladesh: Driving Value-Added Export Growth

Rocket debuted in Bangladesh at the Dhaka International Textile & Garment Machinery Exhibition (DTG), catalyzing the country’s shift from bulk exports to customized, high-value manufacturing. With 9 machines already in pipeline, Rocket is helping Bangladeshi manufacturers elevate design capabilities, flexibility and export value.

India: Powering Surat, Tirupur & Emerging Textile Hubs

In India, Rocket is expected to arrive soon, and anticipation is already high in major textile hubs like Surat and Tirupur. The machine will support:

• Compliance with India’s ESG goals

• Rapid turnaround for short-run and customized orders

• Entry into premium global markets via high-end, sustainable printing

Rocket’s pigment ink support also positions it as a top choice for eco-conscious manufacturers aiming to reduce water use and eliminate post-processing.

Sustainable Engineering at Its Core

Sustainability is integral to Rocket’s design and engineering. Key features include:

• Low-temperature drying oven for reduced energy consumption

• Odour control and disinfection system for hygienic fabric output

• Streamlined system architecture to eliminate redundant machinery, saving space and operational costs

By minimizing post-processing and optimizing every stage of the workflow, Rocket drastically lowers both environmental impact and production overheads.

Final Word: A Platform for Future-Ready Printing

The Rocket hybrid single-pass digital textile printer is not just a machine – it’s a transformative solution for forward-thinking textile manufacturers. Whether you are printing natural fibres with pigment, blends with reactive, or synthetics with disperse, Rocket empowers your business with speed, flexibility and sustainability.

Introducing the Monna Lisa ML-18000, the latest innovation in Epson’s Monna Lisa digital textile printer lineup

Epson, a global leader in digital imaging and printing technologies, today announced the launch of the latest addition to its flagship Monna Lisa series of digital textile printers. As the global textile industry embraces a digital transformation, there is a growing need for technologies that offer speed, flexibility, and environmental responsibility without compromising on quality. Digital textile printing has emerged as a vital enabler of this shift — allowing for agile production, reduced resource consumption, and stunning visual expression across a range of fabrics and applications.

Epson, a global leader in digital imaging and printing technologies, today announced the launch of the latest addition to its flagship Monna Lisa series of digital textile printers. As the global textile industry embraces a digital transformation, there is a growing need for technologies that offer speed, flexibility, and environmental responsibility without compromising on quality. Digital textile printing has emerged as a vital enabler of this shift — allowing for agile production, reduced resource consumption, and stunning visual expression across a range of fabrics and applications.

In response to these evolving demands, Epson is now launching the Monna Lisa ML-18000 — the latest innovation in its flagship series of high-performance digital textile printers. Designed to deliver unparalleled performance for high-volume production, the ML-18000 offers exceptional print speed, enhanced color depth, and sustainable performance making it a powerful solution for the evolving needs of the textile and fashion printing industries.

Unmatched Productivity with Double Black Ink and PrecisionCore Technology

At the heart of the ML-18000 are 18 Epson PrecisionCore® Micro TFP printheads, enabling production speeds of up to 252 sqm/h in 2-pass mode (600 x 600 dpi), while maintaining outstanding print quality. Its double black ink configuration delivers significantly improved black density, enabling deep, rich tones at high speeds—ideal for applications across fashion, home décor, and soft signage. Compared to its predecessor, the Monna Lisa ML-16000, the ML-18000 utilises a higher proportion of black ink, achieving improved optical density with greater cost-efficiency, especially for dark and monochromatic designs.

Sustainable Performance with Reduced water usage

In line with Epson’s commitment to sustainability, the ML-18000 features an Integrated Water Recycling Unit which conserves valuable water resources by filtering and recycling water used in belt cleaning processes. A built-in sensor continuously monitors the level of water contamination, ensuring maximum recycling efficiency in compliance with local wastewater drainage regulations˟¹. This compact, efficient system reduces water consumption, helps meet local wastewater regulations, and minimizes environmental impact- making it an ideal solution for eco-conscious production environments.

