Latest Sewing Machines by Juki

Juki is a Japanese company renowned for its innovative technologies and superior quality, a world leading brand in the manufacture of sewing machines for the industrial and home sewing machine markets. Juki Corporation has been a pioneer in sewing machine technology for over 80 years. The firm supplies more than 170 nations with sewing equipment and related products and with established logistic networks we have the ability to supply the world with the best quality products. The Juki Corporation headquarters are located in Tokyo, Japan, with subsidiaries worldwide assisting in its sales, logistics and technical functions. The firm’s insight into the world of sewing machine manufacturing began with home machines in 1947 from which we progressed to basic industrial machines becoming the world leader we are today.

Juki is a Japanese company renowned for its innovative technologies and superior quality, a world leading brand in the manufacture of sewing machines for the industrial and home sewing machine markets. Juki Corporation has been a pioneer in sewing machine technology for over 80 years. The firm supplies more than 170 nations with sewing equipment and related products and with established logistic networks we have the ability to supply the world with the best quality products. The Juki Corporation headquarters are located in Tokyo, Japan, with subsidiaries worldwide assisting in its sales, logistics and technical functions. The firm’s insight into the world of sewing machine manufacturing began with home machines in 1947 from which we progressed to basic industrial machines becoming the world leader we are today.

DDL-9000C Series (Direct-drive, High-speed, Sewing System with Automatic Thread Trimmer)

DDL-9000C Series (Direct-drive, High-speed, Sewing System with Automatic Thread Trimmer)

JUKI’s new direct-drive, high-speed, lockstitch sewing system with automatic thread trimmer – the DDL- 9000C. This is the newest flagship lockstitch machine from the world’s largest industrial sewing machine manufacturer. The machine has been digitalized to allow for easy adjustment of settings such as the feed mechanism, thread tension and the feed locus, all through the operation panel. Perfect parameters needed to achieve a high quality seams can beachieved digitally and key conditions do not need to be manually adjusted. Thanks to the digitalization, optimum adjustment values required to produce high-quality seams can be stored on a material-by-material basis in the machines internal memory and can be reproduced with ease. For factories which produce

diversified products using different materials, this feature is quite helpful to achieve stable seam quality in a time efficient manner.

AMS-251 (Head Turning type1 Needle CNC Sewing Machine)

AMS-251 is a high end 1 needle sewing machine provided with a machine-head-turning-mechanism. The new model guarantees high quality seams uniformly in every sewing direction. JUKI’s unique synchronization technology guarantees stable control of the machine head, hook an feed mechanism, thereby creating the most favorable seams. With it’s sewing area of “1.000 mm × 600 mm” the AMS-251 is best suited to the sewing of decorative stiches and large size products. The AMS-251 is ideally suited to the sewing of decorative stiches on car seats and luxury bags as well as air bags and other large size products with zero design tolerance for irregular stitching.

