Latest apparel manufacturing technologies review

At Texprocess, the textile and apparel industries displayed their most progressive side and even in challenging times still inspired a positive mood throughout the sector as a result. Record numbers of exhibitors and the highest levels of international participation to date have once again confirmed Frankfurt as the sector’s global marketplace. With a total of 1,818 exhibitors from 59 countries and, in all, some 47,000 trade visitors from 116 countries, the two biggest editions of Techtextil and Texprocess ever to be held, ended in Frankfurt recently. Accordingly, for four days, the Frankfurt Fair and Exhibition Centre once again became the leading international platform for users of technical textiles from the widest variety of sectors, as well as for manufacturers of apparel, fashionwear, upholstered furniture and leather products. Texprocess was also all about digital solutions for the sector – from fully networked production lines in the form of micro-factories and machines capable of autonomous learning to cloud-based collaboration between designers, product developers, manufactures and retailers across national boundaries.

In the next few pages we are covering the second part of the review of latest apparel manufacturing technologies being presented during Texprocess show.

Caddon presents solution for printing and colour management

Caddon presents solution for printing and colour management

Caddon Printing & Imaging GmbH is a specialized manufacturer and service provider for digital, large-format printing and color management. From the system-controlled monitoring of the printer fleet to the calibration of monitors and printers through to innovative multispectral color measurement, caddon offers clients custom-made software and hardware solutions plus independent advice on the newest color and print management technologies.

can:view

An essential module of digital color communication is the standard light observer station can:view from caddon. It is almost impossible to judge colors even on conventional screen. Even if the monitor is perfectly calibrated, light and colours in the environment affect the viewer’s perception. At the can:view it does not matter, because the environmental influences can be faded out with one touch as far as possible. Remaining ambient light is measured and compensated.

• can:view is the only system in the world that allows an individual calibration of the observer. This can be used to calculate the viewer’s very personal colour perception during image display.

• can:view is the only system in the world that processes classic pre-press data and multispectral data. The patented process of can:view operation allows you to place physical patterns directly on the monitor and visually compare them with the screen image.

• This makes can:view the best prerequisite for binding control and proof-taking processes in the graphics industry and production.

• Using the software solution can:connect, different types of light can be calculated and displayed in the system.

• The viewer sees at a glance how a colour or design will look in the design office, in the production hall or in the neon light of the department store.

can:scan

can:scan is the core of the caddon color measurement technology. From Physical patterns true color digital patterns are produced. can:scan works like a spectral measurement per pixel of an image. In contrast to conventional spectrophotometers, can:scan makes it possible to precisely color detect complex colored patterned surfaces such as wood, leather or textiles.

Benefits

• Easy and fast production of color accurate multispectral samples.

• Highest precision in color measurement of patterned and structured surfaces such as textiles, plastics, leathers and woods. Aging problems with reference patterns are solved by multispectral patterns.

• Time and cost savings with the highest quality. Simple, lossless duplication and archiving, fast electronic data transmission.

• Multispectral patterns can be distributed worldwide via the Internet and measured on each computer at the click of a mouse. With can:view, the patterns can also be visually displayed and assessed in terms of color.

can:fabric

First spectral Knit & Weave samples for the valid colour prediction of a textile product. The new data format allows to create images from knitand weave-textures by using the 3DFabric system from company EAT in Krefeld and to colourize these with spectral values by using caddon can:connect. The source of the colours are either individually measured or already hosted spectral yarn colours. The coloured weaves and knits then serve as digital, colour-accurate samples for the communication between supplier and buyer. This allows a true-to-colour, realistic prediction of a product before it’s even physically created on a machine.

With spectral yarn values hosted in the colour database can:web, the fast evaluation of various bindings in combination of various yarn colours is realistic and fast. The textures generated in this way are just as suitable for digital pattern communication as they are for use in CGI / 3D visualization.

