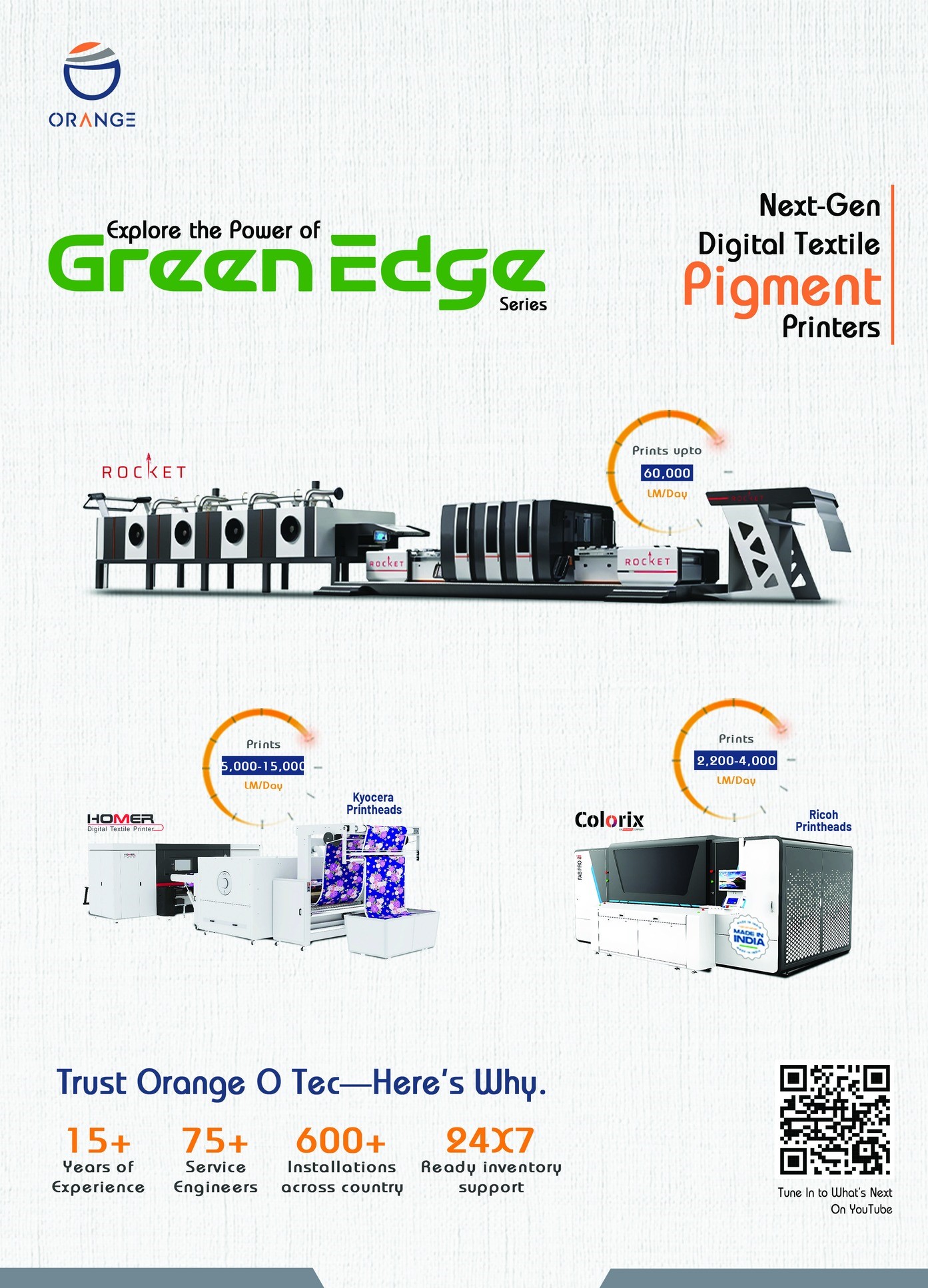

Software Solutions by Optitex

From design to production – we specialize in digital innovation. Our groundbreaking software solutions include 2D design and 3D visualization platforms that cover the entire supply chain, create efficient workflows, and shorten time to market. With over 25 years of fashion and apparel innovation history, we live and breathe this fast-paced market. We’ve acquired the ability to quickly respond to its changing demands and provide trusted consultation on how to future-proof your business, empower your creative vision and grow your bottom line. Fast fashion powered by Optitex – experience digital innovation in all its glory.