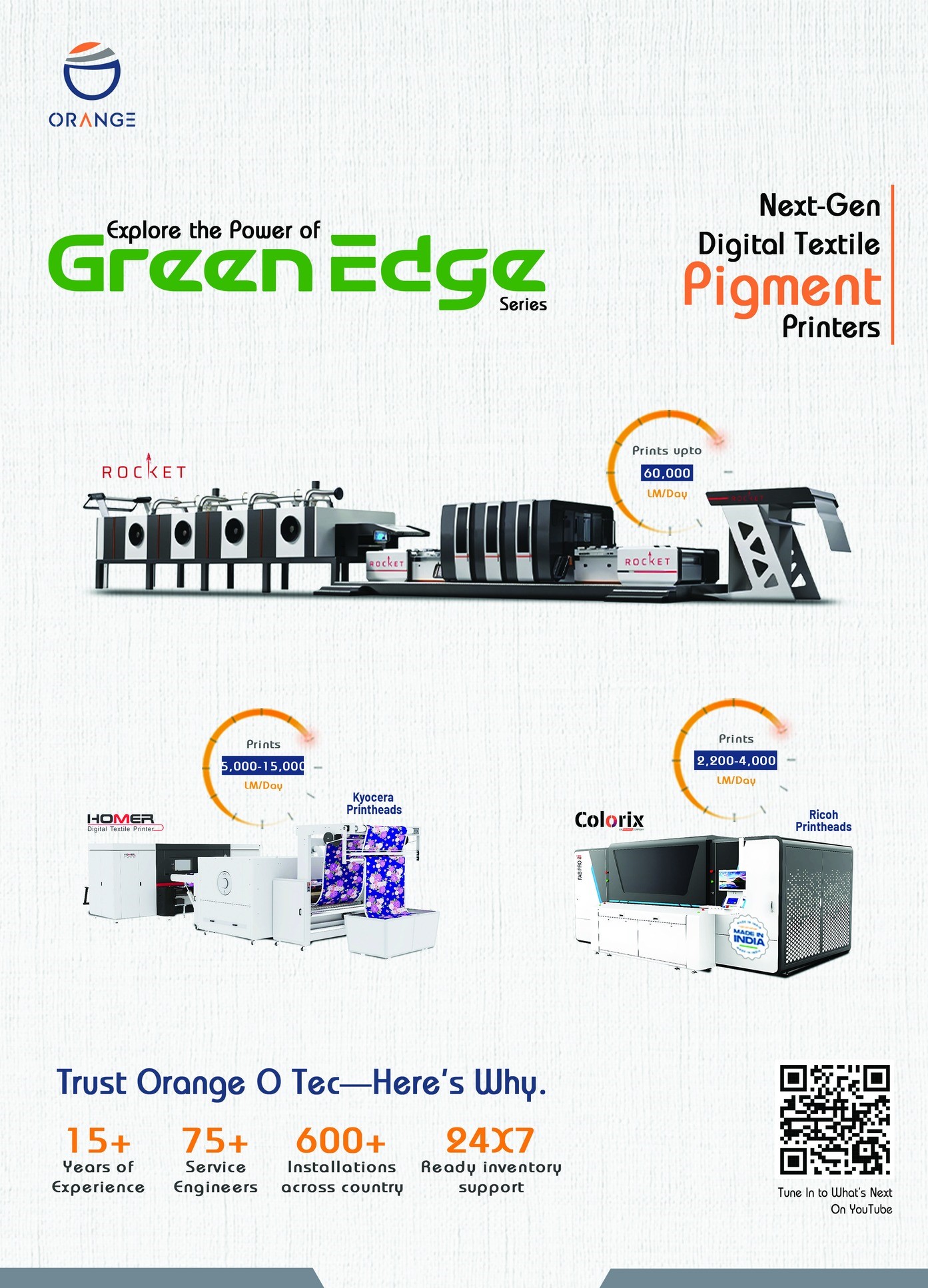

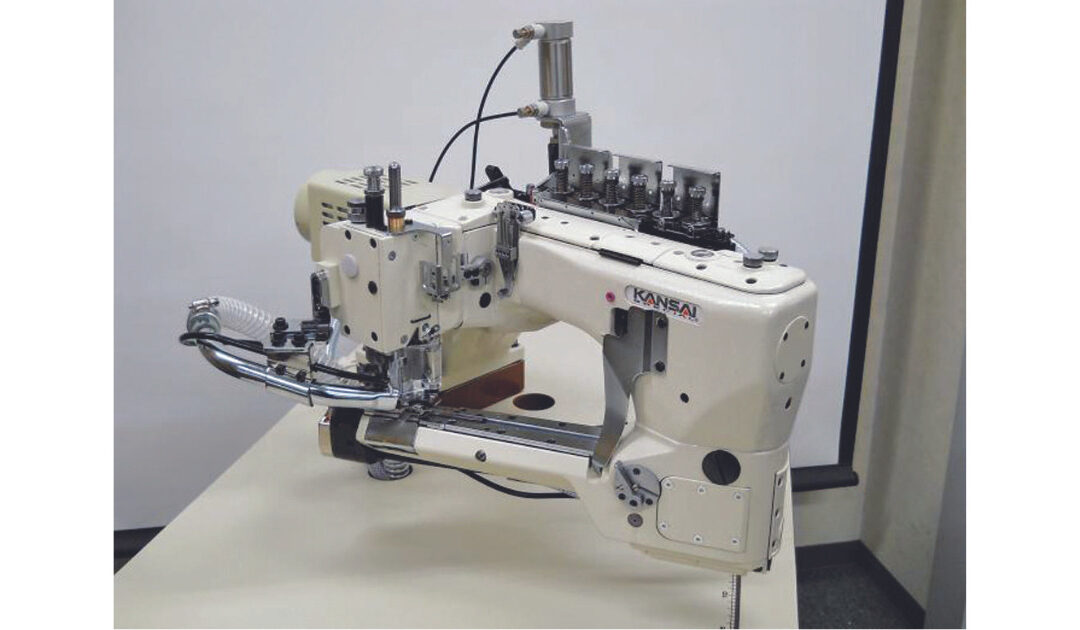

Feed-off-the-Arm and Flatseamer by Kansai Special

More than 60 years specialists in chain stitch and cover stitch machines made in Japan Kansai Special operate worldwide through its own subsidiaries and a diversified dealer network. Its product range covers machines for following sectors: Jeans & work wear, sportswear, underwear, knitwear, children’s and ladies’ wear – from 1 up to 33 needle machines.

