Sewbots filling automation gap in garment manufacturing

Making clothes has always been a labour-intensive activity. The industrial revolution mechanised and automated textile production in the 18th century, whilst the invention of the sewing machine in the following century moved the bottleneck to the cutting room. Computer controlled cutting machines solved this problem, however, the task of assembling the garment is still mainly left to the manual labour.

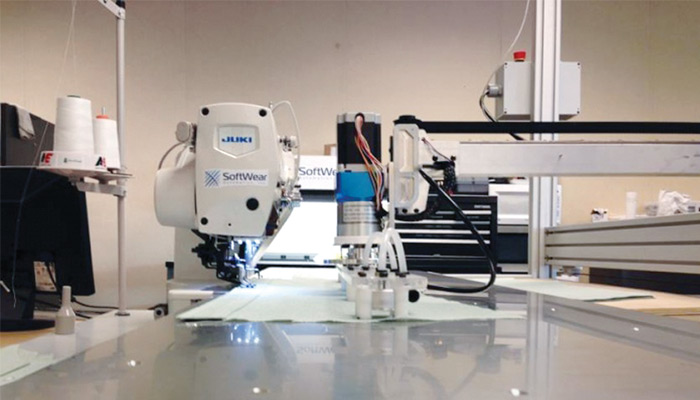

An Atlanta, US, based brand SoftWear Automation, launched in 2012, aims to change this by creating autonomous ‘sewn good’ worklines for home goods, footwear and automotive sectors. With its patented Sewbots fully automated technology, the company aims to geographically shorten the distance between manufacturer and consumer by utilising benefits of disruptive technologies.

In 2002, the Berry Amendment went into effect restricting the military from procuring clothing that was not made in the USA. Complying with the rule proved challenging due to a lack of skilled labour available in the US that only got worse as the current generation of seamstresses retired with no new talent to take their places. It was under these circumstances that the initial idea for Soft Wear was born and the company was launched in 2012,” explained Chairman and CEO Palaniswamy Rajan.

“Since then, we have grown our team to 25 engineers and developers, delivered our first products in the US and are currently working on moving from worklines for home goods to launching our first fully automated workline solely for apparel production.” The company initially received $1.75 mn grant from the defence department’s Defense Advanced Research Projects Agency (DARPA) to produce a prototype of its automatic sewing machine in 2012. After that, SoftWear received a $2 mn grant from the Walmart Foundation/Georgia Tech and a $3 mn Series A from CTW Venture Partners in 2014. SoftWear recently closed a $4.5 mn Series A1, ultimately rising just over $10 mn in the past five years.

The company’s Sewbots use a combination of patented high-speed computer vision and lightweight robotics to steer fabric to and through the needle with greater speed and accuracy than a human. Using Sewbot worklines customers are expected to be able to increase productivity while decreasing their overall defect rate. “They are also able to move their sewing closer to the end consumer or materials supply chain shortening lead times and reducing competitive pricing pressure without the need for chasing cheap labour all over the globe,” said Rajan.

“Most current automation in textiles and apparel is single operation specific — focused on automating a particular process— and still requires an operator to feed and manage the machine. Right now, we are seeing a strong desire to shift from this process focused automation to full automation, going from fabric roll to finished good with minimal human interaction. This shift will drastically transform how and where we manufacture giving brands and manufacturers to move closer to their customers or their materials supply chain.”

Currently, the company is developing a fully automated workline for T-shirts. “This line will go from cut piece to finished T-shirt without human intervention — save the machine operator managing our workline of course. When launched in the fourth quarter of 2018, this line will be capable of running 24/7/365 with a projected output of over 1 mn shirts per year,” explained Rajan.

Sewbo robot

Another US start-up, Sewbo, based in Seattle, WA, was founded by a web developer Jonathan Zornow, who also believes he can offer a solution that would not only produce garments of higher quality, but could also help bring garment manufacturing back to US. “Our technology will allow manufacturers to create higher-quality clothing at lower costs in less time than ever before,” said Jonathan Zornow, who invented the technology. “Avoiding labour issues and shortening supply chains will help reduce the complexity and headaches surrounding today’s intricate global supply network. And digital manufacturing will revolutionise fashion, even down to how we buy our clothes by allowing easy and affordable customisation for everyone.”