From design to production – we specialize in digital innovation. Our groundbreaking software solutions include 2D design and 3D visualization platforms that cover the entire supply chain, create efficient workflows, and shorten time to market. With over 25 years of fashion and apparel innovation history, we live and breathe this fast-paced market. We’ve acquired the ability to quickly respond to its changing demands and provide trusted consultation on how to future-proof your business, empower your creative vision and grow your bottom line. Fast fashion powered by Optitex – experience digital innovation in all its glory.

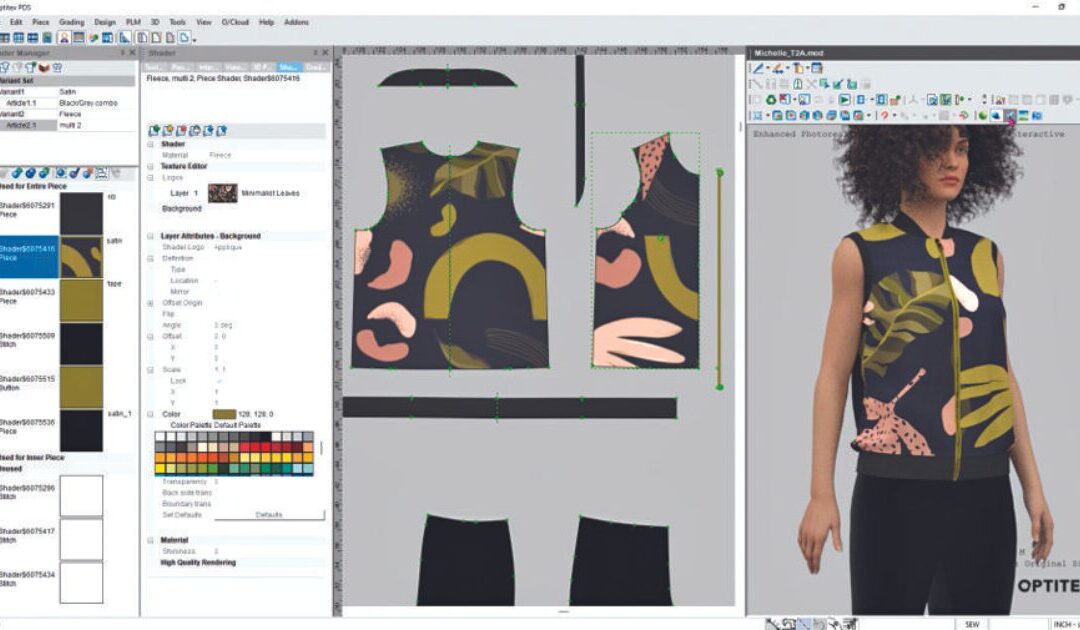

Pattern Design Software (PDS)

Developed exclusively for today’s pattern makers and technical designers, Optitex Pattern Design Software (PDS) delivers a wealth of tools, features, and functionality to seamlessly create, modify, grade, and validate digital patterns while eliminating hundreds of manual steps in the development process. With over three decades of market-proven experience and expertise, Optitex provides pattern makers in the apparel, upholstery and technical textile industries with a smart and efficient interoperable 2D/3D platform. Matched with an intuitive user interface, Optitex PDS accelerates development time, and streamlines patterns from the development stage, straight to production.

