Automation for apparel manufacturing by Ample Garment Machinery

Mohammad Bilal, Senior Brand Executive & Country Manager, Ashima Machinery (Ample Garment Machinery)

When you think of starting a business in garment manufacturing, the first thing you should do gather is knowledge on machinery and basic equipment you need for making the garments manufacturing. There is a wide range of machineryfor different processesin apparel manufacturing from design development to fabric checking to garment packing. What types of machines and technology one need to install for the manufacturing business, depend on the product variety and investment capability?

Starting a business in the garment industry can be considered as one such good option. You can startyour businessin the garment manufacturing sector or start your own clothing label (brands) and open a retail store. Anyone can enter into the garment manufacturing business. I have seen many newcomers are from different fields like IT professionals, bankers, and HR professionals who have started their businessin thisindustry

In this article, Ample GarmentMachinerywill provide you information for alltypes of machinery and equipment required for setting up a garment manufacturing business. Ifyou look at garmentmanufacturing processes,theyinvolves processes like – sample development, pattern making, fabric inspection, fabric spreading, fabric cutting, garment stitching, garment checking, garment pressing, repair work, garment folding, and packing. In all these processes, a different set of machinesis used. The majority of machines are stitching machines.

Fabric Testing and Fabric Inspection

In garment manufacturing, fabric plays an important role in garment quality and product valuation as well as customer demand. Secondly, 60-70 percent of the cost is incurred in fabrics in total garment costing. That is why purchasing the right quality fabric for your products is necessary. For verifying the fabric quality parameter, garment manufacturers prefer to set-up in house fabric testing.

Fabric Spreading Machines

For small-scale garment manufacturing, manual spreading is viable. But if you want to scale up your business, improve cutting room productivity and reduce cutting room manpower, automatic spreading machines must be considered

Product Designing and Pattern Making

For the pattern making of the sample products, you may be interested in software. For this, you can purchase CAD (computer-aided design). There are other components of the CAD systems – pattern grading, marker planning, nesting and pattern digitization. For printing the marker paper, you need a plotter machine. With the help of CAD software, you can estimate fabric requirements accurately and improve the garment fit.

Cutting Room Machines and Equipment

With the technology advancement, cutting automation is preferred by medium and large-scale garment manufacturers. Cutting room efficiency is improved by many folds after using an automatic textile fabric cutting machine.

Sewing Machines

Sewing machines are the heart of the garment manufacturing factories. Different types of sewing machines are available for making the garment products. You need to select the right mix of sewing machines for your products or product groups. For the selection of sewing machines and the number of sewing machines needed to be purchased for setting up your factory, you can take advice from an expert in industrial engineering in Ample Garment Machinery.

Finishing Machines and Equipment

Various types of finishing equipment are required. Like, garment pressing equipment – vacuum table and steam iron for pressing garments.

Garment Packing

Garment folding is normally done manually. But a garment folding template is available in the market. In the garment packing stage, hangtags must be attached to the garment. For tagging, you need a tag gun machine.

If you are making garments, one of the compliance parameter is that all garments must be passed under needle detector machines. You may need to buy a needle detector machine

Revolutionizing Textile Printing in India – NKT F Series Pigment Printing Machine from Apsom Technologies

Apsom Technologies, a leader in digital textile printing solutions, has partnered with NKT (New King Time) to introduce the NKT F Series Pigment Printing Machines. This innovative solution brings sustainability, speed, and cost effectiveness to the Indian textile industry. With the ability to print on all fabric types, including blends, while eliminating water intensive post-processing, the F Series is set to transform textile printing in India.

Apsom Technologies, a leader in digital textile printing solutions, has partnered with NKT (New King Time) to introduce the NKT F Series Pigment Printing Machines. This innovative solution brings sustainability, speed, and cost effectiveness to the Indian textile industry. With the ability to print on all fabric types, including blends, while eliminating water intensive post-processing, the F Series is set to transform textile printing in India.