Despite widespread use in other industries, automation has made little progress in clothing manufacturing due to the difficulties robots face when trying to manipulate limp, flexible fabrics. Sewbo has addressed this issue by using a non-toxic polymer to temporarily stiffen fabrics, allowing the off-the-shelf industrial robots to build garments from a rigid cloth, just as if they were working with sheet metal.

The fabric panels can be moulded and welded before being permanently sewn together, and the water-soluble stiffener is removed at the end of the manufacturing process with a rinse in hot water. Patent-pending in 10 countries, the technology of temporarily stiffening fabrics can be used on a number of fabrics, including delicate materials, with the use of alternative low-impact treatments, except for impermeable materials, such as waterproof or coated fabrics, the manufacturer explains.

Assembling trousers for US military

Having secured several patents, which include the general concept of temporarily stiffened fabrics, as well as goods that have been assembled from the stiffened materials, and the method for applying the treatment and for manipulating the stiffened materials, Sewbo is now working towards commercialising its technology.

In October 2016, the company announced its plans to pilot its robotic process with Blue water Defense, a leading manufacturer of uniforms and equipage for the US Department of Defense. The company produces 8,000 pairs of combat trousers a day, half of which are made in a Puerto Rican factory that employs 500 people who sew garments together. “It requires 64 operations just to make a single combat trouser,” said CEO Eric Spackey. “If we can automate every two to three of those, it will make the process much more efficient.”

According to Sewbo, the company is now in the research and discussion stages. “The military requirements are as strict as they are extensive, so there’s a lot of work to make sure that this will be compatible with their needs,” commented Zornow.

New ARM Innovation Hub

This year, the Department of Defense awarded the 14th Manufacturing USA institute – the Advanced Robotics Manufacturing (ARM) Innovation Hub – to American Robotics. The eighth DoD-led institute, the ARM Institute joins the Manufacturing USA network in its collective effort to help revitalise American manufacturing and incentivise companies to invest in new technology development in the US.

Headquartered in Pittsburgh, PA, the winning consortium – comprised of State and local governments, industry, universities, community colleges, and non-profit organisations from across the country – contributed $173 mn, to be combined with $80 mn in federal funding. “The substantial cost matching reflects the importance the US robotics community places on this institute and its value to US businesses, academia, and State and Local Governments,” the organisation explained.

The ARM Institute joins the Manufacturing USA institute network, a programme with industry, academia, and government participants who co-invest in the development of cutting edge manufacturing technologies and capabilities.

Lectra Fashion PLM gears fashion companies up for fourth industrial revolution

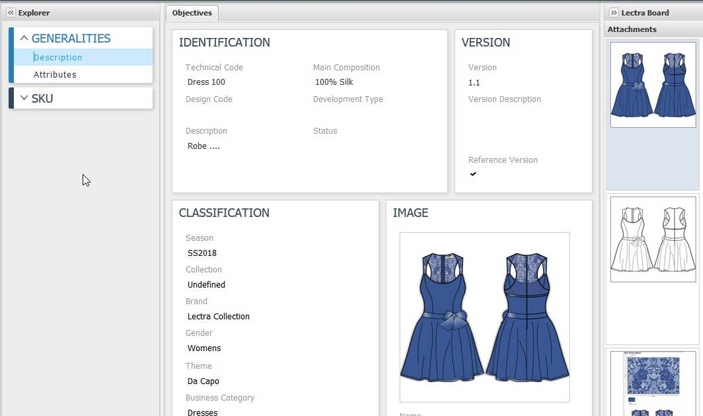

Lectra, the world leader in integrated technology solutions dedicated to industries using soft materials—fabrics, leather, technical textiles and composite materials— has announced the launch of Lectra Fashion PLM 4.0, the first-ever product lifecycle management solution designed to help fashion and apparel companies navigate the fourth industrial revolution and thrive in the digital era of fashion.