Monna Lisa Quality: Powered by Epson Precision Technologies

The ML-18000 integrates Epson’s advanced Precision Dot Technologies, including microweave and lookup table technologies that reduce banding and graininess. Its multi-layer halftone technology that randomizes halftone dot patterns to reduce visual artifacts and ensure smoother gradations. Additional features like symmetrical color alignment, accurate belt position control, and Epson Edge Print PRO X is genuine Epson RIP software which supports Adobe PDF Print Engine (APPE) – the industry’s leading technology with 16-bit rendering guarantee high-speed and high quality outputs with exceptional detail, clarity, and accuracy—crucial for complex designs and fine patterns.

Engineered for Ease and Efficiency

The ML-18000 is built for non-stop operation. It features a dual 10-liter ink system, high-efficiency cleaning mechanisms, and automated maintenance tools, including auto nozzle verification technology, fabric wiper cleaning, a fluff blower system, ink mist extraction system, and auto calibration powered by an integrated RGB camera. These ensure consistent print quality while minimizing downtime.

Environmentally friendly inks

The ML-18000 uses Epson GENESTA Reactive Inks, which are ECO PASSPORT certified to meet globally recognized standards for environmentally friendly textile printing, and GOTS-approved by ECOCERT˟². These inks deliver brilliant color reproduction while minimizing environmental impact.

Connected for Smart Management

The printer is supported by Epson Cloud Solution PORT, which allows users to monitor printer performance remotely from a PC or mobile device helping to maximize productivity˟³. This real-time visibility enhances workflow productivity and enables Epson’s service teams to diagnose issues remotely, ensuring faster resolution and minimal disruption.

Applications

The ML-18000 is ideal for producing high-quality prints on various fabrics, including silk, cotton, polyester, and blends. Its versatility makes it suitable for diverse markets such as haute couture, fast fashion, home textiles, and sportswear

Key Specifications at a Glance:

• Printheads: 18 Epson PrecisionCore MicroTFP printheads

• Print Speed: Up to 450 sqm/h (300 x 600 dpi, 1 pass˟⁴), 252 sqm/h (600×600 dpi – 2 pass˟⁵), 162 sqm/h (900×600 dpi – 3 pass˟⁶)

• Resolution: Up to 1200 dpi

• Print Width: 185 cm

• Ink Colors: 8 (Black, Cyan, Magenta, Yellow, Grey, Red, Blue, Orange, Crimson)

Satyajeet Satpathy, Director – Sales & Marketing, Epson India, says, “The Monna Lisa ML-18000 is a next-generation digital textile printing solution designed to meet the growing demand for high-speed, high-quality, and sustainable printing. With double black ink technology, an integrated water recycling system, and a robust Epson ecosystem, it empowers textile printing businesses to stay competitive while advancing responsible production practices.”

˟¹ Costs and compliance with local wastewater drainage regulations will vary according to print volume and the locale in which the printer and water recycling unit are used

˟² Genesta RE-N Reactive inks: except one of Grey (Grey RE-N)

˟³ All features of this system require an active internet connection and use of a supported browser

˟⁴ With 300x300dpi 2 Half Tone layers

˟⁵ With 300x300dpi 4 Half Tone layers

˟⁶ With 300x300dpi 6 Half Tone layers

DyeMate: three steps to revolutionize indigo garment dyeing

At Tonello, we decided to rewrite the rules of indigo dyeing with DyeMate—the technology that has taken the market by surprise and revolutionized the way garments are dyed. In just two years, DyeMate has made huge strides, transforming not only the dyeing process itself but also the entire creative vision surrounding indigo.If you’ve never heard of DyeMate, now is the perfect time to discover why it’s changing everything.