NKT: A Global Digital Printing Innovator

Founded in 1993 and headquartered in Foshan Sanshui, China, NKT is renowned for its leadership in digital printing across ceramics, textiles, and industrial applications. The company operates on a 50,000 square-meter facility with nearly 300 employees, 60% of whom are technical engineers.

With a strong foothold in ceramic digital printing, NKT has established itself as the industry leader, holding an 80% market share in China. In India, its single-pass ceramic printers are widely used by leading tile manufacturers such as Kajaria Tiles. Leveraging its expertise in high-precision digital printing, NKT has now expanded into textile printing with the F Series, offering a state-of-the-art pigment printing solution.

The NKT F Series: Cutting-Edge Textile Printing Technology

The NKT F Series is designed to meet the evolving needs of the textile industry, offering unparalleled speed, precision, and customization options. One of its standout features is its customizable print head configuration, available in 16, 32, 48, and 64 Kyocera print heads, allowing businesses to scale production based on their requirements. With a high-speed performance of up to 2400m² per hour, the F Series ensures efficiency without compromising on quality. The machine is available in a 3.2m width, making it ideal for large-format textile printing applications.

Colour accuracy is another strength of the F Series, with the ability to print in 8-10 colours, ensuring vibrant and precise reproductions across a wide range of designs. The machine is powered by NeoStampa software, known for its user-friendly interface and advanced colour management capabilities. This makes it easier for manufacturers to streamline their workflow while achieving high-quality prints.

NKT FP19A: Advanced Paper Sublimation Printing

For polyester and synthetic fabrics, NKT’s FP19A paper sublimation printer provides a streamlined solution. Unlike pigment printing, sublimation requires pre-treated paper but eliminates post-processing like steaming or washing. The FP19A, with a width of 1900-2200 mm, offers configurations of 4 or 8 colours and 8 or 16 Kyocera heads, achieving a maximum printing capacity of 1150 m²/h in single-pass mode. A unique feature of sublimation printing is its ability to use vibrant fluorescent colour inks, allowing for striking and eye-catching designs.This advanced sublimation printer is particularly suited for sportswear, athleisure, and home textile industries, where vibrant prints and durability are essential.

Pigment Printing: A Game-Changer for the Industry

Unlike traditional reactive or sublimation printing, pigment printing offers several key advantages that make it a preferred choice for modern textile manufacturers. One of the most significant benefits is its compatibility with a wide range of fabrics, including blends, which expands its usability across different textile industries. Additionally, pigment printing eliminates the need for steaming or washing post printing, significantly reducing water and energy consumption. This not only lowers operational costs but also aligns with global sustainability goals. Its cost effectiveness and eco-friendly nature make it an attractive option for businesses looking to optimize resources while minimizing environmental impact.

Industries such as home furnishings, which often rely on blended fabrics, and shirting manufacturers, where durability and high-quality prints are essential, stand to benefit the most from pigment printing technology.

Apsom Technologies: Driving Innovation in India

Apsom Technologies has been at the forefront of introducing advanced printing solutions in India for over 30 years. With the launch of the NKT F Series, Apsom continues its mission of bringing cutting-edge technology to Indian manufacturers, enabling them to stay ahead in a competitive market.

The first NKT F Series machine is successfully running at Nirvan Silk Mills in Tarapur, Maharashtra

The first F Series machine has already been successfully installed at Nirvan Silk Mills in Tarapur, Maharashtra, where it has been running efficiently, showcasing its reliability and performance in a real-world production environment. Apsom not only facilitates the installation of the machine but also provides end-to-end support, including training and after-sales service, ensuring a seamless transition for businesses adopting this new technology.

For those interested in experiencing the capabilities of the F Series first-hand, Apsom offers live demonstrations at its Mumbai facility. This hands-on approach will allow potential buyers to witness the machine’s efficiency, precision, and sustainability benefits before making an investment. By providing access to the latest innovations in digital printing, Apsom is reinforcing its commitment to advancing the textile industry in India.

