Sewing Unit and Ultrasonic Welding Machine by PFAFF Industrial

Excellent product know-how and continuous innovation – this is what the traditional trademark PFAFF from Kaiserslautern has been known for since 1862. As one of the technology leaders PFAFF INDUSTRIAL produces state-of-the-art solutions for the processing of textile materials (technical and nontechnical) and leather. PFAFF INDUSTRIAL is the only provider of sewing- and welding solutions with different welding methods worldwide. This unique competence is also underlined by the company slogan ”Excellence in seaming“.

Excellent product know-how and continuous innovation – this is what the traditional trademark PFAFF from Kaiserslautern has been known for since 1862. As one of the technology leaders PFAFF INDUSTRIAL produces state-of-the-art solutions for the processing of textile materials (technical and nontechnical) and leather. PFAFF INDUSTRIAL is the only provider of sewing- and welding solutions with different welding methods worldwide. This unique competence is also underlined by the company slogan ”Excellence in seaming“.

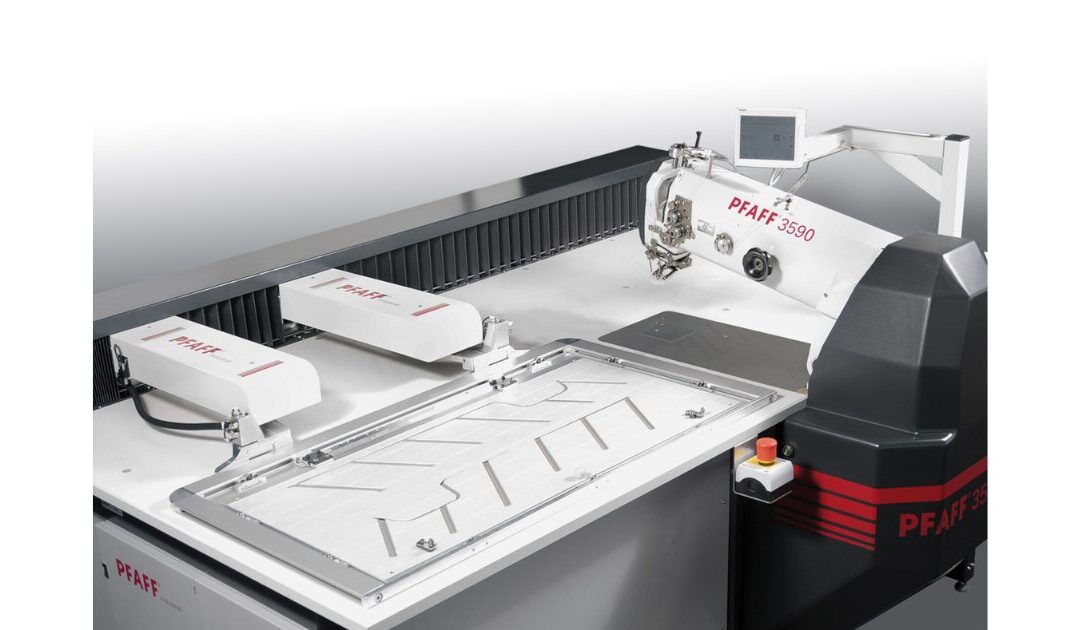

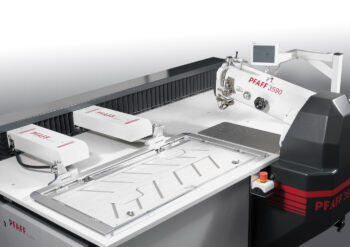

PFAFF 3590/3690 VARIO – Programmable large area sewing unit

Features

• Special automatic sewing head suitable for threads from 80/3 to 11/3 with raisable arm (90 mm clearance)

• Vibrating presser with programmable height control (two positions) – floating presser foot on request

• Excellent multi-directional sewing properties due to vertical hook system

• Accurate seam quality due to the intermittent feed (feed stop when needle enters material), shifting of the material in the work clamp is avoided and wear on the hook is reduced

• Touch-control-panel P1 with integrated SD card reader. The P1 guarantees an intuitive operation

• Sewing programs + software changes can be entered via SD card

• In combination with the programming system “PSP“ the 3590 series is the last link in a dataaided upper stitching program. Existing CAD data sets can be used with “PSP“ to create sewing and cutting programs

• The simplicity of the work clamps design enables the technician to manufacture the inserts (sewing jigs) on site