With digitalisation transforming the way consumers shop, today’s fashion companies are playing a neverending game of catch-up, as they compete for the attention of a generation of connected, fickle-minded millennial who want it all: Personalisation, sustainability, quality and speed, accessible at all times, across multiple channels, and at the lowest price. Industry 4.0 is not only revolutionising how manufacturers operate, but also how brands and retailers need to function, if they want to be fast and agile enough to meet the needs of this demanding new consumer.

The stakes are high and how effectively companies harness technology to put the consumer at the heart of their process will be the deciding factor in who comes out ahead and who gets left behind. Lectra Fashion PLM 4.0 has undergone a drastic reboot to give fashion and apparel companies the speed and agility they need to tackle the challenges of Industry 4.0 head on. Lectra Fashion PLM 4.0, with the widest functional scope on the market, acts as an intelligent nerve center to the digital supply chain, from planning through design to production. This ensures a consistent flow of error-free data between processes, technologies and people.

The system connects CAD, industry-standard software such as Adobe Illustrator, company IT systems (such as ERP) and external suppliers, so that actors across the supply chain can work on, save and share information on the platform, ensuring data integrity. The solution also draws on best practices, fashion-business intelligence and real world scenarios to automate administrative and repetitive tasks, with templates, standard libraries and shortcuts that allows more time for value-added activities. The final result is a fast, connected digital supply chain that helps fashion companies jump on trends quickly and deliver products that fulfill their customer’s expectations. This new incarnation of Lectra Fashion PLM is designed to work out of the box and can be scaled to accommodate the different needs of small to large businesses, brands, retailers and manufacturers. Companies can start small by implementing the standard offer, then add on as they go, choosing from up to ten different modules, such as design integration, product details, sourcing, sampling and costing.

The solution is available on a monthly subscription or perpetual license basis. Special attention has been paid to make this new product user-friendly, with learning tools that enable fast onboarding. The new Lectra Easy Tool allows IT teams to configure the platform to suit the needs of its users and the new mobile app, Lectra Collection Advanced, provides more ways to share information. The fuss-free implementation process means companies can get the platform up and running quickly with little disruption to business, and quickly start seeing a return on their investment. The only fashion dedicated PLM solution on the market that covers the entire value chain, Lectra Fashion PLM 4.0 is Lectra’s first software product release since it announced its 4.0 strategy, which aims to help fashion companies succeed in this brave new digital world.

The culmination of Lectra’s 40-plus years of experience in the fashion industry, the platform gives companies a competitive edge by giving them a smart, userfriendly solution that allows them to remain agile and connected, facilitating their transition towards Industry 4.0. “As our customers take their first steps toward the world of Industry 4.0, we want to be right there beside them to help them succeed. Just like today’s fashion companies, we are evolving to make our offer more customer-centric than ever before. We are extremely proud of this powerful new PLM platform, and are convinced that it will help our customers flourish in this digital age of fashion,” says Céline Choussy Bedouet, Chief Marketing and Communications Officer, Lectra.

SGGCI organises National Digital Textile Printing Conclave

With a view to meet today’s technological advancement and ongoing challenges of textile industry, it has become imperative to discuss and brainstorm on how India can match pace with its global counterparts in adopting global ideologies in the digital textile printing sector. India is one of the largest textile industries in the world. The market for digital printing technologies is moving out of the preliminary laps and gaining momentum in India. Especially Gujarat is poised to be a lucrative market for digital textile printing technologies. It presents huge business opportunity waiting to be harnessed and has the potential to grow exponentially in the coming years.

Considering the recent government initiative, focus areas like… Scope and need of digital textile printing, to encourage new entrepreneurs, supply of accessories for digital printing and trend of digital printing in fashion designing needs to be discussed by industry stakeholders. Besides that the prospective beneficiaries need to be aware of the Government of India’s Initiative announced in Union Budget 2017-18.

Keeping this backdrop in mind, The Southern Gujarat Chamber of Commerce & Industry organised a National Conclave on “Digital Textile Printing” on May 30, 2017 at Platinum Hall, Sarsana, Surat. It was a four hours conclave addressed by six experts of all areas of the topic like technology, inks, opportunities, investments, cost factors, potential market and commercial aspects. Besides, digitally printed garments were also showcased by students of the STERS (Surat Technical Education & Research Society).

