AI Embroidery Machines (i-TM) by Tajima

Since development of the multi-head embroidery machine in 1964, Tajima Group has transformed the previously expensive embroidery into a more accessible commodity, bringing colors to people’s lives all over the world. We are developing decorative embroidery, which has been used mainly in the apparel industry, into functional embroidery and expanding its possibilities into interior, automotive, aerospace and space applications. We have also acquired a Canadian software company to the group, in order to establish an organization capable of providing both hardware and software solutions to changing market needs and manufacturing site issues.

Since development of the multi-head embroidery machine in 1964, Tajima Group has transformed the previously expensive embroidery into a more accessible commodity, bringing colors to people’s lives all over the world. We are developing decorative embroidery, which has been used mainly in the apparel industry, into functional embroidery and expanding its possibilities into interior, automotive, aerospace and space applications. We have also acquired a Canadian software company to the group, in order to establish an organization capable of providing both hardware and software solutions to changing market needs and manufacturing site issues.

TMEZ-KC Series – Automated optimization of embroidery quality by i-TM

The industry’s first technology “i-TM” (Automatic Upper Thread Tension Adjustment) is now available on the multi-head cylinder-type machine that can be applied to ready-made products.

It is about i-TM that provides optimal tension adjustment.

• Reduction of adjustment time:

• It takes time to adjust the thread tension: Thread tension adjustment is easy (unnecessary).

• Uneven of result by operator

• There is an uneven of result by operator’s skills: Eliminate quality defects due to skills and new operators are also active

Cap embroidery enhanced in pursuit of higher productivity. Reinforcement of the cap frame support structure has contributed to stabilization of the embroidery finish, by dramatically increasing the maximum rotation speed up to 1,000 rpm.

• Cylinder Type

• Needles: 9,12, or 15 needles

• Embroidery Space: 450x360mm embroidery field (4-head, 6 head or 8 head model)

• Embroidery Space: 450x500mm embroidery field (2-head, 4-head, 6 head or 8 head model

TMEZ-SC Series

TMEZ-SC Series

Features

• “Picker free” trimming system – The new improved “Picker Free” ATH system is able to stabilize trimming and enhance production efficiency.

• Besides that, it is much easier to replace a bobbin without the picker in the way

• DCP-Digitally Controlled Presser Foot- The height of the pressor foot can be randomly set according to the material thickness on the operation panel

• The fabric does not flutter even when using hard-to-embroider materials like leather, thick fabric, stretchy fabric and quilting

• 12.1 inch TFT Touch Monitor

Specifications

• Needles 15

• Factory options: Position Marker, LED lamp

• Dealer options: Stand, Stand Tray, Border Frame, Cap Frame2

• Revolution: Max. 1,200

• Electricity: Single-phase 100-120V, 200-240V, 50Hz/60Hz

Shirt Finisher and Fusing Machine by VEIT Group

For over 60 years, the requirements and the problems of our customers world-wide have been our most important challenge. For decades, worldfamous brands in the German and the international garment industry have had confidence in the innovative, high-quality products and services of the VEIT Group. Our experts consult with you as a partner to assist you in finding the best solution for your project no matter if you are planning to use individual

For over 60 years, the requirements and the problems of our customers world-wide have been our most important challenge. For decades, worldfamous brands in the German and the international garment industry have had confidence in the innovative, high-quality products and services of the VEIT Group. Our experts consult with you as a partner to assist you in finding the best solution for your project no matter if you are planning to use individual

machines or if you need a complete production line.

Shirt Finisher SF 27

Maximum energy-saving – Astounding performance

With the new SF 27 model, VEIT has succeeded in significantly reducing energy consumption, increasing the quality of the finished shirt and optimising the ergonomics of the Shirt Finisher.

Unique benefits:

• High quality finishes without touch-up

• 3 dimensional adjustable sleeve tensioners for the perfect result

• Heat/energy recovery gives additional cost savings and faster payback

• Moisture control for shortest drying times

• Minimal heat and noise emissions provide a pleasant working environment

Energy efficiency

• Optimised heat recovery through new extraction concept

• Optimised air and steam flow for maximum steam savings

Technical highlights

• Optimised tensioning system

• Same footprint with or without heat recovery system

• Reduced noise

• Industry 4.0 standard – enables monitoring of current production

User-friendliness

User-friendliness

• Simple process flow

• Short training period for new employees

• Optimised ergonomics

With the temperature control and the pressure system, the two fusing parameters temperature and pressure can be maintained at a constant level over the entire width of the machine. The Contactless Belt Control CBC eliminates belt edge wear and tear through contact-free belt detection. Easy touchscreen operating and a thoroughly conceived, easyaccess service concept adds to the perfect package.