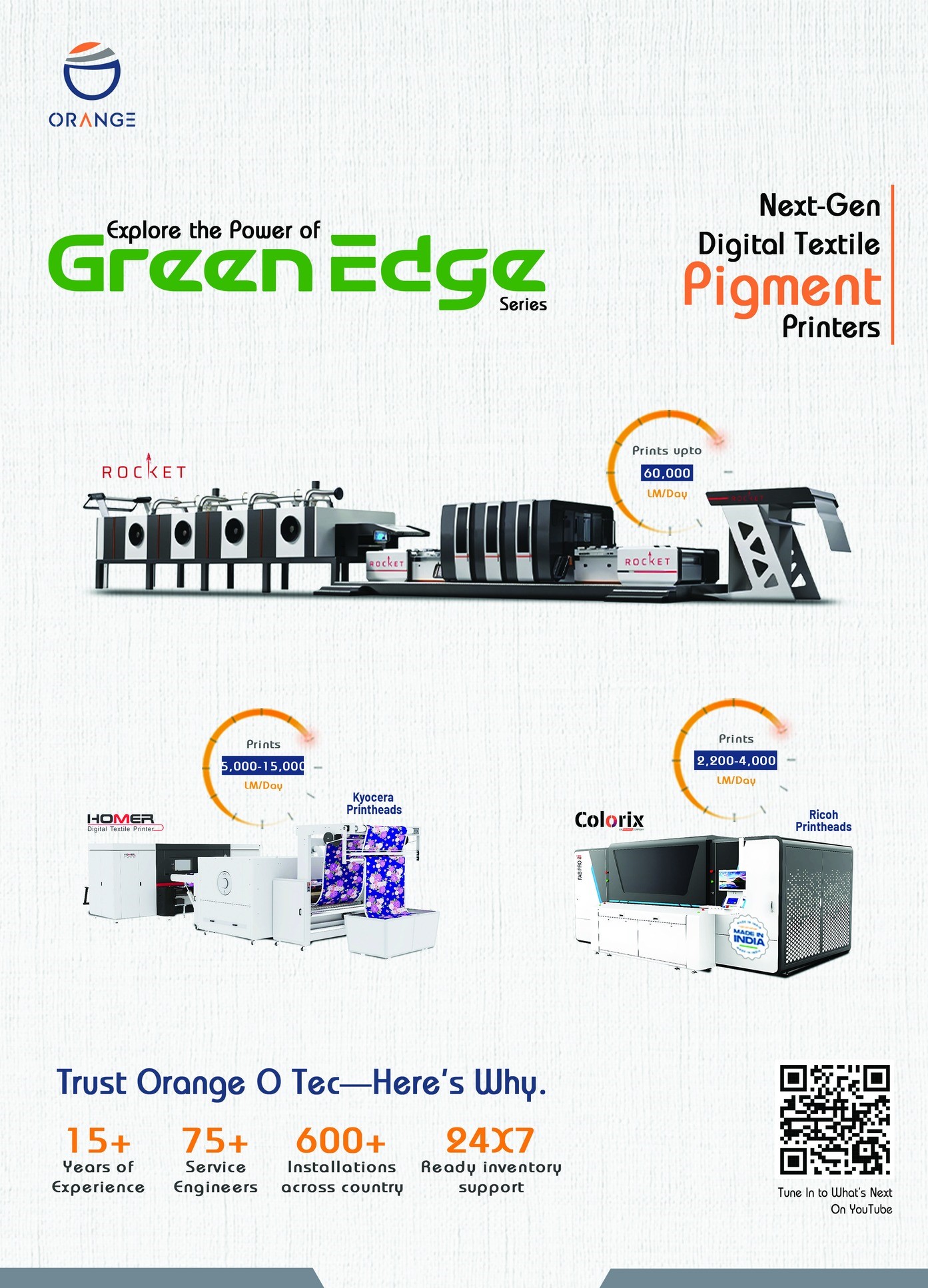

Pigment Solutions by Orange O Tec

With over 15 years of expertise and a dedicated team of 75+ engineers, Orange O Tec has solidified its position as a market leader in the textile industry. Headquartered in Surat, Gujarat, the company is at the forefront of digital textile printing, with 500+ installations across India. Orange O Tec’s advanced machines collectively print over 3.5 crore meters of fabric every month, showcasing their unmatched efficiency and industry presence.

Continuing this legacy of innovation, Orange O Tec is proud to unveil two new machines under the Homer range: Homer K24 and Homer K64. These state-of-the-art machines have been successfully installed in North and South India, setting new benchmarks in the pigment printing space.

Homer K24

A Game-Changer in Pigment Printing

The Homer K24 is an extraordinary machine that challenges the limitations of conventional pigment printing. Typically, in pigment printing, achieving depth and vibrancy requires multiple passes, which can significantly slow down production. However, the K24 is a game-changer. It delivers over 200 meters