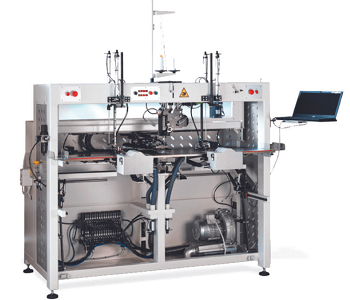

PFAFF 8311 – New Ultrasonic Welding Machine with continuous welding force monitoring

PFAFF 8311 – New Ultrasonic Welding Machine with continuous welding force monitoring

With the new 8311, PFAFF INDUSTRIAL introduces a new generation of ultrasonic welding machines. With more than 30 years’ experience in rotary ultrasonic welding, the engineers at PFAFF have successfully developed this process even further. In addition to the regulation of speed and welding energy, the new 8311 allows the force measured during welding to be measured and kept constant – a true world first and a quantum leap in textile ultrasonic welding. Adjusting and handling the machine becomes much easier. The process becomes clearer, more reproducible and easier to understand. In short, the machine is taken to a new level.

Features

• Unrivaled attribute: Continuous welding force monitoring!

• ALL welding parameter are measured and regulated “speed, energy AND force”

• Innovative dual roller system: Cutting wheel can be activated by motor

• New: Versatile platform for various options:

• motorized puller

• simple parallel puller

• lighting from above and below (for lower ply visualization)

• seam cooling device (from above and below)

• cross mark laser for precise start position

• Smart functions: Seam end detection, ply detection (e.g. cross seams)

• New touch screen (simple handling with user-friendly icons)

• All proven features of existing ultrasonic machines are included in the new machine concept

• Option: motor-driven puller

Pocket and Sleeve Placket Setter’s by M.A.I.C.A.

M.A.I.C.A. Italia is, with more than 20 different machines, the only manufacturer who can propose a complete automated line for shirts; going from pressing machines to fully automated sewing systems. Our 40 years of experience make M.A.I.C.A. Italia the best partner when it comes to the automation of your shirt lines. Our patented machines are unique and will give you the satisfaction of the Made In Italy products. Full of creativity, M.A.I.C.A. Italia will continue to innovate in order to bring to the market technology and quality.

M.A.I.C.A. Italia is, with more than 20 different machines, the only manufacturer who can propose a complete automated line for shirts; going from pressing machines to fully automated sewing systems. Our 40 years of experience make M.A.I.C.A. Italia the best partner when it comes to the automation of your shirt lines. Our patented machines are unique and will give you the satisfaction of the Made In Italy products. Full of creativity, M.A.I.C.A. Italia will continue to innovate in order to bring to the market technology and quality.

UAM 01: Pocket Setter

The automated unit UAM 01 with its patented MAICA sewing head was created to attach the pocket, which does not need to be pre-ironed. The speed of the machine can be used for big productions, but can be adapted to small productions as well.The lasers help the operator to perfectly place and align the fabric. A vacuum system, along with blades, will fold it to make it ready for the stitching part. The flexibility of the machine also allows sewing labels and collar bones. Furthermore, a new application allows the machine to sew the task with its flap at the same time. Thanks to a 35 x 35cm area, this unit is the perfect solution for working clothes tasks attachments. The program containing all the shapes and pockets data can be changed directly on the machine, which is controlled by the computer. This option allows us to act directly from Italy if a problem is detected, using only the Wi- Fi. The cost of the jigs and its easy changeability makes this unit very flexible.

UAM 04: Sleeve Placket Setter

UAM 04: Sleeve Placket Setter

• This machine is a unique fully automated system that allows folding and sewing the sleeve plackets to the sleeves without them needing to be preironed

• It is equipped with two patented MAICA sewing heads – right and left side – which allow to prepare the next piece while the machine is sewing the current one

• The laser helps the operator to perfectly place and align striped fabrics. A vacuum system, along with blades, will fold it to make it ready for the stitching part

• The length of the sleeve placket can be adjusted using the same jigs, but different widths will make you change it for a new one. The width can go from 15mm to 30mm

• Two stackers will follow the process and move the finished pieces to the back of the unit

• Everything is controlled by the computer so that the operator only needs to feed the machine

• This option allows us to act directly from Italy if a problem is detected using only the Wi-Fi.