The evolutionary stages of DyeMate

1. Indigo as you’ve never seen it before

1. Indigo as you’ve never seen it before

It all began in 2023 with the debut of DyeMate, which introduced a new perspective on indigo garment dyeing. Starting from a traditional process, we made it modern, efficient, and most importantly, reproducible.

DyeMate marked a major turning point in indigo garment dyeing, thanks to several standout features that make this technology a true must-have:

• Fully automated process, ensuring higher efficiency and control

• Maximum reproducibility of effects, guaranteeing consistent, high-quality, and perfectly repeatable results

• Authentic, brilliant indigo, preserving the charm of tradition while maintaining the most genuine, lived in denim aesthetic

This first step brought indigo dyeing into the innovation era, inspiring designers and brands with creative possibilities that once seemed impossible.

2. New hues, new possibilities

In the first half of 2024, we took the next step introducing a special ingredient: sulfur. DyeMate is now capable of dyeing garments not only with VAT dyes but also with sulfur dyes. This development changed everything, allowing for the creation of incredible hues and chromatic tones -like red, black, and green- that are inspired by the denim world but also suitable for garments ready for dyeing.

This evolutionary phase led to:

• New color shades, reinterpreting classic indigo with original highlights

• A new aesthetic language, inspired by denim yet adaptable to different styles and materials

3. Sulfur Essence: the revolution within the revolution

And now, the latest and most incredible step: Sulfur Essence. In this innovation, indigo and sulfur come together in a single dyeing bath, with sulfur playing the leading role. The result? Discharged and overdyed denim effects with authentic contrasts-applied to garments ready for dyeing.

But it’s not just about aesthetics:

• The process runs at room temperature, reducing energy consumption and preserving the original characteristics of the fabric

• A single dye bath optimizes time and resources, reducing waste

• Garments ready for dyeing can be transformed with stunning effects, opening up new personalization possibilities

Why is DyeMate so special?

If you’ve never worked with indigo, you might think garment dyeing is simple. But in reality, every shade and every detail requires precision and technique. DyeMate not only simplifies the process, making it more manageable, but also delivers results that once seemed unimaginable.

If you’ve never worked with indigo, you might think garment dyeing is simple. But in reality, every shade and every detail requires precision and technique. DyeMate not only simplifies the process, making it more manageable, but also delivers results that once seemed unimaginable.

• Laser-friendly compatibility: high-contrast, sharply defined markings ideal for detailed personalization

•Washing effects: DyeMate dyes are perfect for subsequent treatments with Core 2.0, EGO, and NoStone®, allowing for unique finishes in a single cycle

• Denim look: replicating overdyed denim effects on garments ready for dyeing expands the boundaries of creativity

In just three steps, DyeMate has transformed the landscape of indigo garment dyeing… giving designers and brands the tools to create extraordinary pieces in a responsible and automated way.

And this is just the beginning. Who knows where the next chapter will take us? We’re ready to find out. Are you?