More than 60 years specialists in chain stitch and cover stitch machines made in Japan Kansai Special operate worldwide through its own subsidiaries and a diversified dealer network. Its product range covers machines for following sectors: Jeans & work wear, sportswear, underwear, knitwear, children’s and ladies’ wear – from 1 up to 33 needle machines.

SQ7702FB/PF/AF/DD (Feed-off-the-Arm Machine for Lap Seaming of Shirts – with differential feed mechanism)

SQ series is square bed, 2~3needle double chain stitch machines for the following operations.

• Suitable for the crotch sewing and side seam such as jeans and working pants. and also for lap seaming of various kinds of fabrics

• Attaching the tape from the back neck to the shoulder

• And also, suitable for a lap seaming of shirts sleeves (light to medium thickness). And there are two kinds of differential feed dog which is right to left or front to back differential feed dog. These feed dogs are effective for preventing from sewing gap and puckering. Puller system is adjustable by the adjusting dial easily. And there are 2 kinds of puller systems either belt puller or smooth rubber roller

NFS6604GMH-DD (Flatseamer with Direct Drive and Pneumatic Chain Cutter)

4 needles, 6 threads feed-off-the-arm, flatseamer for medium to thick fabric equipped with both side cut presser foot, direct drive servo motor, digital hand pulley, pneumatic suction device & foot lifter.

Features

• Stitch length & differential ratio can be adjusted by levers from outside of the machine

• Adapted fixed type needle guard. Stitch length & differential ratio can be changed without adjusting the needle guard position

• Enclosed needle drive mechanism

• Direct drive servo motor, pres ser foot lifter & digital

• hand pulley are includede

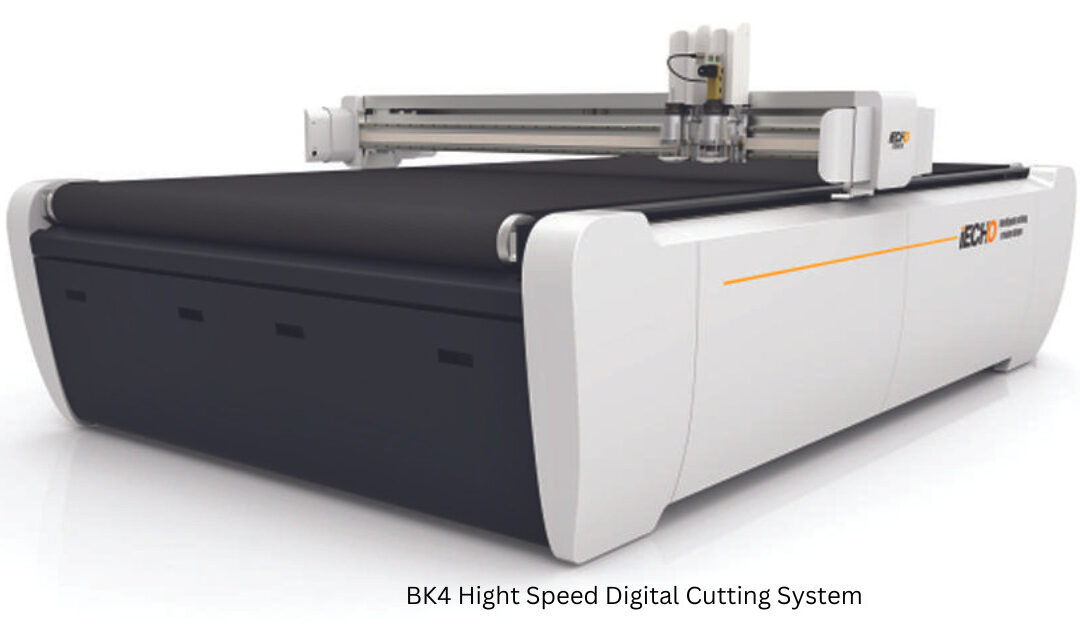

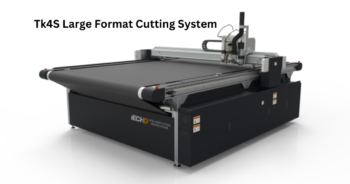

Hangzhou IECHO Science & Technology’s Cutting Systems

Hangzhou IECHO Science & Technology Co., Ltd. (Company abbreviation: IECHO, Stock code: 688092) is a global intelligent cutting solution supplier for non-metal industry. At present, the company has more than 400 employees, of which R&D personnel account for more than 30%. The manufacturing base exceeds 60,000 square meters. Based on technological innovation, IECHO provides professional products and technical services to more than 10 industries including composite materials, printing and packaging, textile and garment, automotive interior, advertising and printing, office automation and luggage.