per hour at just 3 passes, compared to traditional 16-head machines, which manage only 130 meters per hour. This unparalleled efficiency allows businesses to produce vibrant, high-quality prints at record speeds.

In addition to its remarkable speed, the K24 offers exceptional value. With only a 15–20% higher cost than conventional 16-head machines, it provides an impressive 40–50% boost in production capacity, making it an ideal investment for textile manufacturers looking to enhance productivity without inflating costs. We now have more than 60 K24 machines running in India, serving different applications such as reactive, pigment, and disperse printing.

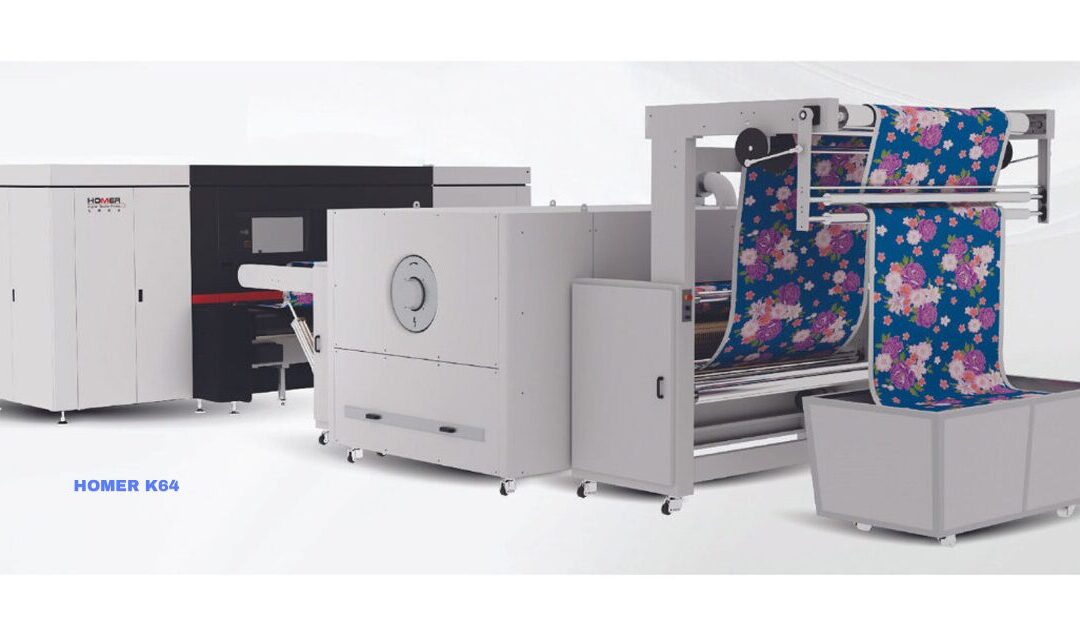

Homer K64

Homer K64

India’s Fastest Scanning Printer for High-Volume Production

The Homer K64 is designed to cater to high-volume printing demands with precision and speed. Capable of printing up to 15,000 meters per day, it is India’s fastest scanning printer. Equipped with cutting-edge features such as air blade drying technology, the K64 effectively eliminates moisture to prevent smudging and bleeding, ensuring flawless prints every time.