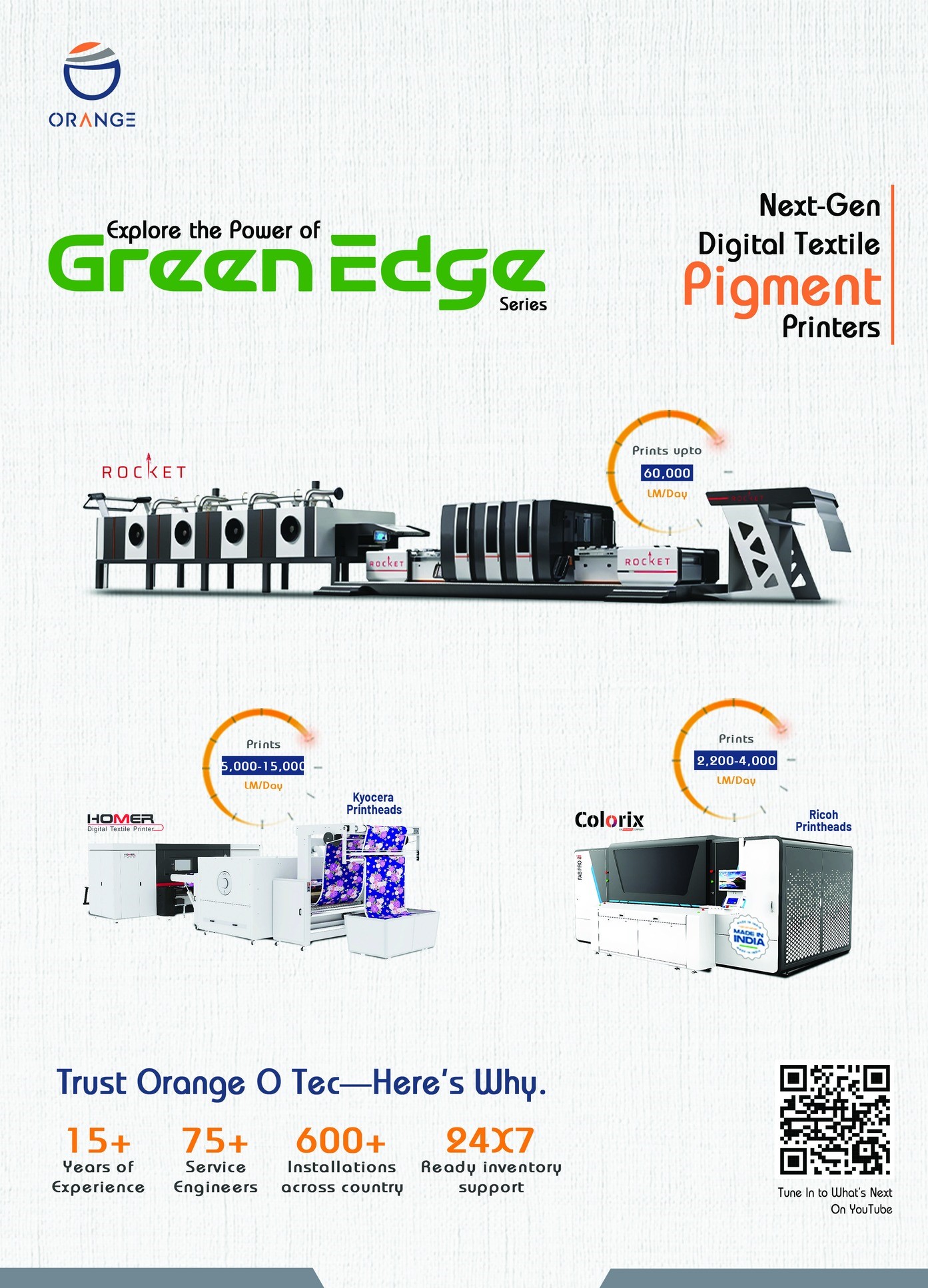

Orange O Tec Sparks South India’s Pigment Printing Surge with Homer K24 Green Edge Series at Macrofast

Tirupur, Tamil Nadu — In a landmark move for South India’s textile sector, Orange O Tec has successfully installed its first-ever Homer K24 digital textile printing machine at Macrofast, a pioneer in organic fabric and apparel manufacturing since 1984. This strategic collaboration not only enhances Macrofast’s production capabilities but also establishes Orange O Tec’s strong presence in South India’s growing digital textile market.

Tirupur, Tamil Nadu — In a landmark move for South India’s textile sector, Orange O Tec has successfully installed its first-ever Homer K24 digital textile printing machine at Macrofast, a pioneer in organic fabric and apparel manufacturing since 1984. This strategic collaboration not only enhances Macrofast’s production capabilities but also establishes Orange O Tec’s strong presence in South India’s growing digital textile market.

About the Homer K24 Digital Textile Printing Machine

The Homer K24 represents the latest generation in industrial digital textile printing technology. Renowned for its high-definition output and operational efficiency, it is built to meet the rigorous demands of large-scale fabric production while maintaining exceptional print quality.