Groz-Beckert demonstrates its innovative strength

Groz-Beckert – the world’s leading supplier of industrial machine needles exhibited its comprehensive product and service portfolio in the knitting, weaving, felting, carding and sewing product areas. In the area of Knitting, Groz- Beckert exhibited its portfolio for the product areas of circular knit, legwear, knitwear and flat knitwear. The focus is on system solutions – precisely coordinated system components enable smooth interaction and thus ensure uniform appearance of the goods and increased process reliability. Another key topic is the expansion of the product portfolio, for example by offering needles in new intricacies – including coated needles. Additional needle types in the patented litespeed® plus version and new system components, which have been developed in close cooperation with machine manufacturers meet their high quality standards and complete the product portfolio. In addition, Groz-Beckert enables its customers to enter new business fields with individual developments for specific applications.

Groz-Beckert – the world’s leading supplier of industrial machine needles exhibited its comprehensive product and service portfolio in the knitting, weaving, felting, carding and sewing product areas. In the area of Knitting, Groz- Beckert exhibited its portfolio for the product areas of circular knit, legwear, knitwear and flat knitwear. The focus is on system solutions – precisely coordinated system components enable smooth interaction and thus ensure uniform appearance of the goods and increased process reliability. Another key topic is the expansion of the product portfolio, for example by offering needles in new intricacies – including coated needles. Additional needle types in the patented litespeed® plus version and new system components, which have been developed in close cooperation with machine manufacturers meet their high quality standards and complete the product portfolio. In addition, Groz-Beckert enables its customers to enter new business fields with individual developments for specific applications.

At Techtextil, Groz-Beckert’s Weaving product area presented its range of products for weaving preparation and weaving accessories. In addition, the trade fair stand will be offering both special healds and new insights into monofilament: In addition to highest row densities, these also allow a particularly thread-gentle processing. Combined with the innovative thread eye, which is not soldered but glued into the monofilament, Groz-Beckert healds ensure consistent fabric quality and maximum machine efficiency. The new ANTABRA surface treatment provides additional wear resistance.

The Felting area presented an absolute novelty with Groz-Beckert customized product: Thanks to the customizable customer label, Groz-Beckert customers not only benefit from enhanced know-how protection, but also from more security and safety when handling needles in production. Another highlight of the stand is the 3D print model of the staple fiber needling line (SVL). The SVL has been available to Groz-Beckert customers and partners for the last two years at the company’s Albstadt headquarters, in the Technology and Development Center (TEZ), in Germany.

Within the traditional nonwovens industry, Groz-Beckert’s GEBECON® felting needle offers the best possible fracture/bending properties and thus optimized needling parameters, as well as an improved surface quality of the final product. Groz- Beckert presented details of the patented shape of working part of this needle at the trade fair stand using a man-sized needle exhibit. Groz-Beckert also has such an exhibit ready for Spunlace customers: In addition to its improved handling properties, the innovative HyTec® P jet strip also has a significantly higher hardness, which has a positive effect on all mechanical properties such as scratch resistance, flexural rigidity and service life.

In addition, the Sewing area was on-site with INH (Ideal Needle Handling) quality management. The patented process helps customers handle sewing machine needles throughout the sewing process and also provides a digital solution for documenting needle breaks.

The Groz-Beckert Academy and the Technology and Development Center (TEZ) jointly presented their cross-departmental service program. This unites diverse training courses, test services and joint developments under one roof. With customer-oriented standard solutions or individual offers, suitable solutions are found for a wide variety of requirements.

Compact single-head embroidery machines by Happy Japan

Compact single-head embroidery machines by Happy Japan

HappyJapan’s core technologies are centered on mechatronics and applied in various areas from consumer use to industrial use, to create numerous distinctive products. All its products are produced in an integrated manner from idea developments through technical supports. The company is enhancing our R&D organization and undertaking academic-industrial joint development with outside research institutions in order to establish next-generation core technologies to venture into new fields.

HCH Series: Compact single-head embroidery machine

HCH series machine has been released as small single head embroidery machine for entry levels to semi-professionals. Easy threading, a touch screen control panel, and 100 ready to use embroidery designs enable users to kick-off their embroidery works without any confusion. The machine has a compact and light body with decent embroidery speed, including all professionally required automatic functions such as thread break detection, colour change and thread trimming. This user-friendly compact size table top machine is suitable for all kinds of apparel shops.