Key benefits:

• Immidient output of production-ready patterns

• The most open CAD for integration

• Great user experience and rich technical design toolset

• Interoperable 2D/3D platform for reliable design validation and virtual sampling

• Highly accurate simulation with flexible avatar platform

• Trusted pattern accuracy and fit predictability

Marker

Marker

Optitex Marker optimizes fabric usage through nesting. Compatible with most plotters and cutters, this tool streamlines your workflow, boosting productivity and sustainability through saving the amount of fabric used and cutting down on needless waste. Marker’s ease of use allows users to quickly create multiple marker files, play with constraints and create reports in order to quickly and easily view where savings could be made and costs reduced.

Key benefits:

• Define marker orders

• Place and manipulate pieces

• Optimize fabric usage

• Automated nesting

• Apply nesting constraints

• Customizable data reports

O/Cloud

Our O/Cloud platform seamlessly integrates into your workflow, providing a collaborative environment for your development and production teams. O/Cloud facilitates real-time collaboration, enabling team members to work on projects simultaneously, regardless of their physical location. This cloud-based platform ensures secure access to your working assets, fostering efficient communication and streamlined workflows.

Key benefits:

• Store and manage all your product files in a single digital workspace

• Easily share and collaborate all your product assets in a centralized location, with teammates, suppliers, and partners

• Get earlier feedback before preparing the first physical prototype

• View garments in side-by-side views, to compare sizes sets, fit and colorways

• Run online fit sessions on your 3D files and leave comments to document your meetings

• Set your presentation board with inspiration images, 3D colorways and size options, mix & match

scenarios, material swatches, and more

• Fully control permissions and be confident that only relevant supply chain members can access your data.

New Feed-off-the-arm Flatseamer is launched by Yamato Sewing Machine

Yamato Sewing Machine Mfg. Co., Ltd. have been launched “Made in Japan” new feed-off-the-arm flatseamer, FD-62SD-LF, designed for stretch materials that reduces defects and achieves extra stretch, outstanding appearance, comfort & functionality.

Yamato Sewing Machine Mfg. Co., Ltd. have been launched “Made in Japan” new feed-off-the-arm flatseamer, FD-62SD-LF, designed for stretch materials that reduces defects and achieves extra stretch, outstanding appearance, comfort & functionality.

Unique features of YAMATO FD-62SD-LF, New Feed-off-the-arm Flatseamer

Extra Stretch, Without the Risk for Breakage

With the new design that securely tightens the needle thread at low tension, the seam stretchability is improved by 30 percent. This significant reduction in needle thread half catch and seam jams ensures high-quality seams required in premium products.

Innovative New Technology for the Perfect Seam

FD-62SD-LF’s innovative technology makes it possible to create flat and wide enough seams without the risk of damaging fabric by retainer needle.

Contribute to Downtime Reduction

FD-62SD-LF helps customers improve profitability. FD-62SD-LF is equipped with advanced technologies that reduce quality and time waste. It meets advanced sewing needs without the need for complicated adjustments and reduces the risk of seam breaks, needle holes, and oil stains.

Yamato Sewing Machine are sure that said features of FD-62SD-LF would be of great help in production of highly functional and supreme quality garments, like our “Active thread control” technology, introduced to our Made in Japan interlock stitch machine that help you applicable for wide variety of sewing conditions, including ultra-stretch seam, which cannot be achieved conventional sewing machines.

Reduce waste and boost profits in spinning at ITM 2024

Spinners seeking profitable investments for sustainable mill operations would do well to check out Uster FiberQ and RSO 3D. Both these systems offer attractive ROI. They also help spinners control the most expensive stages in the mill process, cutting waste and boosting profits.

Spinners seeking profitable investments for sustainable mill operations would do well to check out Uster FiberQ and RSO 3D. Both these systems offer attractive ROI. They also help spinners control the most expensive stages in the mill process, cutting waste and boosting profits.

Field tests show that comprehensive raw material management can save 0.5% to 2% of waste. Every spinner wants maximum profitability from yarn production, so this evidence should be examined seriously. All the details will be available at ITM 2024, where Uster experts will welcome visitors to Booth 714B in Hall 7. Here we present some of the compelling attractions of these systems. For example, if barré faults and quality consistency are major headaches, spinners are recommended to read on.