• Optimal adjustment of pressure system (soft, medium) and heating sequence (top, bottom) to the materials to be processed

• Lowest possible energy consumption

• Consistent fusing quality due to optimized cleaning of the belts both on the inner and the outer side. Consequently, major reduction in soiling of roller and fusing material

• Prevention of faulty fusing through start/stop function in the event of a diversion from pre-set fusing parameters

• Easy operating with new 7″ colour touch display

Embroidery Studio by Wilcom

Wilcom is a leading provider of innovative, quality embroidery software solutions worldwide. In 1979 Wilcom’s founders shared a vision for automating the embroidery industry that changed the way people create and produce embroidered goods. A global organization headquartered in Sydney, Australia, Wilcom leads the industry with ongoing innovations that push the boundaries of creativity in personalized expressions and apparel decoration. With a reputation for excellence, Wilcom has become the world’s favourite embroidery software for quality, productivity, ease-of-use and service.

Wilcom is a leading provider of innovative, quality embroidery software solutions worldwide. In 1979 Wilcom’s founders shared a vision for automating the embroidery industry that changed the way people create and produce embroidered goods. A global organization headquartered in Sydney, Australia, Wilcom leads the industry with ongoing innovations that push the boundaries of creativity in personalized expressions and apparel decoration. With a reputation for excellence, Wilcom has become the world’s favourite embroidery software for quality, productivity, ease-of-use and service.

EmbroideryStudio Digital Edition Designing

The ultimate embroidery & multi-decoration software for professional digitizers, embroidery shops, industry trainers and educators, and apparel decorators. CorelDRAW® Graphics Suite is included, fully integrated and provides full vector and bitmap graphics software for multi-decoration, printing, cutting, engraving and more. Read more about CorelDRAW®.

As customer demands continue to evolve, Wilcom understands the importance of adaptability. Today, we’re excited to unveil EmbroideryStudio Digital Edition, a gamechanging new release. With its array of new features, flexible payment options, and seamless multi-device access, this software is designed to empower our customers to work wherever they work best. EmbroideryStudio Digital Edition is available for convenient download and activation. Enjoy hassle-free access to your software!

EmbroideryStudio Digital Edition Decorating

Professional embroidery & multi-decoration software for custom embroidery shops and apparel decorators expanding into embroidery.CorelDRAW® Graphics Suite is included, fully integrated and provides full vector and bitmap graphics software for

multi-decoration, printing, cutting, engraving and more. Read more about CorelDRAW®.

EmbroideryStudio e4.5 Decorating is the new standard for custom embroidery shops and apparel decorators expanding into embroidery. With a simple graphics digitizing approach, full control of lettering and stitch settings, and over 200 professional embroidery fonts, you can produce your own commercial embroidery designs more quickly and easily than ever before.\

EmbroideryStudio e4.5 includes a new software component called Embroidery Hub. Manage all your Embroidery Connect WiFi Devices in one place to help you run your embroidery business more efficiently. This is a huge time and money-saver.

Automatic Pocket Setter and Feed of the Arm Unit by SIP-ITALY

SIP-ITALY is specialized in the development and production of automatic units for Jeans & Trousers. Our passionate team has more than 30 years working experience in this field. Our plant is located in Verona, north of Italy. We focus on “A top class” apparel industries, interested in the best product of engineering, quality and daily productivity output. We achieve the goal to manufacture friendly use automatic work-stations, with best ratio in terms of productivity and versatility at the lowest running cost. Most of our automatic workstations are equipped with common electronic hardware and standard sewing heads. It is the best technical solution, giving incredible benefits to our users.

SIP-ITALY is specialized in the development and production of automatic units for Jeans & Trousers. Our passionate team has more than 30 years working experience in this field. Our plant is located in Verona, north of Italy. We focus on “A top class” apparel industries, interested in the best product of engineering, quality and daily productivity output. We achieve the goal to manufacture friendly use automatic work-stations, with best ratio in terms of productivity and versatility at the lowest running cost. Most of our automatic workstations are equipped with common electronic hardware and standard sewing heads. It is the best technical solution, giving incredible benefits to our users.

PS342-FG1SIP.V2 -Fully Automatic Programmable Pocket Setter unit for jeans & pants upgrade with cold plastic folding group

Automatic workstation for pocket folding and attaching in one operation. User doesn’t need to utilize any pocket creaser unit. The unit can be upgraded into two sewing head configuration.