Hangzhou IECHO Science & Technology Co., Ltd. (Company abbreviation: IECHO, Stock code: 688092) is a global intelligent cutting solution supplier for non-metal industry. At present, the company has more than 400 employees, of which R&D personnel account for more than 30%. The manufacturing base exceeds 60,000 square meters. Based on technological innovation, IECHO provides professional products and technical services to more than 10 industries including composite materials, printing and packaging, textile and garment, automotive interior, advertising and printing, office automation and luggage.

TK4S Large Format Cutting System

TK4S Large Format Cutting System provides best choice for multi-industries automatic processing, Its system can be precisely used for full cutting, half cutting, engraving, creasing, grooving and marking. Meanwhile, precise cutting performance could meet your large format requirement. User-friendly operating system will show you a prefect processing result.

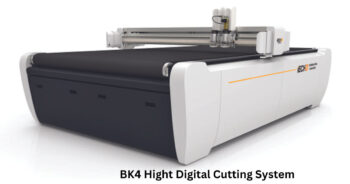

BK4 High Speed Digital Cutting System

BK4 High Speed Digital Cutting System

Iecho new BK4 Cutting System is for single layer (few layers) cutting can work on process automatically and accurately, like through cut, milling, V grove, marking, etc. It can be widely used in the industries of automotive interior, advertising, furniture and composite, etc. Bk4 cutting system, with its high precision and efficiency, provides automated cutting solutions to variety of industries.

Pattern Making Suite and Artificial Intelligence by Crea Solution

2D/3D Pattern Making Suite

Crea Solution stands at the forefront of innovation in the software and hardware systems, specializing in the comprehensive journey from design and pattern making through to fabric cutting. The company is player in the fashion, luxury, high-end leather goods, made to measure, home furnishings, and even the maritime and composite materials industries. Crea Solution is particularly renowned for its innovative range of products: CAD 2D/3D and nesting Suite, Artificial Intelligence and Vision system for cutting fabrics and Made to Measure integrated platform. Crea Solution MTM/MTO platform revolutionizes the production process by reducing the time from order receipt to fabric cutting to a mere 120 seconds, automating the entire workflow with unparalleled efficiency.

2D/3D Pattern Making Suite

Create™ is the Crea Solution 2D CAD Suite to create and modify patterns for fashion industry, fully integrate with 3D CAD Browzwear.

• Garade sized automatically

• Design a whole pattern base in only 10 seconds thanks to the macro functions integrated in the CAD

• Import and work on pattern created by other CADs

• Accelerate your creative flow

• Digitize your patterns in 4 different ways

• Become a Crea CAD expert in ONLY 3 DAYS of training, thanks to the reduction of designing times, designers are able to fully express their creativity

MTM MTO Artificial Intelligence

Crea Solution has the only 100% fully automated process exploiting AI (Artificial Itelligence) to get the highest top-level quality of a Made to Measure/ Made to Order cloth with no manual work or pattern making skills.

Lets see all the automated steps that require no manual work and no specific skills (pattern making):

• Measurement taken in the shop (manually or via body scanner)

• Measures insertion in a web platform from the shop assistant and automatic creation of the order

• Automatic creation of MTM / MTO pattern

• Automatic nesting

• Artificial Vision of the fabric on the digital cutter and re-adaptation of the marker according to the conditions of the fabric (squares, stripes, repeated motifs, defects, folds …)

• Automatic cut

• The cut patterns are ready to be sewed

Automatic Belt Loop and Pocket Setter by Jam International

Jam International is an Italian industry which develops and produces in Italy special high-tech machines and devices for clothing industry, particularly for jeans & casual. Jam International products are the best offered in the world market concerning quality, productivity and functionality. These products are developed with the highest professionalism in manufacturing machinery and devices, combined with a deep knowledge of customer’s production requirements. Jam International has a Research, Development and Design department with highly qualified staff working under the direction of thirty-years experienced specialists. The applied technology is innovative and for the most part patented.

Jam International is an Italian industry which develops and produces in Italy special high-tech machines and devices for clothing industry, particularly for jeans & casual. Jam International products are the best offered in the world market concerning quality, productivity and functionality. These products are developed with the highest professionalism in manufacturing machinery and devices, combined with a deep knowledge of customer’s production requirements. Jam International has a Research, Development and Design department with highly qualified staff working under the direction of thirty-years experienced specialists. The applied technology is innovative and for the most part patented.