The K64 comes with Katana heads, enabling ink recirculation, which improves efficiency for pigment inks.

The machine is also equipped with an ink cooling system to enhance head performance.

A total of 12 K64 machines are currently running in India across various applications, including reactive, pigment, and disperse printing. By the end of March, more than 20 machines will be installed across the country.

The Rocket

Single-Pass Powerhouse

Homer is set to launch The Rocket, a single-pass machine with a staggering production capacity of 50,000 meters per day. Equipped with a rotary attachment, this innovation is poised to transform high-speed, high-volume production, offering manufacturers unmatched speed without compromising on quality.

Make in India

Make in India

Fabpro Series for Pigment Printing

Orange O Tec proudly unveils the Fabpro 1i and Fabpro 2i models, now available for pigment printing. Equipped with Ricoh heads (available in 8 and 16 configurations), the Fabpro series delivers unmatched precision, durability, and reliability. Built with world-class components, these machines stand tall against global competitors while offering competitive pricing to outperform Chinese alternatives.

With the Fabpro series, Orange O Tec reaffirms its commitment to empowering Indian manufacturers with cutting-edge technology for high-quality pigment printing solutions.

Trusted by the Best in the Industry

With over 225 Homer machines installed and a total of 550+ Orange O Tec machines running successfully across India, we take pride in being the backbone of the nation’s textile manufacturing sector. Our cutting edge technology, reliability, and commitment to excellence have made us a trusted partner for manufacturers looking to scale their operations and enhance productivity.

Join the growing community of businesses transforming their production with Orange O Tec’s world-class solutions, proudly supporting the Make in India initiative.

Orange O Tec Pvt Ltd Leading the way in textile innovation

Orange O Tec Pvt Ltd, based in Surat, Gujarat, is transforming the textile industry with its advanced digital and auxiliary textile machinery. With over 15 years of expertise and more than 500 installations across India, the company has built a solid reputation for offering innovative and high-performing machines.

Whether you’re an entrepreneur starting a new business or a veteran looking to boost productivity, Orange O Tec caters to all needs, providing machines that print anywhere from 1,000 meters to 50,000 meters of fabric per day. Their product range covers everything from entry-level machines to high-speed digital textile printers.

Supporting this robust offering is a dedicated team of more than 75 engineers, ensuring comprehensive after-sales service. This commitment has helped their installed machines achieve an output of 3.5 crore meters of fabric printed every month, a clear testament to their industry expertise.

The Homer K64: A Game-Changing Fabric Printer

One of Orange O Tec’s most innovative products is the Homer K64—a high-speed digital fabric printing machine that’s redefining the future of textile printing. It’s designed for businesses of all sizes, whether they are just starting or seeking to increase productivity and output.

The Homer K64 is currently the fastest scanning printer in India, capable of printing up to 15,000 meters per day. This machine has quickly become the go-to solution for high-volume fabric printing, offering speed, precision, and durability in one package.

Key features of the Homer K64

Unmatched Precision and Print Speed

The Homer K64 is equipped with industrial-grade piezoelectric printheads, offering multiple configurations from 32 to 64 heads. This flexibility allows the machine to print at high resolutions of 508-600 DPI, ensuring exceptional detail and vibrant color in every print. Its speed, coupled with high-quality output, makes it an ideal choice for businesses that need both precision and efficiency.