Highligths:

• Folding and attaching on the same workstation;

• Cold folding device is the unique solution for stretch denim fabric;

• No extra workers and helpers to manage the pocket pressing unit, with saving of area, energy and generally reduction of the running cost;

• Original Brother sewing head, standard X-Y technology, hardware & software by Brother Japan, same as other Brother units;

• Local pocket jig production by user in all countries of the world;

• Automatic device for quick pocket jig change;

• Friendly use, no skill operator and helpers required;

• Digital sewing thread tension;

• Presser foot height controlled by step motor, editing sewing programme;

• Large-capacity memory capable of storing bulky data, up to 512 programs, 500,000 stitches;

• Multicolor touch screen 5.6” programmed for multi languages;

• All standard pneumatic valves and cylinders by SMC;

• Lowest running cost. Freedom to outsource the standard consumable spare part in all market locally at the best price and delivery

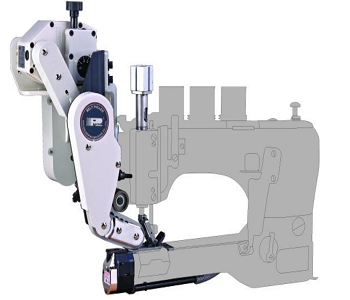

9280SPV – Feed of the Arm Unit

9280SPV – Feed of the Arm Unit

Feed of the arm unit, 3 needles, chain stitch, special design for lap felling and/or double-lap seaming like yoke sewing, back seat, in-seam and side-seam operations for jeans, casual trousers in general, working clothes, denim jackets, etc.

Highligths:

• Direct Drive Electronic Puller, transmission by Step Motor, ensures a perfect synchronization with the sewing head;

• Perfect timing means no waves in the seam, no puckering, perfect stitch quality!;

• Sensor detecting the thickness: the work-station automatically adjusts the pressure on the presser foot bar along the seam in order to avoid to skip stitch or un-constant stitch length;

• Automatic dynamic speed control on thick area;

• Automatic dynamic presser foot edge device controlled by thickness sensor for constant seam margin on crotch – back rise area;

• Automatic pneumatic chain cutter controlled by photocell;

• Common electronic servomotor as other units of Sip-Italy range;

• Sewing head made by Brother Japan;

• Dynamic take up lever for attractive balloon stitches even with thick sewing threads;

• Full pushbutton operation. The stitch length can be changed simply by pressing a button and changing the parameter on the console. Very easy setting!;

• Reverse lap folder made in Italy;

• Standard consumable parts, available in all markets with lowest running cost

Cutting Room Equipment by Serkon

The Spirit of Serkon lives on at Six Storeys, 10.000 square meters. A High Tech Technology Facility with storeys of 1250 sqm Each Europe’s biggest producer in cutting room equipment. We produce technology for Cutting Rooms Made in Turkey and we export it more than 70 countries worldwide. Serkon is the Leading and sole manufacturer of CNC Cutters in Turkey. Besides CNC Cutters, Serkon has wide range of spreaders, exclusive tables, conveyor

The Spirit of Serkon lives on at Six Storeys, 10.000 square meters. A High Tech Technology Facility with storeys of 1250 sqm Each Europe’s biggest producer in cutting room equipment. We produce technology for Cutting Rooms Made in Turkey and we export it more than 70 countries worldwide. Serkon is the Leading and sole manufacturer of CNC Cutters in Turkey. Besides CNC Cutters, Serkon has wide range of spreaders, exclusive tables, conveyor

systems, CAD System, and inspection machines.

Continue Cutter DCC90

A conveyorized cutting table efficiently moves material from the spreading table to the cutter and then moves cut parts onto the bundling area.

• Application Range: Industries that handle textiles (e.g. garments, upholstery)

• Material Use: Woven (Denim), Knitted Fabrics

• Fabric Width: 000 cm

• Cutting Window: 180 cm

• Cutting Height: Cutting height up to 90 mm compressed. [Marker height may vary depending on fabric type and gsm]

• Cutting Mode: Continue Cutting

• Machine Speed: 80 mt/min max

• Knife: Intelligent Knife System

Process and Functions:

Process and Functions:

• All-In-One desktop

• Compatible with all CAD Systems

• Monitoring of all parameters on display

• Files can be controlled on display before cutting

• Possible cutting sequence change for optimization

• Selecting patterns which are not to be cut before starting and bypass them during cutting

• Detecting the crosness of the spreaded fabric by laser and cutting it with the same cross angle. (Crosswise Displacable)

• Possibility to manage, convert and transform all kind of notches (normal, V notch and fly notch).

• When patterns do not fit within marker, operator may change the scale of patterns

• Operator may adjust the bite length

• Easily stores cutting setup files for quick retrieval to accelerate future cut jobs.