JT801M – Automatic Belt Loop Setter

The machine is equipped with:

• JAM International double needle bar sewing head with servo direct motor, double capacity hook and thread trimmer

• X-Y axes movement driven by stepper motors

• Loop catcher clamp and loader device driven by brushless motors

• Electronic self-learning system managed through the touch screen for detecting the junction or the lack of the loop

The intuitive color touch screen panel allows, moreover, to:

The intuitive color touch screen panel allows, moreover, to:

• Choose from 3 preset standard bartack shapes (“X”, “O” and “double” shape);

• Program new bartacks starting from the standard ones and customizing the size and number of stitches;

• Set the start of the bartack (left, center, right);

• Choose the number of straight lines under the bartack (1, 2 or 3) and the corresponding stitch length;

• Make (on request) customized bartacks, different from the standard ones.

JT862M – Automatic Pocket Setter with Sewing Head in electric axis and folding group

The automatic unit JT862M is a programmable area pocket setter on jeans and similar, with a new folding unit 270×270 mm and an automatic stacker.

• Sewing head: Equipped with a JAM International lockstitch sewing head with direct motors, large capacity rotary hook and thread trimmer which, thanks to the electric axis, allow to process the pieces wider than average.

• Programmable electronic thread tension: Thread tension electronically controlled and settable through the touch screen. It is possible to program different tensions within the pocket sewing cycle

• Thread extension/thread lock: The thread extension / thread lock device allows to set through the touch screen the length of the residual thread after the thread trimmer and to obtain maximum quality at the next seam beginning.

• 5-movements folding group: It gives the possibility to sew non-standard pockets, such as the square pocket or with rounded corners, with excellent quality. The cold folding system guarantees high quality production standards even on the most difficult fabrics such as stretch, super stretch and knitwear.

• Pocket JIG: The pneumatic release allows changing the pocket jig in a few seconds. Thanks to a patented system, the customer has the possibility to create the templates independently in a simple way and by the use of common tools.

Single Layer Cutter PREMIUMCUT by bullmer

bullmer is a specialist in and supplier of innovative cutting technology and is one of the leading companies in its industry. bullmer machines stand for trendsetting manufacturing solutions that achieve the highest levels of efficiency and productivity. Bullmer has researched, developed and installed automated machinery for material handling and material flow as well as automatic cutting solutions for the textile and flat material processing industry worldwide for more than 80 years. At its Southern German site and competence centre, bullmer constantly develops and distributes economic machine concepts. In addition to customised applications, our focus is on connecting modules to achieve reasonable process chains.

bullmer is a specialist in and supplier of innovative cutting technology and is one of the leading companies in its industry. bullmer machines stand for trendsetting manufacturing solutions that achieve the highest levels of efficiency and productivity. Bullmer has researched, developed and installed automated machinery for material handling and material flow as well as automatic cutting solutions for the textile and flat material processing industry worldwide for more than 80 years. At its Southern German site and competence centre, bullmer constantly develops and distributes economic machine concepts. In addition to customised applications, our focus is on connecting modules to achieve reasonable process chains.

Single Layer Cutter PREMIUMCUT

Target group: Upholstered furniture industry, clothing industry, automotive industry, leather processing industry, processors of technical textiles and composites, graphic industry (packaging and printing)

Target group: Upholstered furniture industry, clothing industry, automotive industry, leather processing industry, processors of technical textiles and composites, graphic industry (packaging and printing)

Material use: Composites and technical textiles (woven and non-woven), rubber fabrics, floor coverings, home textiles, leather, fleeces and related materials, printed textiles, PVC, and much more.

Special features: The PREMIUMCUT is the most versatile single layer cutter.

It particularly shines with the following properties:

• Modular construction – can be retrofitted quickly and easily

• Easy to use thanks to quick and easy tool changes

• Customer-specific adjustments possible all materials – a cutter

• Working widths from 1400 mm to 5200 mm!

• Acceleration up to 2g and cutting speed up to 120m/min (2m/s)

• More robust drive system via 2 motors (gantrydrive)

• Material passage 60 mm (cutting height up to 50mm)

• Cut a wide range of thick materials on one machine!

• Low energy consumption vacuum pump

• The conveyor enables automatic material transport directly from the roll

Compact E100

• Target market: Clothing and upholstery industry as well as companies processing technical textiles.

• Materials: Technical textiles as well as normal and sensitive textiles.

• Outstanding advantages: Synchronized fabric unrolling with carriage speed for a strainless lay. Wind abrasive device for high speed spreading.