Advanced Air Blade Technology for Superior blanket drying

One of the standout features of the K64 is its air blade technology. The airblade in the Phoenix K64 textile printer removes moisture from the blanket, improving print quality by preventing smudging and color bleeding.

Ink Chilling and Misting Control

The K64’s ink management system is designed to maintain consistent ink temperature, ensuring color stability. The misting control system further enhances print clarity by reducing ink splatter, ensuring crisp, clean designs with minimal waste, making it particularly suitable for blotch printing.

Flexible Fabric Handling with a Longer Blanket

The Homer K64 is designed with a longer blanket, which improves the touch and feel of the fabric as it moves through the machine. This ensures smooth fabric feeding and controlled fabric movement, reducing the chance of errors during printing and allowing for a wider range of fabric types, including cotton, silk, polyester, and more.

Durability and Ease of Use

Despite its advanced capabilities, the K64 is designed with user-friendliness in mind. Its intuitive interface allows operators to manage the machine efficiently, even in high-pressure environments. Built for durability, the K64 is constructed with a focus on long-term performance, making it a reliable investment for businesses looking to enhance their productivity over the long run.

Replacing Traditional Flatbed Machines

With the Homer K64, Orange O Tec is paving the way for the replacement of older, traditional flatbed printing methods. The K64’s speed and flexibility far surpass that of flatbed machines, providing a faster and more efficient solution for fabric printing businesses.

A Growing Presence in India

As of now, more than 7 K64 machines are running successfully in India, with a target of 20 by March 2025, reflecting the increasing demand for this high speed scanning printer. Orange O Tec’s partnership with Homer has already resulted in more than 200 Homer machines running successfully across India, solidifying their strong presence and commitment to providing top-notch textile printing solutions. The K64 is not only leading the way in India but also making a significant impact globally, with over 50 machines installed worldwide.

Why choose the Homer K64?

For textile businesses looking for a powerful, efficient, and versatile printing solution, the Homer K64 offers all these benefits and more. Whether your business is focused on small-scale projects or high-volume production, the K64 delivers consistent, high-quality prints while enhancing overall productivity

Navigating Cyclical Trends in the Apparel Industry with Sustainable Textile Machinery

The performance of any industry follows a cyclical trend and apparel is not an exception. But there’s a point to be made: quality has become central. Thus, thinking about a quantum leap should be part of trends analysis. That implies many questions but notably one answer: looking forward, beyond current challenges—and focusing on the future of sustainable apparel industry technology.

When developing a new machine, it is mandatory to have a forward-looking approach as nothing can be done without it. Of course, it means thorough research, a deep knowledge of, in this case, apparel cyclical pattern, and eyes wide open to the market variables and on-trend forecasting. It’s a huge but necessary – and fascinating – job. Biancalani Textile Machinery has done it before and while developing all of their machinery, especially when developing AIRO®24 and AQUARIA®.

Both types of machinery had to be competitive in the apparel industry as per the perceived quality of the fabric, i.e. softness and how the fabric falls. Then, special fashion features had to be an added value to the fabric – cotton, viscose, and man-made ones. But it wasn’t enough. The old refrain of lowering production costs while improving product quality had to become a reality thanks to different steps that might not be immediately evident. Fabric uniformity is one of those steps. Wastewater disposal is another.

Fixing fabric flaws is a cost not to be underestimated. It is way easier to create an already qualitative product instead of having to fix it one, two, how many times to reach the desired outcome. AIRO®24 and AQUARIA® are a guarantee of flawless results when it comes to finishing a fabric, and that means cost and time savings.

Nowadays, investing in the appropriate technologies often means investing in technologies that make a process a green one, i.e. environmentally sustainable. Being sustainable would not have to be a burden on business. This brings us back to investing in the right technologies that make it possible to go green at comparable costs to those of “normal” – but let’s dare say “old” – productions. By reducing chemical fabric softeners, AIRO®24 both lowers production costs and improves fabric features, all of it certified by Clima Certified – Committed to low impact machinery.