Cutting Machine and Spreader by OROX GROUP

OROX GROUP is an Italian company that operates in the field of high technology, applied to the cut of materials and advanced technology services. We develop innovative projects integrating precision mechanics with the most advanced electronic and government software thanks to the professionalism and to a long experience. We create partnerships for the supply of equipment and services in the field of automated cutting, proposing, with a courageous choice for the industry, as a partner to companies that already operate in the sector with its products. We offer concrete alternative to continue to be competitive due to the implications of global competition from low-wage countries. We guarantee that you have direct control of production processes and the proper management of the cost of the finished product, thanks to investments in automation.

OROX GROUP is an Italian company that operates in the field of high technology, applied to the cut of materials and advanced technology services. We develop innovative projects integrating precision mechanics with the most advanced electronic and government software thanks to the professionalism and to a long experience. We create partnerships for the supply of equipment and services in the field of automated cutting, proposing, with a courageous choice for the industry, as a partner to companies that already operate in the sector with its products. We offer concrete alternative to continue to be competitive due to the implications of global competition from low-wage countries. We guarantee that you have direct control of production processes and the proper management of the cost of the finished product, thanks to investments in automation.

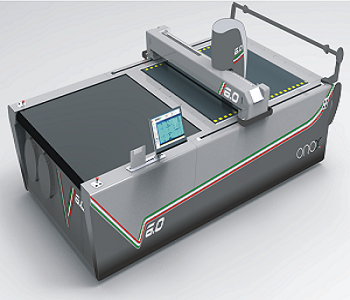

V CUT – Cutting Machine

New Cutting Machine made by OROX Group. VCUT is the OROX® solution designed and developed for medium/high productions. The innovative technologies and quality materials build in the VCUT system, grant a high quality and high performance in the cutting production, reducing manpower costs, waste of raw materials, and eliminate the human mistakes in the cutting room. The several patents in our cutting solutions, combined with cutting-edge hardware-software tools, allow ourcustomers to get competitive advantages and benefits in their production.

The software V-CUT with its algorithms, ensures top performances in the cutting production, combining features such as «continuous cutting» system, «zero gap» between the pieces, cut files optimization and advanced management of cutting strategies in the single pieces or in the whole marker.

VCUT technology can be integrated and interfaced with the other tools in the cutting room, in order to create a single data management platform and achieve the goals to speed up and remove the mistakes in the production process.

VCUT technology can be integrated and interfaced with the other tools in the cutting room, in order to create a single data management platform and achieve the goals to speed up and remove the mistakes in the production process.

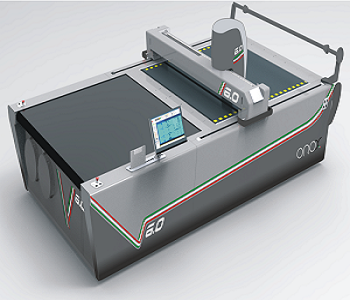

VRun – 4.0 Spreader

VRUN the new OROX fabric spreading machine, the culmination of our extensive experience and development in the textile industry, useful for any field: clothing, furniture, technical fabrics, medical, automotive etc. This advanced machine represents the pinnacle of current technology, offering distinctive features of reliability, speed, precision, and ease of use.

Constructed with high-quality materials and equipped with cutting-edge technology, our fabric spreading machine ensures reliable and continuous operation, minimizing downtime.

iSpread – iSpread Pro (4.0 industry)

The ISpread family software is especially developed to optimize the spreading operations, avoiding waste of materials and paper, making them completely automatic and integrated with the company management system.

Macpi’s Tunnel Finisher and Belt Fusing Machine

Macpi, founded in 1961, is a worlwide leader in manufacturing highly technological machines for garment industry following the tradition of Made in Italy with a constant research in terms of quality, style and innovation that cannot make compromises with a downward policy. The accured experience of almost 60 years brought Macpi to produce greatly sophisticated automatic units for thermo- fusing, loading and unloading system, complete line for the intermediate and final finishing of jackets, coats, jeans, knitwear, trousers, shirts, automatic machines for stitch-free applications and special units for industrial laundries. The headquarter located in Palazzolo s/O, Brescia province, is a state of the art facility where R&D, production and offices are combined, the production site in Vigevano is dedicate to tables, dummies and boilers for garment and laundry industries, Shanghai company is the main reference for the Asian market.