Various presentations made during the event were “Future of Digital Printing Textile” by Neeraj Duggal Partner, Bluejade Texink Pvt. Ltd., “Brief about durst Italy & India and Italian Technology” by Dr. Rajiv Verma Managing Director, Durst Image Technology India Pvt. Ltd., “Digital Textile Printing – Pigment Printing” by Fabio Gromo, Sales Director, Durst Phototechnik AG Italy, “Brief about SACE Italy and Financial aspects of Digital Printing Textile” by Sandeep Babbar, Head of Mumbai Office, International Network SACE SpA, “Green Technology in Textile / Difference between Traditional Printing and Digital Printing” by Bijoy Roy Marketing Director, Orange O Tec Pvt.Ltd., “Importance of Digital Printing Textile in Fashion Industry” by Subas Dhawan Chairman Gokul Tex Print, Current trends in “Digital Textile Printing in India” by Aditya Chandavarkar Partner, CNT Expositions and Services LLP, and “Digital Printing -Today and Tomorrow” by Parimal Vakhariya Director Dream Digital.

Overall, it was a very interactive event, attended by more than 500 delegates including leading textile industrialists, leading official and chief operating officers of various textile companies, leading finance & project consultants, corporate decision makers, industrialists/investors from South Gujarat, Firms who source textile products from Gujarat. During the Conclave the SGCCI also organised a concurrent show to showcase the latest digital printing technologies and related services.

Dürkopp Adler automatic sewing equipments

Since its foundation in 1860 in Bielefeld (Germany), Dürkopp Adler AG has developed to become one of the world’s technology leaders in the field of industrial sewing equipment. The group operates with a worldwide service and distribution network of 11 subsidiaries and more than 80 authorised dealers. The objective of the company is to perfect the automation of production procedures, guaranteeing at the same time a maximum degree of flexible applications.

Optimised work station for setting sleeves with touch screen (650-10 OP7000)

Sleeve setting is one of the most difficult sewing operations in the clothing industry. The demands on the operator with regard to dexterity and knowledge of production Technology are extremely high. When using the sleeve setter 650-16 a large part of the difficult handling is taken over by the machine by means of the “curve support” function. Sewing is simplified considerably, the training periods are shortened essentially, and performance as well as quality are increased.

Product specifications

- Function “curve-support“ for easier handling specially in the sleeve head

- Finest fullness nuances via step motor-controlled belt transport to handle sleeve fullness even in most difficult fabrics

- Programmable fullness values from -6 to +16

- Ergonomically designed work station for fatigue-free working with LED sewing light directly in the sewing area and optimal view on the material to be processed

- Short training times due to easiest operation

CNC-controlled pattern stitcher for medium-heavy duty applications (911-210-6055)

911-210-6055 – High application flexibility combined with M-TYPE sewing technology. The wide spectrum of applications in the field of reproduciblesafety seams and functional seams as well as decorative stitching in technical textiles, car interior decoration, garments and leather goods makes special demands on the operating means. The pattern stitcher 911 with its new and innovative design and the flexible material clamp technology is predestinated for these tasks. The approved M-TYPE sewing technology and the intuitive user software guarantee an excellent sewing result, maximum functionality and high productivity.

Product specifications:

- Flexible use by “teach-in programming” directly at the touch screen control panel or by means of external PC programming software

- High bobbin thread capacity by XXL vertical hook (Ø 32 mm)

- Low maintenance due to approved M-TYPE technology

- High performance due to max. sewing speed of 2.000 stitches/min

- Programming of “input/output signals” for every single stitch possible

- Constant, tight stitch formation by electronic thread tension, programmable per stitch

- Electromagnetic thread clamping device for neat seam beginning

- Thread breakage identification with automatic sewing stop

Eurolaser produces innovative laser systems

eurolaser GmbH designs, develops and produces innovative laser systems for material machining in industry and craftwork. With a multiplicity of potential uses, the Lüneburgbased company has established a position showing the way ahead for new and established laser applications in many sectors of industry and belongs to the world’s leading manufacturers of automatic laser cutting machines.