Manage the big cost factor

Raw material accounts for 65% to 75% of the production costs for cotton yarn. Saving even a single percentage of waste here can be significant: a cost reduction of USD 255,000 (€ 239,000) per year, is typically achieved for a mill with 50,000 spindles, based on Ne 30 yarn with a price of 1.8 USD per kilogram of cotton. This savings potential can be tapped with Uster FiberQ – the complete solution for raw material utilization – supporting spinners’ daily processes, quality consistency, profitability and further growth.

Optimum sourcing and use of raw material needs to take account of inventory levels, required yarn quality, and cotton parameters. FiberQ software simplifies the process and integrated Uster Application Intelligence cuts through the complexity, unlocking maximum potential.

Uster FiberQ works with powerful software, analyzing fiber data from available inventories and creating consistent and reliable laydowns for optimum quality and performance. The basis is reliable raw material data, measured by Uster HVI1000. With FiberQ, the Uster fiber classification and analysis system is accessible through a subscription model.

Think Quality next level

FiberQ has three elements. It combines data-enabled software, cutting-edge hardware and textile expertise. So the global know-how and experience of Uster experts opens new perspectives for quality and profitability. Textile expertise brings all the capabilities of equipment, data and software tools into the mill context. Uster textile experts work with the mill’s own personnel to train them and help shorten the road from testing to real results.

The FiberQ quality promise is already proven in practice. Spinners report significant quality improvements. For example, no barré faults occurred after the FiberQ solution was installed. The overall IPI quality improvements showed a level of >25% and greater consistency was observed.

Potential in the most cost-intensive process

Many Uster customers are convinced that investing in quality equates to increasing profitability. Uster RSO 3D is another example of a secure investment in the mill’s future. It’s an intelligent combination of Uster Sentinel ring spinning optimization system, Uster Quantum 4.0 yarn clearers and a linked winding machine with spindle identification. It adds up to a unique preventive quality control for textile mills. These three dimensions of quality measurement in one system achieve the ultimate goals of process optimization and traceability.

Individual data for each spindle enables quality mapping throughout the ring spinning machine, and any poor quality production is indicated right there. Outlier cops are ejected through direct machine intervention, before winding. This significantly reduces winder stops and clearer cuts. The system also guides operators to the exact position where an issue is identified, enabling fast action for minimum losses – and maximum profitability.

Typically Uster

Spinners know they need to adopt innovative techniques and technologies to meet business challenges and ensure long-term sustainability and profits. Previously, quality management has been largely based on the experience of mill personnel, with available tools at the level of Excel files. This resulted in low utilization of data, because of the complicated and time-consuming processes – which even then could not offer best results.

Data-enabled software is the key to progress and success. Uster offers reliable measuring systems and powerful software, analyzing data from different sources for optimum yarn quality and performance, every day.

TOLKAR focuses on environmental and corporate sustainability with its solutions

TOLKAR, standing out with its textile finishing and laundry technologies, is taking its place at ITM 2024 to meet the local and global market during the busy business season. The company will host its visitors at Hall 11A Booth 1130/B at the international textile technologies exhibition ITM 2024 to be held in TÜYAP on June 4-8. TOLKAR will attend the exhibition with an information booth this year, while sharing its new product and system launches with ITM visitors via video. Making a difference in recent years with textile solutions based on environmentally friendly and sustainable ozone technology, the company will introduce the TOLKAR FUTURE Central Control System and TOLKAR FUTURE Automatic Loading and Unloading through Automation system this year.

TOLKAR, standing out with its textile finishing and laundry technologies, is taking its place at ITM 2024 to meet the local and global market during the busy business season. The company will host its visitors at Hall 11A Booth 1130/B at the international textile technologies exhibition ITM 2024 to be held in TÜYAP on June 4-8. TOLKAR will attend the exhibition with an information booth this year, while sharing its new product and system launches with ITM visitors via video. Making a difference in recent years with textile solutions based on environmentally friendly and sustainable ozone technology, the company will introduce the TOLKAR FUTURE Central Control System and TOLKAR FUTURE Automatic Loading and Unloading through Automation system this year.

