A-S-S Automated Sewing Systems

The A-S-S Automated-Sewing-Systems AG is a specialist for machine construction since its foundation in 2000. What was started with a serging machine grew in the meantime to a portfolio of more than 20 sewing machines for jackets an trousers. By well elaborated and functional process- optimised solutions as well as the highest demands to processing and material, ASS has developed to an internationally successful company.

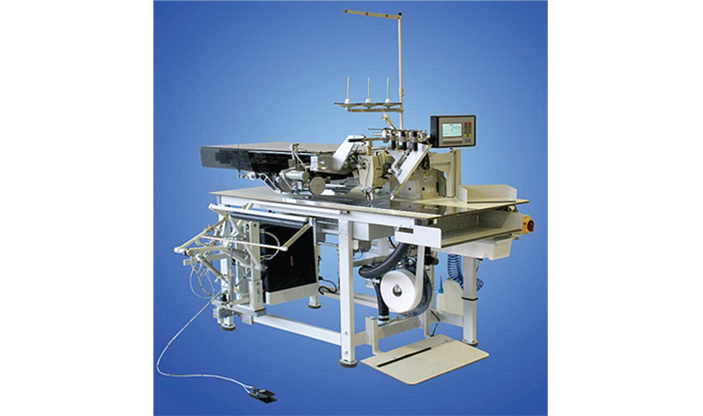

BASS 3203 universal automatic welt pocket unit

The BASS 3302 is a universal automatic welt pocket unit. This unit can sew all kinds of common welt pockets: straight, slanted, with or without flap. Sewing witz zipper can be integrated without any problem. BASS 3302 sew at a high speed. Clamp transfer and all trimming systems of the sewing unit have their own drive; clamp transfer and corner cutting are controlled fully automatically by step motors. The center knife is driven separately by an electric motor.

- Freely programmable control with a memory of 40 seams

- Pocket length from 20 to 200 mm, optional up to 240 mm

- Needle gauge from 8 mm to 30 mm in steps of 2 mm available

- Stitch length, sewing speed and transfer speed can be programmed individually

- Each pocket seam can be programmed with true back tack or condensed stitches

- Automatic flap sensing by photocell

- Three separate programmable laser beam marking lights for precise and easy loading

BASS 5800 sewing unit for trouser manufacturing

The BASS 5800 sewing unit is designed for small to medium-sized trouser manufacturing companies. It is possible both to sew pocket facing to pocket pouches, and to lap fell the left and right fly pieces to front trouser parts. The operation of the workplace is possible after a very short training period. The machine functions are marked with graphic symbols with additional display of the corresponding parameters in the respective language.

- Freely programmable control unit

- Sewing of pocket facings in all sizes

- Individual stitch length programming

- Optional programming of condensed stitches or back-tacking stitches

- Automatic scanning of the seam length

- Stacking unit

A.M.P. PISANI presents wide range of machines

For more than seven decades, AMP Pisani has been designing and manufacturing quality machinery for apparel and textile industries as well as for roll slitting applications and customised projects. AMP Pisani’s machinery is exclusively manufactured at its facility in Italy by a skilled team of mechanics, electricians and software engineers who are able to design and manufacture customized units.

T520 automatic roll slitter

Numerically controlled automatic roll slitter for rolls with max diameter 30cm (12″) and length 73″. Machine available also for larger rolls. The unit can slit most of fabric in rolls (bias or straight cut), non woven (with or without adhesive) and synthetics. With special devices machine can slit even polyethylene and PVC rolls, carbonium fibres, paper rolls, masking tapes, roofing materials, insulating tapes with foam and other materials.

Totally closed machine. Highly safe for the operator, no diffusion of cutting dust and less noise. Automatic cut with high speed positioning of the blade carriage with worms crew and brushless motor. Blade penetration speed in the roll adjustable on continuous rate with worms crew movement and brushless motor. Photocell to detect the diameter of the roll. Up to 6 cutting widths with the programmable number of cuts for each automatic cycle. Cutting speed up to 9 cuts/min. Machine can also easily be operated manually. Up to 50 different cutting cycles with all the cutting parameters can be stored and retrieved in the machine memory Adjustable blade rotation speed (up to 600 RPM) and adjustable roll rotation speed (up to 400 RPM) with digital vectorial inverter. Possibility to select the roll rotation direction. Automatic sharpening of the circular knife (both sides) with adjustable sharpening time after a programmable number of cuts. Blade speed will be set automatically to the optimal sharpening speed during sharpening. Self-centering pneumatic chuck with grippers to lock the roll on the cardboard and on its external surface. Machine standard equipped with non-rotating roll shaft. Rotating shaft and expanding rotating shaft on request available with extra cost. Pneumatic system to lift and support the roll shaft for easier loading/unloading operations. Laser system to measure the blade diameter with automatic adjustment of stop position near the roll shaft. No knob to adjust the forward travel end of the blade carriage. Automatic positioning of the blade at the edge of the roll and automatic return of the blade to the initial position of the automatic cycle PLC controlled machine with HMI Interface.