Laser Cutter XL-3200

The CO2 laser machine XL-3200 with a processing area of 2,270 x 3,200 mm (89.4″ x 126″) is the largest model of the XL series. The huge dimensions allow the processing of big-size acrylic plates. The high acceleration of the optical head releasing the laser beam assures best efficiency even on this table size.

Laser Cutter L-3200

By using this machine, wood can perfectly be cut and engraved. This CO2 laser machine is one of the largest among the eurolaser series and is available with many optional features. An ideal machine size for all applications requiring plenty of space. Laser power: 60 to 600 watt.

Laser Cutter M-800 + Shuttle

The laser cutting system M-800 is well-prepared for all applications in the fields of laser cutting of foils and membrane switches. A special feature is the optional shuttle table system which almost doubles your productivity, enabling you to hold all the aces even with a “smaller” laser cutting system. Type of laser: CO2 laser; Processing area: 1,330 mm x 750 mm; Laser power: 60 to 400 watt.

Crea Solution presents latest softwares for fashion industry

Crea Solution is an Italian leader company specialised in providing software, services and IT consulting services that provides solutions exclusively dedicated to fashion, luxury goods and soft materials industry both in production & sales areas with 2D, 3D CAD CAM technologies, Made to Measure, PLM, and in RETAIL with solutions for Visual Merchandising and E-Commerce.

Create™ the pattern making suite & 3D design

Create™ is the new generation 2D CAD system to create and modify pattern models and is deeply integrated with our 3D CAD to get efficiency in the whole production process.

Create™

It is an innovative software that improves and simplifies pattern model creation. Create™ eases the designer’s every day work with intuitive features and tools that speed up the design process in a fast and more efficient way. Simplifies internal features like notches, buttons and drill holes. Provided with Expander©, a fast tool for pattern size grading. Provided with a wide range of convertor in order to communicate with other CAD and export to plotters and cutters.

Lotta™ + V Stitcher ™

This revolutionary software transform 2D pattern model into realistic 3D clothes. It allows a reduction of time to market by 30 per cent, it boosts the production by 40 per cent cutting down prototyping and gives efficiency to all the production process.

Creafit™ integrated made to measure automation? Now it’s possible

Creafit™ is actually the best automate solution to realise MTM garments. Creafit™ takes in charge a MTM Garment in the whole Value Chain: From order to delivery. Creafit™ is easy integrated with e-commerce or company portals. The order will be collect in a powerful DB, that sends it automatically to all the company network: Sales area (CRM), management area (ERP), from logistic to storage (MRP), Pattern Area (CAD), where will be independently processed, modifying the style, and generate markers by materials and fabric characteristics: plain fabric, stripe, plaid in automatic way applying quality rules. The platform is now ready for cutting process, where with the support of accurate and efficient system to read fabric placed on the Zund-Crea bridge machine, will be possible to detect the normal bow and replace the pieces before the cutting. Actually the time for the complete process, except cutting, is around 2 minutes for each garment using Creafit™ Solution.

Match™ Print or Cut stripe or patterned fabric fully Automatic

Match™ a complete autovision suite for your different plaid, stripe and printed fabric. If you use Printed Fabric you can redesign your design process from cad to nesting; Do you need to be perfect positioning of your pattern pieces on printed fabric? You can find a complete suite of tool included on Create™ and Clichè™ and you can quickly and easily determine where each piece of a style pattern should be placed on the printed fabric to achieve the desired effect in the finished garment. If you have also plaid and stripe fabric inside in our tools you have many instruments for positioning your pattern perfectly.

After that you can cut this printed fabric, patterned, motive printed, plaid or by stripe. When you need to cut exactly are by far not regular in the cause of a fabric roll. Distortion can run straight line to a curve; the repeat size of pattern varies within the roll. The nesting needs information of the actual status of the pattern with its distortions and irregularities. Manually or with the actual systems you have many losing situation such as; time of production, unreadable load-fabric, pre-operation, finishing operation after cut, many people involved, low productivity.