TOLKAR has created a strong vision for sustainable textile production with washing solutions based on ozone technology in recent years, and its focus at ITM is on increasing production costs and corporate sustainability. Thanks to the TOLKAR FUTURE Central Control System and Automatic Loading and Unloading through Automation system that will be launched, textile manufacturers and laundry administrators will be able to achieve greater efficiency. These innovations, developed as a response to cost increases and sustainable savings demands, once again show that the company is a leader with solutions that make a difference ecologically and economically.

Digital control and increased automation increase corporate sustainability

Developed by the TOLKAR R&D unit consisting of competent engineers and interdisciplinary experts, the TOLKAR Future Automation Controlled Smart Conveyor System optimises the recipe process based on manual calculations. This system, connected to the central system through the operator, feeds the machine by calculating the correct amounts of water, chemicals and all other materials required for production. In this way, textiles and laundry are processed and washed in accordance with the desired programs and recipes. This makes it possible to calculate production costs accurately while maintaining standard product quality.

Developed by the TOLKAR R&D unit consisting of competent engineers and interdisciplinary experts, the TOLKAR Future Automation Controlled Smart Conveyor System optimises the recipe process based on manual calculations. This system, connected to the central system through the operator, feeds the machine by calculating the correct amounts of water, chemicals and all other materials required for production. In this way, textiles and laundry are processed and washed in accordance with the desired programs and recipes. This makes it possible to calculate production costs accurately while maintaining standard product quality.

TOLKAR conveyor system, which performs automatic loading and unloading through a central control system and automation, was designed as a necessary solution for new generation laundries. With machines and carrier conveyors communicating with each other, this system increases the efficiency, daily production speed and volume in the facility. Among the main advantages of the system, the following stand out: 90% labour savings with the help of automatic loading conveyor and shuttle; Minimization of efficiency and time losses due to operator errors; Maximum efficiency through fast loading and unloading; Minimum chemical usage through automatic chemical dosing; Recipe transfer and machine selection from the central system control unit; Drying outlet conveyor and reporting.

TOLKAR’s rich product range also includes part dyeing machines and stone washing machines. While part dyeing machines provide high efficiency and flexibility, especially in large capacity production and special colour demands, stone washing machines make it possible to achieve the desired texture and appearance of denim and other heavy fabrics. These machines are designed to support sustainable production by being equipped with environmentally friendly processes and energy-saving technologies. These advanced solutions offered by TOLKAR enable both production in accordance with high-quality standards and minimization of costs and environmental impact. Smartex Miracle industrial washing machine, produced by TOLKAR, has the advantages of 50% less water, chemicals, steam and wastewater and 40% less electrical energy consumption compared to its competitors with the same kg capacity. Moreover, Smartex Miracle achieves this without vibration with a clamping force of 400G.

TOLKAR’s rich product range also includes part dyeing machines and stone washing machines. While part dyeing machines provide high efficiency and flexibility, especially in large capacity production and special colour demands, stone washing machines make it possible to achieve the desired texture and appearance of denim and other heavy fabrics. These machines are designed to support sustainable production by being equipped with environmentally friendly processes and energy-saving technologies. These advanced solutions offered by TOLKAR enable both production in accordance with high-quality standards and minimization of costs and environmental impact. Smartex Miracle industrial washing machine, produced by TOLKAR, has the advantages of 50% less water, chemicals, steam and wastewater and 40% less electrical energy consumption compared to its competitors with the same kg capacity. Moreover, Smartex Miracle achieves this without vibration with a clamping force of 400G.