P92 Molding machine for bra cups in fabric

The machine P92 is a flexible unit with two molds than can mold different types of materials (cotton, elastomeric fabrics, micro fibres, multi-layer fabrics) including pre-cut pieces (i.e cups with the shape to be sewn on the bra, no need of die cutting after molding) and in some cases even the finished garment (post-molding).

- The machine consists of two molding areas where the pieces are loaded/unloaded on a cold disk that can be changed depending on the size.

- The operator positions the pieces on the loading/ unloading stations then starts the molding cycle and waits until they are molded.

- The molding cycle consists of the descent from the top of a heated bell to keep uniform the temperature around the fabric and then a heated mold moves upwards for molding the cup. This exclusive system reduces the molding time even to 25 sec or less. Once the cycle is finished, the operator removes the molded cups and positions the new material. A simple adjustment enables the position of the mold in the heated bell to get the requested height of the cup.

- All setting of temperature (up to 250 °C) and times are adjustable with digital timers and thermoregulatory. Machine equipped with PLC.

Speciality industrial sewing machines by AMF Reece

AMF Reece CR, s.r.o. is a world-wide manufacture of specialty industrial sewing machines such as mechanical and electronic eyelet buttonhole machines, chainstitch machines, decorative handstitching machines, button stitching and wrapping machines, autojig machines and trouser sewing units including pocket welting machines.

ES-505 Angel Indexer – Electronic eyelet buttonhole machine

Excellent traditional buttonhole quality and terrific productivity now completed with an indexing unit capable of angle buttonhole sewing, especially suitable for real sleeve buttonhole sewing. The ES- 505 Indexer machine is specially designed for sewing multiple buttonholes on jacket sleeves and jeans fly fronts at required distances between each buttonhole. The indexer unit ensures that buttonholes are sewn automatically one after another at required lengths distances that are set by the operator on the touch screen display. The new angle model allows sewing of slanted buttonholes with angle up to 45 degrees. Structural design of the indexer unit, placed behind the clamp feet, ensures easy access to the looper is if needed. The indexer unit does not need to be disassembled when taking off the clamp plates for easy maintenance.

- Currently the fastest machine available, running at 2,700 spm

- New modular design of the sewing head with integrated sewing motor

- New patented balancing and sewing drive mechanism

- Incorporated round LED lights

- No need of mechanical adjustments when changing the stitch bite

- New vertical cutting system instead of standard lever cutting

- Independent thread tension of all threads

- High resolution full-colour touch screen display

- Pneumatic system controls

- 6 buttonhole combinations in 50 programmes

RA-3700 Ultrasonic ribbon loop attacher

The AMF Reece RA-3700 is the most productive automation of attaching ribbon loops on garments. The continuous form satin ribbon is cut, folded, and sewn on the garment in an automatic sequence generating cost savings while ensuring consistent quality.

- Selection of loop length from control panel

- Ultrasonic cutting eliminating stains and dark spots

- Electronic detection and warning of splice and joints

- Step motor driven loop measurement system for accurate length sizing

- Direct drive sewing head

- Touchscreen control panel

TH-5500 Automatic bottom hemming machine

Automatic bottom hemmer unit provides an overlapping method increasing productivity while ensuring accurately sewn hems without operator interference. It is ideal for use on jeans, casual trousers and skirts.

TH-5500 benefits:

- Accurate start and finish of sewing in relation to side and felled seams by photocell provides exact positioning of hem joint

- It is up to 3 times more productive compared to traditional methods

- It eliminates twisted legs or ropy hems

- Overlapping of hem joint start and finish seam can be programmed from control panel

- No more puckered hem stitches especially after washing

- The machine features easy adjustment of hem folding width from single knob, independently servo driven top and bottom pullers ensuring pucker-free sewing on all types of fabric, patented hem guide system ensuring consistent hem width, independent dual presser foot system providing optimum fabric holding and consistent seam allowance, adjustable stitch length from control panel, direct-drive servo sewing head for best results on heavy fabrics, individual right and left hem programming from coloured touchscreen control panel, self compensating right fabric tension mechanism, individual pressure adjustment for fabric tensioners, easy adjustment of fabric huide for different hem diameters, extra large hook (3 times larger than standard).

Wilcom develops new EmbroideryStudio e4

In the four years since the release of EmbroideryStudio, Wilcom has been meeting with embroidery specialists in order to better address their individual needs. Among its results, Wilcom developed its new advanced integrated Design Library and its EMB design file. These tools will not only improve productivity and enhance the number of orders, but do this with increased accuracy.