• If preferred the knife does not pass through the cutted adjacent lines twice (no overcut)

• Blade monitoring system observes the abrasion of the blade and stops the machine automatically when It needs to be replaced

• Ability to change the Radius of patterns at corners

• Resume cutting by Hibernation if it is being disturbed

• Able to increase efficiency by adjusting speed ramps up/down according to fabric type

• Different Cutting Options (Crosswise Cutting, One Way Cutting, Mixed Cutting, Symmetry Cutting, Tubular Cutting, Clockwise/Anticlockwise Cutting)

• Intelligent Reporting System. Delivering hard data for analysing cutter activity and production. Graphical report is also included

• Virtual intelligent knife

• Marker edit page

• File Cutting options (Single File/Multiple File/Parallel File)

• Maintenance Page

Fully Automatic Fabric Spreading Machine – Mini Master[MN3]

MN2 Mini Master allows spreading of full range of available fabrics: from very delicate, thin, elastic and difficult to spread, to thick, heavy fabrics like denim. Thanks to the servo motor driven fabric and main motors, It provides more precious and dynamic spreading. The machine is equipped with a cradle with belt feeding, double solid PVC belt (not parallel stripes), which guarantees perfect and even grip throughout the fabric width. Electronically controlled “dancer bar” and encoder are available for “tension free” spreading. The machine is equipped with user friendly Industrial PC 10.5 inch Touch Screen Display in where all marker information is available. Intelligent Reporting System is delivering hard data for analyzing spreader activity and production. Graphical report is also included. Optionally allows operator to see the patterns through the projector.

Computerized Metering Device and Belt Type Puller by Racing

Racing Sewing Machine Co., Ltd. was founded in 1980’s. And we have been developing a new products almost every year in order to satisfy with customer’s request. Racing’s main goal is that customer always likes to take Racing’s device as first thinking to solve the sewing problems. Now its products are 100% made in Taiwan and its parts are 90% from local Taiwan and other 10% from other high advanced countries. Also Taiwan is famous for semiconductor industrial. Racing takes this advantage to do R & D for manufacture its computerized product with very reasonable cost and excellent quality.

Racing Sewing Machine Co., Ltd. was founded in 1980’s. And we have been developing a new products almost every year in order to satisfy with customer’s request. Racing’s main goal is that customer always likes to take Racing’s device as first thinking to solve the sewing problems. Now its products are 100% made in Taiwan and its parts are 90% from local Taiwan and other 10% from other high advanced countries. Also Taiwan is famous for semiconductor industrial. Racing takes this advantage to do R & D for manufacture its computerized product with very reasonable cost and excellent quality.

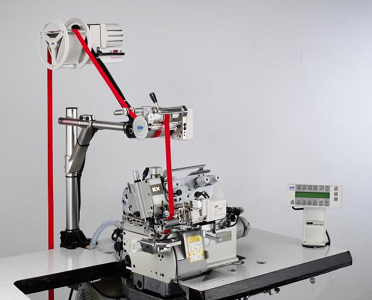

MCU 30 – Computerized Metering Device

• Tension type computerized metering device for precise tension.

• Auto cutting and re-insert function suitable for any elastic attaching sewing.

• Ideally for connecting the circular sewing.

• During the sewing operation, it can auto cut the tape fast in front of the presser foot for covering sewing to make the flat and beautiful joint.

• 26 programs, 8 tensions are available for each program (Max. 208 tensions are available after combination)

Versatile Tension type computerized metering device (The main unit is separated from the control box and display panel)

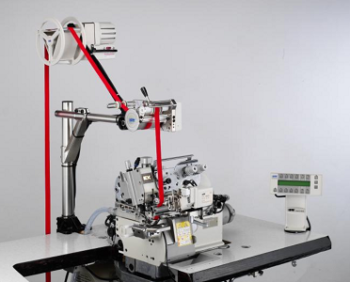

PF-UB/EFV/AF Belt Type Puller for Extra Heavy Duty

PF-UB/EFV/AF Belt Type Puller for Extra Heavy Duty

Description:

• Electronic chain cutter

• ECV: Feed-off-the-Arm

• EFV: Flat Seamer

• Pneumatic Guillotine Cutter

• GFV-8: Cutter Width Max. 8mm

• GFV-16: Cutter Width Max. 16mm for diving Suit

• AF: Pneumatic presser foot

Specification:

• Adaptable Machine: Feed-Off-Arm

• Driven Way: Upper Roller

• Transmission Type: P-2

• Min. Distance between Roller and Needle: 32 Mm

• Belt Type (*Regular): 210xl17

• Puller Length: 0.3~4.5 Mm

• Sewing Max. Speed (Continuous/Intermittent): 3000/4500

• Power; Ac 100~240v