Ata Karace; We are taking special steps towards revived markets

TOLKAR Board Member Ata Karace stated that ITM has always been an important exhibition for the textile markets in Türkiye and the region, and said that they were happy to participate in this edition with innovations. Explaining that they expect to meet visitors, especially from the Middle Eastern and Southeast Asian countries at the exhibition, as well as the Turkish textile industry, he continued his words saying; “As a company that exports to more than 90 countries, we act with a global market plan. We know that each region’s textile production priorities and market conditions are different, and we take special steps for each region accordingly. We expect ITM 2024 to be more active, with the impact of the revival that started in several markets after the pandemic. During the exhibition, we will explain our new control and automation systems as well as our most suitable finishing and laundry solutions to textile professionals. In today’s difficult market conditions, efficiency has now become the first and priority step of profitability. We are really excited to tell our visitors about the unrivalled contribution that TOLKAR solutions provide to their businesses.”

TOLKAR Board Member Ata Karace stated that ITM has always been an important exhibition for the textile markets in Türkiye and the region, and said that they were happy to participate in this edition with innovations. Explaining that they expect to meet visitors, especially from the Middle Eastern and Southeast Asian countries at the exhibition, as well as the Turkish textile industry, he continued his words saying; “As a company that exports to more than 90 countries, we act with a global market plan. We know that each region’s textile production priorities and market conditions are different, and we take special steps for each region accordingly. We expect ITM 2024 to be more active, with the impact of the revival that started in several markets after the pandemic. During the exhibition, we will explain our new control and automation systems as well as our most suitable finishing and laundry solutions to textile professionals. In today’s difficult market conditions, efficiency has now become the first and priority step of profitability. We are really excited to tell our visitors about the unrivalled contribution that TOLKAR solutions provide to their businesses.”

Single-Ply Cutter and Spreading Machine’s by KURIS

KURIS currently offers one of the most comprehensive product programs in the field of spreading and cutting technology. KURIS has its headquarters at Reichenbach in Baden-Württemberg, the home of German mechanical engineering. This location in a high-technology area guarantees solutions with a high degree of automation. At the same time, KURIS possesses a notable store of experience with more than 10,000 installations worldwide. Development, design and construction are state of the Art. As a result, solutions come from a single source and are characterized by a high quality of engineering and modern control technology. We are likewise involved in the development of the relevant software. The wide-ranging product program enables individual answers that take full and systematic account of the organizational preconditions and local situation of the customer.

KURIS currently offers one of the most comprehensive product programs in the field of spreading and cutting technology. KURIS has its headquarters at Reichenbach in Baden-Württemberg, the home of German mechanical engineering. This location in a high-technology area guarantees solutions with a high degree of automation. At the same time, KURIS possesses a notable store of experience with more than 10,000 installations worldwide. Development, design and construction are state of the Art. As a result, solutions come from a single source and are characterized by a high quality of engineering and modern control technology. We are likewise involved in the development of the relevant software. The wide-ranging product program enables individual answers that take full and systematic account of the organizational preconditions and local situation of the customer.

Single-Ply-Cutter

fiber, carbon fiber, Honeycomb material (Honeycomb) and special materials. As for the variety of parts, there are fast and flexible options. All targeted is a maximum productivity and optimum production quality. The tool technology can individually and precisely be adapted to the respective material and achieves always optimal

cutting conditions. The fourth generation is equipped with the Multi-Flex Tool adaptation.

As a fast and compact single-ply cutter this system persuades with fast positioning and cutting speed besides of extremely short plunge time. The tool-change system reduces the set-up time considerably because less adjustment operations are necessary. The consistent user interface and menu navigation is responsible for an easy handling. Operation errors and training costs are drastically reduced according to a mobile and innovative control system.

Spreading-Machine

Spreading-Machine

The Kuris Shuttle spreading machine suits perfectly for critical, smooth materials and/or even badly rolled material bars with different surfaces. The new deviating roller system of the driven cradle or material bar ensures an excellent quality in spreading. Even through fully automatic spreading of tension-sensitive materials excellent spreading results will be achieved. The precise and regulated prefeed material roll will exactly suit the required spreading speed.

The semi of fully automatic unthreading/threading of the fabric will reduce essentially the set-up times. Many steps to be taken for the spreading with different positioning and cutting points, quantity of layers, zig-zag spreading programmers as well as numerous custom-made parameters can be individually programmed.