Automatically indexes all designs

Managing hundreds or thousands of client designs is time consuming and often leads to lost design files, resulting in having to redo the work. The new advanced integrated Design Library automatically indexes all designs on a computer or network, allowing users to search for a design in seconds by customer, order, date or any other text field. Recently viewed designs can be retrieved and opened in two clicks. Designs can also be grouped and sorted by customer, order, date, folder, design status, stitch count and more. Designs can also be opened, converted, printed and stitched in a batch, saving the users from repeatedly doing the same tasks.

Creative abstract office business technology communication internet concept: Modern professional desktop computer PC workstation with blank screen or empty monitor, keyboard and mouse isolated on white background.

Productivity tool

Functionality has been increased by the latest Wilcom. EMB design file, which allows all the job information to be stored effortlessly together with the design. This means there is no need for a separate database, since the garment, quantities, sizes, colours and approval status can all be identified in one place.

Open a design file and you will also find the customer and contact details, order number, order and due dates, general notes and more. Everything is also indexed and searchable within the Design Library, making this an extremely powerful productivity tool. Real-life TrueView representations of designs can be displayed on high-resolution images in the actual colours the customer orders.

The enhanced auto-digitizing provides nearaccurate stitch counts, too, allowing quotes to be rapidly generated. Approval sheets can then be e-mailed directly to customers for fast approvals. Both of these features are available in EmbroideryStudio e4 Designing and Decorating. Hereby, all the usual frustrations around design, orders and approval management are removed, resulting in an uncomplicated and easy-to-use multi-decorating solution.

ITMA 2019 enhances index of products to facilitate collaboration and sourcing

Exhibition space application for ITMA 2019, the world’s largest textile and garment technology exhibition, opened recently. The exhibition, which has been held every four years since 1951, showcases the entire textile and garment making manufacturing chain, as well as raw materials. As the most established industry exhibition, ITMA’s Owner, CEMATEX – the European Committee of Textile Machinery Manufacturers – constantly reviews its index of products to ensure its relevance and continuously improve visitor experience.

Fritz P. Mayer, President of CEMATEX, explained, “A core value of ITMA is to be relevant to the textile and garment making industry and end-users. As such, we are always exploring new ways to reinvent and to make our platform vital to all stakeholders by offering an integrated sourcing experience. More importantly, during every ITMA, manufacturers are able to have meaningful discussions with their partners and customers on innovative ideas that offer users a competitive advantage.

At ITMA 2011 a new fibre and yarn sector was introduced, and this was favourably received by visitors who could source their raw materials at the show. Due to the favourable response received from fibre and yarn exhibitors and visitors at the last two ITMA shows, ITMA 2019 will include woven, nonwoven and knitted fabrics in the fibre and yarn exhibit sector. In addition, digital and screen printing inks have been classified in the printing chapter. This will allow ink producers to be in the same hall as printing machinery manufacturers so that visitors can easily source technology and consumables. A new service introduced for the benefit of machinery buyers is leasing and financing services, according to ITMA Services, the organiser of ITMA 2019.

A. E. Roberts, Managing Director of ITMA Services, commented, “We have taken a comprehensive approach in ensuring the index of products will be extremely useful to manufacturers as the global business environment remains challenging. The launch of ITMA 2019 space application has been eagerly awaited by textile machinery manufacturers and raw material producers. We have received a lot of enquiries from past exhibitors and interested manufacturers who have not taken part in ITMA before. This augurs well for ITMA 2019 and the industry can look forward to another strong industry platform.”

Han Bekke, President of International Apparel Federation said, “ITMA is a very established textile machinery exhibition but over the years, the exhibition show profile has evolved in keeping with industry trends and challenges. It now features the entire textile and garment making production chain, including raw materials.

“Hence, our IAF members which represent the world’s leading brands and apparel makers find it an excellent sourcing platform. As we look for innovative solutions to offer consumers exciting products made in a sustainable way, we are glad to be able to explore new materials and technologies in one location at ITMA 2019.”

ITMA 2019 will be held from 20 to 26 June at Fira de Barcelona, Gran Via venue. Jordi Galtés, President of AMEC AMTEX, the Spanish Association of Textile Machinery Manufacturers, enthused: “We are excited to be hosting ITMA again. Participants had a good experience in 2011 and we hope to replicate it again in 2019. Spain is home to some of the most famous luxury and fast fashion brands and an interesting destination for all in the textile, garment and fashion industry.”

The last ITMA exhibition, held in Milan in 2015, featured exhibits from the entire textile and garment making value chain spread over 108,268 square metres of net exhibition space. It drew the participation of 1,691 exhibitors from 46 countries and visitorship of almost 123,000 from 147 countries.