Key Specifications:

• Maximum Printing Speed: Up to 5,000 linear meters/day

• Production Efficiency: 50% higher output than 16-head models at just 20% additional cost

• Maximum print width is 72 inches, enabling wide-format textile printing with exceptional precision

• Compatible Media: Cotton, Linen, Silk, Nylon, Polyester, and Blended Fabrics

• Printhead: Equipped with advanced Kyocera Katana printheads for superior sharpness and durability

The K24 offers seamless integration with a wide range of ink types, particularly pigment inks, making it an excellent choice for sustainable textile production.

Why Macrofast Chose the Homer K24 from Orange O Tec

Macrofast have a state-of-the-art 70,000 sq. ft. facility in Tiruppur, housing modern organic fabric storage systems, advanced garment sewing lines, and cutting-edge digital print zones including pigment, reactive, and hybrid DTG printing.

To align with its vision of eco-conscious, high-quality production, Macrofast sought a digital solution that could deliver:

• Consistently sharp, vibrant prints

• High-speed output to meet growing demand

• Compatibility with a broad range of fabrics

• Proven performance with Kyocera Katana printheads

The Homer K24 emerged as the ideal fit, offering both reliability and the ability to scale up sustainably.

Major USPs of the Homer K24

• Advanced Kyocera Katana Technology: Ensures high-resolution, reliable, and consistent printing

• Hybrid Ink Compatibility: Supports pigment, reactive, and disperse inks

• Built for Industrial Use: Engineered for 24/7 operations with minimal maintenance

• User-Centric Design: Intuitive interface for easy operation and control

• Energy-Efficient Drying & Finishing: Seamlessly integrates with modern finishing systems

The Future of Digital Textile Printing in South India

Tirupur—long recognized as a global hub for knitwear and apparel—now stands at the forefront of digital textile transformation. The successful deployment of the Homer K24 at Macrofast paves the way for more manufacturers in South India to embrace digital printing technologies that:

• Increase productivity

• Promote environmental sustainability

• Enable faster delivery cycles

• Offer flexibility for customization and shorter runs

Orange O Tec is poised to lead this digital revolution, empowering textile businesses to compete on a global scale through innovation and sustainable practices.

Conclusion

Macrofast’s investment in the Homer K24 is more than a technological upgrade—it’s a bold step toward the future of textile manufacturing. With this move, Macrofast reinforces its legacy of quality, innovation, and environmental responsibility.

As the demand for high-speed, eco-friendly printing continues to grow, Orange O Tec’s Homer K24 stands out as a powerful solution driving progress in South India’s textile industry.