Advantages at a glance:

• Cradle with fully automated lifting for ergonomic loading process

• A new idler-pulley system for the continuous running of the conceyor belt (option)

• User-friendly machine control

• Graphical user interface

• Easy to use

• Software update possible even after several years of use

• Programming possibilities for many spreading steps

• Silicon coated drive wheel

• Photocell electric for the examination of the edge control even for difficult materials

• Different cutting units simply to be mounted

• Dynamic speed control

• Robust control cabinet-housing with power coating surface

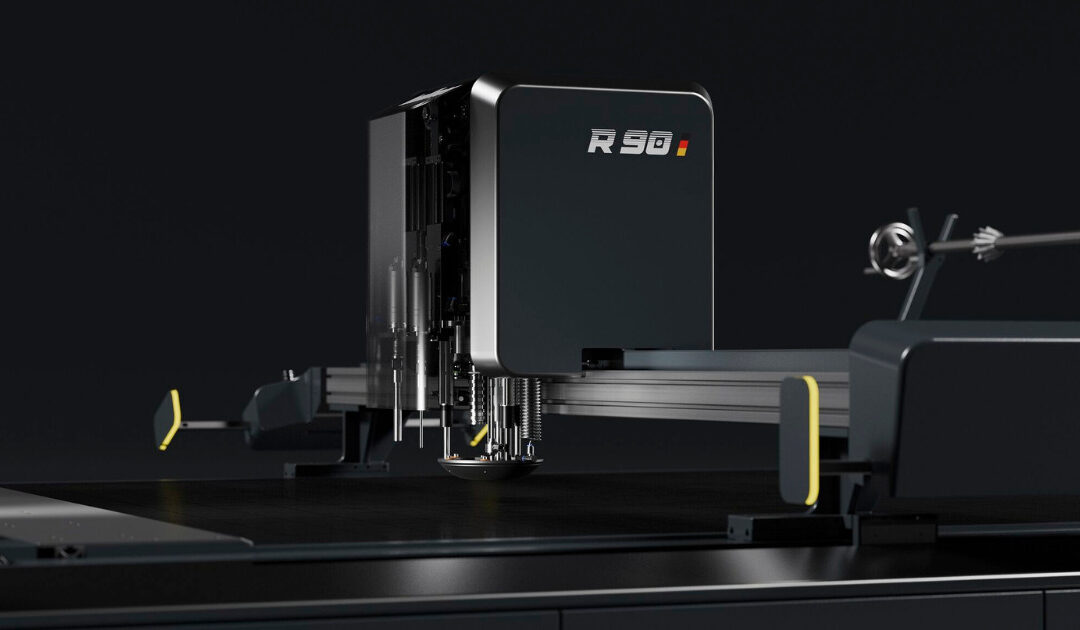

Discover the future of cutting technology by bullmer

Discover the future of cutting technology with our groundbreaking innovations. Every step we take is designed to make a difference and exceed your expectations.

Discover the future of cutting technology with our groundbreaking innovations. Every step we take is designed to make a difference and exceed your expectations.

Our completely new grinding unit sets new standards in terms of efficiency and precision. Continuous cutting with feed makes every cut a seamless experience. And with our segmented precision cuts, you can count on seamless cutting for perfect results on every project.

But that’s just the beginning. Our optimized vacuum pump technology ensures an even more effective way of working, while our exclusive design innovation in partnership with renowned designers ensures that our machines are not only technically brilliant, but also visually impressive.

And to enable you to work even faster and more flexibly, we offer you a quick-change system for the drilling units as well as a new high-precision knife guide. With our gantry drive for the X-axis, you can achieve unmatched precision and speed.

But our innovations are not limited to hardware. Our Bullmer machine software is a revolutionary solution that gives you full control over your production. And with the shortened infeed plate of the transfer bridge for clearing on Transclear, you will experience a smooth workflow like never before.

It’s time to push the boundaries of what’s possible and set new standards with our innovative solutions. Step into a world of uniqueness and creativity. Let’s make the difference together.