Macpi, founded in 1961, is a worlwide leader in manufacturing highly technological machines for garment industry following the tradition of Made in Italy with a constant research in terms of quality, style and innovation that cannot make compromises with a downward policy. The accured experience of almost 60 years brought Macpi to produce greatly sophisticated automatic units for thermo- fusing, loading and unloading system, complete line for the intermediate and final finishing of jackets, coats, jeans, knitwear, trousers, shirts, automatic machines for stitch-free applications and special units for industrial laundries. The headquarter located in Palazzolo s/O, Brescia province, is a state of the art facility where R&D, production and offices are combined, the production site in Vigevano is dedicate to tables, dummies and boilers for garment and laundry industries, Shanghai company is the main reference for the Asian market.

341.00 – Continuous Belt Fusing Machine

Features:

• Cold loading belt with inverter control

• Length 1100 mm

• Fusing heated area with no.2 cylinders drive

• Length 1000 mm

• Unloading belt with inverter control

• Length 1060 mm

• The machine is already adapted to be connected with the automatic loader Mod. 985 and unloader Mod. 978

• Useful working area: 1000 mm

• 7″ color terminal TCW for parameters setting complete with USB port and Wi-Fi connection. It is also adapted to control by video the loding and unloding devices

• Automatic switch off

• Fusing pressure from 0 to 6 Ate with 2 cylinders

• Programmable belt speed from 2 to 10 mt/min and controlled by inverter

• No.2 programmable temperature controls

• Automatic light signal of “machine ready” or any eventual malfunctioning

• Four belts cleaning devices, two inner and two outer

• Detachment of fused fabric by carbon blade

HEATING the machine heating is by steam only. The max. temperature which can be achieved on the fabric is 10°C lower than the steam nominal temperature

534 – Tunnel Finisher

534 – Tunnel Finisher

Continuous module-type tunnel for garments finishing. In function of its composition and the type of work to do, it can produce from 500 to 800 pieces per hour. the tunnel is composed and complete with:

• An automatic right load station for single garments complete with gamrents lack signal; and an unload station

• Variable-speed chain conveyor (controlled by an inverter) with hooks spaced out at 317 mm. intervals

• One steaming chamber

• One variable-temperature ventilation chamber and variable capacity through inverter

• Steaming quantity regulation

• Steaming humidity adjustment

• Garments falling signal

• Pillows for steam containment in the steaming chamber

• Programming and regulation with TCW “7 programmer:

• Short or long garments with independent controllow steaming

• Continuous or alternate garments loading

• Variable and programmable garments transportspeed

• Partial and totalizer garment counter

• Variable extractor for extra steam canalization(inverter)

• Registration up to 99 programs

Cutting and spreading machine’s by MorganTecnica

MorganTecnica is an Italian Company founded in 2008, on the initiative of Fabrizio and Federica Giachetti with the collaboration of their father Franco. As a result of a continuous exceptional growth, today it’s a multinational group of companies, successfully operating everywhere in the world, while proudly keeping the R&D and entire production “Made in Italy”. In 16 years of history, MorganTecnica has faced new challenges to become a reference point in the apparel Industry and in the furniture and automotive sectors. Today we can claim to have the largest range of machinery and software solutions for the cutting room. We produce several types of roll loading and handling systems, automatic spreaders, spreading tables, labellers, automatic cutters with different lay thickness – single ply and multilevel.

MorganTecnica is an Italian Company founded in 2008, on the initiative of Fabrizio and Federica Giachetti with the collaboration of their father Franco. As a result of a continuous exceptional growth, today it’s a multinational group of companies, successfully operating everywhere in the world, while proudly keeping the R&D and entire production “Made in Italy”. In 16 years of history, MorganTecnica has faced new challenges to become a reference point in the apparel Industry and in the furniture and automotive sectors. Today we can claim to have the largest range of machinery and software solutions for the cutting room. We produce several types of roll loading and handling systems, automatic spreaders, spreading tables, labellers, automatic cutters with different lay thickness – single ply and multilevel.

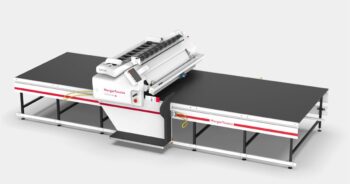

NEXT 2 70 DENIM

• Next 2 70 Denim is MorganTecnica’s newest highply cutting machine specifically designed to ensure maximum reliability in terms of endurance and performance in the cutting process of hard fabrics, such as denim fabric.

• Several mechanical devices have been implemented in this machine to strengthen the head, the plate and the use of a blade with increased 3 mm thickness.

• Artificial Intelligence allows the best self-handling of processes such as sharpening cycles or real time speed control.