Key Highlights: Homer K24’s Pigment Ink Compatibility

• Specifically optimized for high-performance pigment printing

• Requires minimal pre and post-treatment, reducing water and energy usage

• Delivers bright, long-lasting colors with excellent wash and rub fastness

• Perfectly aligned with the needs of organic and sustainable fabric production

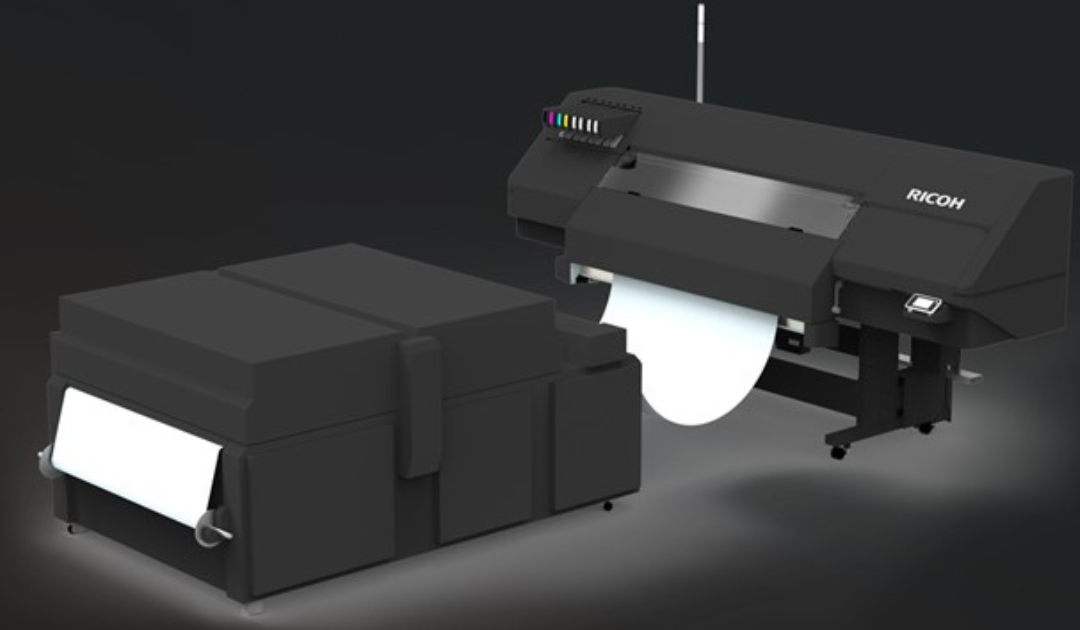

Ricoh to showcase textile production at FESPA

Ricoh will be demonstrating next generation textile on demand production versatility at FESPA Global Print Expo 2025, Europe’s premier exhibition for screen, digital, wide format, and textile printing, Messe Berlin, from May 6 to 9.

Ricoh will be demonstrating next generation textile on demand production versatility at FESPA Global Print Expo 2025, Europe’s premier exhibition for screen, digital, wide format, and textile printing, Messe Berlin, from May 6 to 9.

Meeting the high volume digital production demands of industrial markets will be the RICOH Pro™ D1600 DTF system. Ricoh’s industrial printheads help it achieve speeds in excess of 20 sqm per hour for media widths of up to 1300mm film.

Presenting opportunities in production on polyester fabrics for apparel decorators and designers alike is Ricoh’s Ri 4000 DTG printer. The system’s inbuilt pre-treatment process facilitates consistent, vibrant, and efficient industrial garment printing at an affordable price.

These systems incorporate Ricoh inkjet technology designed to deliver speed, versatility, durability, and accurate fluid deposition, with minimal maintenance. While ensuring the effective management of consistent and reliable colour accuracy is ColorGATE (a Ricoh company) Productionserver Version 24 which will be driving all textile devices on show.

Furthermore, the textile systems support just in time, on demand, local production capabilities that reduce waste, maximise resources, and eliminate unnecessary transportation.

Ricoh will also expand on how its Valvejet technology aligns with the industrial painting and coating market’s need for higher viscosity fluids and throw distances along with larger drop sizes. Demonstrating the possibilities will be Ricoh’s industrial tyre printing solution developed for the high end customisation market.

Focus will also be on the R & D developer community where collaboration between suppliers can facilitate fast time to market. Printheads, drive electronics, drop watching, and curing are key elements in a fragmented supply chain and Ricoh will advise visitors on navigating this complex process.

Graham Kennedy, General Manager, Industrial Solutions, Ricoh Printing Solutions Europe, says: “Ricoh technology powers a wide range of industrial solutions and we are looking forward to demonstrating real life applications at FESPA. The potential for innovative development with partners and clients is limitless.”

Unleash Infinite Possibilities with Zimmer’s MAGNOROLL: The Ultimate Multi-Purpose Coating Solution

Zimmer Austria, based in Klagenfurt is a leading manufacturer of superior machines tailored for the textile printing and coating sector. With a legacy spanning more than 150 years, Zimmer has established itself as a benchmark for dependable, high-class machineries in textile.