Shipments of new textile machinery in 2016 vary between segments

Shipments of long-staple spindles and open-end rotors were up, while those of short-staple spindles were down. Shipments of draw-texturing spindles and circular-knitting machines decreased, while those ofshuttle-less looms and electronic flat knitting machines increased.

Deliveries of new long-staple spindles and open-end rotors soared by nearly 111 per cent and 66 per cent, respectively from 2015 to 2016. The number of shipped short-staple spindles decreased in 2016 by 12 per cent compared to the previous year. The number of shipped draw-texturing spindles fell by 14 per cent and shipments for new circular knitting machines by 3 per cent year-on-year. In contrast, deliveries of electronic flat knitting machines soared by 99 per cent in 2016. In the segment of finishing machines (fabrics continuous), the number of stenters increased in 2016 year-on-year by 22 per cent.

These are the main results of the 39th annual International Textile Machinery Shipment Statistics (ITMSS) just released by the International Textile Manufacturers Federation (ITMF). The report covers six segments of textile machinery, namely spinning, draw texturing, weaving, large circular knitting, flat knitting and finishing. The 2016 survey has been compiled in cooperation with more than 140 textile machinery manufacturers, representing a comprehensive measure of world production. This number does not include the numerous Chinese companies that are represented by the so called “District”. Therefore, the amount of participating companies is likely to be around 200.

Spinning machinery

Shipments of new short-staple spindles fell by nearly 12 per cent year-on-year in 2016, the third decrease in a row. The level of short staple spindles declined to about 7.9 mn spindles, the lowest level since 2009. Most of the new short staple spindles (92 per cent) were shipped to Asia, whereby shipments fell by 12 per cent year-on-year. Thereby China, the world’s largest investor of short-staple spindles, experienced an increase of 9 per cent, whereas deliveries to Bangladesh, Indonesia and Vietnam rose by 97 per cent, 4 per cent and 31 per cent, respectively. The six largest investors in short-staple spindles in 2016 where China followed by India, Bangladesh, Vietnam, Turkey and Pakistan.

Global shipments of long-staple (wool) spindles soared by 111 per cent from around 54,000 in 2015 to nearly 114,000 in 2016. Deliveries to Turkey, one of the main investors in long-staple spindles in the last few years, jumped by 153 per cent from just around 11,000 in 2015 to around 27,800 spindles in 2016. The majority of long-staple spindles (60 per cent) were shipped to Europe (including Turkey). Nearly 39 per cent of long-staple spindles had Asia as destination.

Shipments of open-end rotors rose by 66 per cent to a level over 634,000 rotors in 2016. About 92 per cent of worldwide shipments of open-end rotors were destined for Asia. Thereby, deliveries to Asia increased strongly by over 87 per cent to nearly 583,000 rotors. Shipments to China, the world’s largest investor in openend rotors, increased its investments significantly by around 92 per cent in 2016. In contrast, regions such as North America and South America recorded annual percentage declines of 72 per cent and 53 per cent, respectively. The world’s second and third largest investors in 2016 were India and Turkey.

Shipments to China, the world’s largest investor in open-end rotors, increased its investments significantly by around 92 per cent in 2016. In contrast, regions such as North America and South America recorded annual percentage declines of 72 per cent and 53 per cent, respectively. The world’s second and third largest investors in 2016were India and Turkey.

Weaving machinery

In 2016, worldwide shipments of shuttle-less looms increased by 4 per cent to 84,700 units. Thereby, shipments of air-jet and water-jet shuttle-less looms increased by 15 per cent (to 22,900) and by 6 per cent (to 31,800), respectively. In contrast, rapier/projectile shuttle-less looms decreased by 6 per cent to around 30,000 units. Not surprisingly, the main destination of shipments of all shuttleless looms (air-jet, water-jet and rapier/projectile) in 2016 was Asia with 91 per cent of worldwide deliveries, of which 41 per cent were water-jet looms and 32 per cent rapier/projectile looms. In Europe and North America 73 per cent and 56 per cent of shipments were for rapier/projectile looms, while the share of waterjet looms was only 2 per cent and 7 per cent, respectively.

Finishing machinery

The 2016 edition of ITMF’s International Textile Machinery Shipments Statistics included for the eleventh time also data on finishing machinery. However, the categories were revised in 2015. In the segment fabrics continuous shipments of some machine types increased in 2016 like dyeinglines (CPB), sanforizing/compacting machines or stenters. In contrast, shipments of washing machines (stand-alone), bleaching-lines, mercerizinglines and relax drying/tumbling machines decreased. In the segment fabrics discontinuous shipments of air-jet dyeing and jigger/beam dyeing machines fell, whereas those of overflow dyeing machines rose