Nowadays, investing in the appropriate technologies often means investing in technologies that make a process a green one, i.e. environmentally sustainable. Being sustainable would not have to be a burden on business. This brings us back to investing in the right technologies that make it possible to go green at comparable costs to those of “normal” – but let’s dare say “old” – productions. By reducing chemical fabric softeners, AIRO®24 both lowers production costs and improves fabric features, all of it certified by Clima Certified – Committed to low impact machinery.

Similarly, AQUARIA® transforms traditionally polluting treatments, such as bleaching, into green ones by saving precious water and reducing costs – one of those not immediately evident. In fact, apparel industry professionals know that water is paid for not one but three times: when you buy it, when you use it, and when you have to deal with wastewater disposal. Simply, AQUARIA® can solve both ecological and economic challenges, which is why it has been awarded Clima Certified – Committed to low impact machinery for textiles too.

While analyzing trends, it is useful to bear in mind one last thing: the greenwashing practice – as well as any other practice meant to deceive and to present products as better than what they are – does not pay in the long run. And as looking to the future is the answer, the only way of getting back up or staying on the cutting edge is to choose innovative, sustainable, competitive but, above all, reliable technologies.

GENEXT-Direct to garment printing launched by Perfect Textile Solutions

Perfect Textile Solutions recently launched the latest GENEXT brand direct to garment printing (DTG). It has revolutionised the apparel industry and updated the creation of graphics on clothing for the digital age. Now, instead of costly screen-printing, designers and manufacturers can create digital artwork and print it directly on a garment using a DTG machine.

Perfect Textile Solutions recently launched the latest GENEXT brand direct to garment printing (DTG). It has revolutionised the apparel industry and updated the creation of graphics on clothing for the digital age. Now, instead of costly screen-printing, designers and manufacturers can create digital artwork and print it directly on a garment using a DTG machine.

The DTG printing process isn’t much more involved than printing on paper—your design is sent from a computer to the DTG machine, and the printer does the rest. The machine uses an Epson digital piezoprinthead to print images directly onto garments. The DTG printing process makes them more easily affordable for small quantities.

In DTG printing, any array of vibrant colours can be used, and the process of printing a simple design isn’t any different than printing a complex, detailed graphic. DTG printing is even able to handle printing photographs on garments with crisp, clear results. This versatility can result in increased profits, with customers creating hats, bags, and other items to complement the t-shirts they order.

DTG pigment printing can print-on-demand, eliminating waste from unsold stock. Overproduction is endemic in the textile industry, but DTG printers help stop this. In addition, the inks used by DTG printers are water-based and eco-friendly, reducing your operation’s environmental footprint. DTG benefits the entire planet.

DTG printing makes it easy to create quality printed garments without having to hire a team of employees. The same person who takes the order can print the garments and prepare them for delivery.

Thanks to their RIP (Raster Image Processor), any major DTG system can print any picture from full graphic images to any type of vector.

DTG systems offer their customers different options to print over T-shirts (various sizes), shoes, hats, towels, and masks, and depending on your application, some companies also focus on developing customized applications needed.

It is worth mentioning that in low volumes, let’s say less than 100 shirts per model or design, DTG printing will have a lower cost of printing per unit than the traditional screen printing process.

Fewer costs involved in the process means more savings using this technology. The machine also comes with double-head printing to increase machine production.

Since this niche has been evolving consistently over the last ten years, the market offers different printer levels, from entry-level to industrial solutions. Moreover, this GENEXT DTG technology has seen an upward trend in consistency, quality, and high performance—the future for sure looks digital.

Thanks to its multiple applications in different kinds of textile garments (T-shirts, caps, shoes, bags, etc.) and other textile products like towels, pillowcases, and even canvas for art reproductions, it is one of the best printing technologies to expand your present business. To know more about the GENEXT DTG printer, you can contact shrikant@perfectextiles.com