• This automatic cutter is also able to self-detect any operating anomaly through its auto-diagnosis system and drastically reduce machine breaks and stops.

• The Next 2 70 Denim technology guarantees the highest cutting quality combined with maximum productivity, low running costs and fast ROI

Performance:

Performance:

• Max. cutting thickness: 7 cm compressed

• Max. cutting speed: 65 m/min

• Max. cutting acceleration: 8 m/s2

• Max. positioning speed: 120 m/min

• Max. positioning acceleration: 10 m/s2

• Effective cutting window length: 170 cm

• Effective cutting window width: 180 – 220 cm

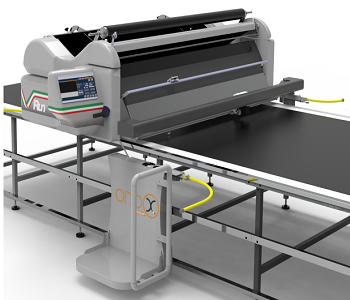

FOX 2 80 PRO – Spreading Machines

• The new Fox 2 80 PRO has everything that the most demanding customer can desire in a single spreader: reliability, speed, accuracy, versatility and easy use

• A sturdy structure is capable of sustaining the pace of intensive productions. Important ergonomics was built into the machine design to safeguard the operator’s well-being

• A special system for fabric roll loading facilitates feeding the machine. The Fox 2 80 PRO is suitable for preparation of flat spreads or regular and irregular step lays

• Fox 2 80 PRO optimum performance is especially showcased in productions with elastic or light fabrics

Technical Specs:

• Max. Spreading speed 100 m/min

• Effective spreading width 180, 230 cm

• Max. Roll weight 80 Kg

• Max. Roll diameter 60 cm

• Voltage / Frequency 400 V 3Ph+N 50/60 Hz

Bottom Hemming and Trousers Turning machines by EFATECH

Efatech puts the advantages of textile automation systems at project, education, maintenance and repair cares into sector’s disposal with the engineer knowledge and experience it has. Provides the sectoral requirements with projects based on research & development and by knowing sectoral points, requirements and necessities, expert staff, productive business planning through the experience. Efatech has maintained enthuesiasm and willingness from the very first day for its customers’ full satisfaction at textile automation systems with the attitude of safe service, professional technical support and customers’ pleasure, since 2014. Efatech provides the highest level in parameters like speed, accuracy, ease in use, flexibility, alterability, robustness in textile automation systems.

Efatech puts the advantages of textile automation systems at project, education, maintenance and repair cares into sector’s disposal with the engineer knowledge and experience it has. Provides the sectoral requirements with projects based on research & development and by knowing sectoral points, requirements and necessities, expert staff, productive business planning through the experience. Efatech has maintained enthuesiasm and willingness from the very first day for its customers’ full satisfaction at textile automation systems with the attitude of safe service, professional technical support and customers’ pleasure, since 2014. Efatech provides the highest level in parameters like speed, accuracy, ease in use, flexibility, alterability, robustness in textile automation systems.

PC-40V3H – Bottom Hemming Machine (Heavy Duty Fabric)

Technical Specifications:

• Options – PC-40V3H For Denim Fabrics (Lockstitch Type)

• Sewing Head – Designed By Efatech – Aluminium Sewing Head

• Production Capacity – 230-250 Pieces/Hour

• Max Sewing Speed – 3500 rpm

• Pneumatic Group – Smc

• Automation Group – Mitsubishi

• Stitches Per Cm – 1-10 Stitches (Can Be Set From Touch Panel)

• Hemming Parameters – 1 To 4 Cm Width 14 To 55 Cm Lenght

• Noise – Machine Noise When Machine Operated 3500 Rpm Lpa< 84db

• Bottom Puller – Adjustable Servo Motor

• Sewing Head Motor – Direct Drive Servo Motor

• Sewing Head Motor – Direct Drive Servo Motor

• Top Puller – Adjustable Servo Motor

• Voltage – 220 V

• Power – 1.5 Kw / 10 A

• Air Pressure – 6-7 Bar

• Net Weight – 125 Kg

• Gross Weight – 160 Kg

PC-500 – Trousers Turning Machine

Technical Specifications

• Voltage – 380 V

• Power – 3 Kw / 16 A

• Production Capacity – 350 Pieces/Hour

• Noise – Machine Noise When Machine Operated 3500 Rpm Lpa< 84db

• Air Pressure- 6-7 Bar

• Net Weight – 300 Kg

• Gross Weight – 450 Kg