Zimmer Austria offers a comprehensive range of high-quality machines for textile printing and coating. Its main products include:

• Screen printing: Ideal for high-quality mass production with vibrant and bold colours

• Coating systems: Multipurpose solutions for applying liquid, paste, and foam coatings on various materials

• Drying systems: Efficient drying solutions integrated into coating and printing lines

• Steaming systems: Essential for fixing dyes and finishes in textile production

Introducing the Zimmer MAGNOROLL

The Zimmer MAGNOROLL is a state-of-the-art multipurpose coating machine designed to meet the diverse needs of various manufacturers. Known for its versatility and precision, the MAGNOROLL offers a range of advanced features that makes it a standout choice for coating applications.

The MAGNOROLL can be installed into an existing stenter coating line or as a special designed coating plant with web infeed, dryer and exit. The modular system allows a combination with:

• Working widths spanning from 500 mm (20 in.) to 4800 mm (189 in.)

• 1 or 2 rotary screen-printing aggregates, repeat 640–914 mm, for designed and full surface application with Zimmer roll rod and magnet blade squeegee technology

• Magnet roll direct coating and low-add-on application

• Knife coating with knife-on-air and knife-over-roll application technology

• Slot nozzle device MAGNOJET and/or VARIOPRESS for full surface foam coating

• Contact or contactless single or double-sided application in horizontal and/or vertical installation can be realised

Zimmer has mastered various application methods to suit different needs. Here are some of the key methods:

• Magnet roller technology

• Rotary screen with/without magnet system

• Screen to screen

• Knife on air

• Knife over roll (with high precision counter roller for paste application)

• Different foam application devices

The MAGNOROLL is designed for a wide range of applications, including:

• Textiles and technical textiles: Suitable for coating liquid, paste, and foam on various textile materials.

• Innovative materials: Effective for substrates such as glass fibre, paper, film, plastics, nonwovens, carpets, and other innovative materials.

• Specialised coatings: Ideal for applications requiring infrared reflective camouflage, flame retardant, water repellent, silicone coating, dirt repellent, and thermal insulation.

Benefits:

• The only true multi-purpose coating machine in the market, capable of handling a wide range of materials and coating methods

• Tailored to meet specific customer needs, ensuring optimal performance and results

• Designed to minimise energy consumption while delivering outstanding results

• Ensures consistent and high-quality coating applications, enhancing the final product quality

• Substrates can be sent with different chemistries for product development

• Tests conducted independently or collaboratively

• Chemistry suppliers are invited on-site modifications and adjustments to recipes

Development centre capabilities

· Realistic testing conditions:

– Machine mimics the design of original production machines

– Ensures accurate and realistic testing environments

· Trial process:

– Trials typically commence on the smaller coating line

– Maximum working width of 620 mm for initial trials

– Option to replicate trials on the second coating line upon request

– Second coating line has a maximum working width of 2,200 mm

– Designed to bolster your confidence in the results.

· Customisation:

– In-house mechanical engineering and electrical assembly capabilities

– Tools tailored to precisely match your specific requirements

This setup ensures that you can test and refine your coating processes under conditions that closely resemble actual production, providing you with reliable and actionable insights.

A.T.E. Enterprises Private Limited, with over 85 years of expertise, proudly serves as the exclusive agent for Zimmer machinery in India. Our commitment to excellence has earned the trust of leading textile manufacturers, including Welspun Living, D’Decor, Candor Textiles, Kusumgar, and Vista. These industry leaders have chosen Zimmer MAGNOROLL for their production needs, reinforcing A.T.E.’s reputation for delivering top-tier solutions. By integrating Zimmer MAGNOROLL into their processes, these industry leaders not only enhance their product quality but also ensure greater customer satisfaction through reliable and superior performance and consistent finishing that meets international standards.

The Zimmer MAGNOROLL is a testament to their commitment to innovation and excellence in the textile coating industry. Whether you’re looking to enhance your existing production line or explore new coating possibilities, the MAGNOROLL offers the flexibility and precision you need to achieve exceptional outcomes.