Main features

• Colour LCD touch screen control panel • Single head 7 colours • Maximum speed 1,000 r.p.m. • Tubular Embroidery Area: 285 x 290 mm • Low-profile cap frame(option): 67 x 180 mm • Wide cap frame(option): 67 x 290 mm • Free PC connection software • LAN/Wi-Fi and USB network port • USB memory stick port • Ready to use 100 embroidery stock designs • Easy threading • Take up lever safety guard • Automatic thread trimmer • Automatic colour change • Automatic thread break detection • Built-in bobbin thread winder

Coloreel returns with revolutionary instant thread coloring unit

Coloreel returns with revolutionary instant thread coloring unit

In 2017 Coloreel won the prestigious Texprocess Innovation Award for outstanding new technology. This edition they returned to the fair with the world’s first digital instant thread coloring product, the Coloreel unit, fully industrialized and available to the market. The Coloreel technology enables high-quality instant coloring of textile thread while in the textile production. The first product based on this technology is the Coloreel unit that works with any existing industrial embroidery machine. By instantly coloring a white base thread during the embroidery production, Coloreel enables complete freedom to create unique embroideries without any limitations in the use of colours.

At the Coloreel stand, visitors experienced live demonstrations of the revolutionary thread coloring unit, producing uniquely colored embroideries never seen before. Coloreel also explained how the technology and process work by showing the inside of the unit. “Coloreel received the 2017 Texprocess Innovation Award for its instant thread coloring technology. Consequently, it is delighted that the company is making such an extensive presentation of its innovations at Texprocess. This shows that Coloreel identified a market potential and succeeded in developing a successful and marketable product,” says Michael Jänecke, Director Brand Management, Technical Textiles and Textile Processing, Messe Frankfurt Exhibition GmbH.

New embroidery designing software by WILCOM

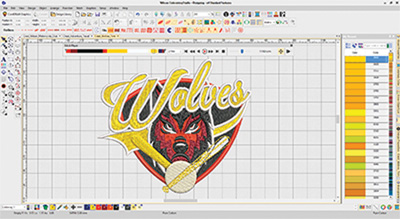

A leading provider of innovative, quality embroidery solutions for over 40 years! In 1979 Wilcom’s founders shared a vision for automating the embroidery industry that has changed the way people create and produce embroidered goods. A global organization headquartered in Sydney, Australia, Wilcom has led the industry with ongoing innovations that push the boundaries of creativity in personalized expressions and apparel decoration. The latest release of Wilcom’s EmbroideryStudio e4 suite has been a resounding global success. Incorporating CorelDRAW Graphics Suite for a complete multidecoration solution, it has proven its tagline “Creative by nature. Efficient by design.”

A leading provider of innovative, quality embroidery solutions for over 40 years! In 1979 Wilcom’s founders shared a vision for automating the embroidery industry that has changed the way people create and produce embroidered goods. A global organization headquartered in Sydney, Australia, Wilcom has led the industry with ongoing innovations that push the boundaries of creativity in personalized expressions and apparel decoration. The latest release of Wilcom’s EmbroideryStudio e4 suite has been a resounding global success. Incorporating CorelDRAW Graphics Suite for a complete multidecoration solution, it has proven its tagline “Creative by nature. Efficient by design.”

EmbroideryStudio e4 Designing

Ultimate Embroidery & Multi-Decoration Software for professional digitizers, embroidery shops, industry trainers and educators, and apparel decorators. With new technical and creative stitching effects, even faster digitizing and over 200 professional embroidery fonts, you can digitize more creative advanced designs quickly with full professional control. CorelDRAW® Graphics Suite is included, fully integrated and provides full vector and bitmap graphics software for multidecoration, printing, cutting, engraving and more.

CorelDRAW® Graphics Suite – World’s #1 Professional Graphic Design Software for Embroidery

CorelDRAW® Graphics Suite provides full vector and bitmap graphics software for multi-decoration, printing, cutting and engraving designs. Run CorelDRAW fully integrated with EmbroideryStudio e4 Designing or Decorating, or standalone. It can be configured to use an Adobe® Illustrator® style user interface.

Open and edit popular vector and bitmap graphic design formats e.g., Corel .CDR, Adobe .AI, .PDF, .EPS, etc. Convert graphics into embroidery by auto or manual digitizing. Convert selected embroidery objects into vector or virtual embroidery bitmap graphics. Switch back and forth between Corel and Wilcom windows. Save everything in the Wilcom .EMB design file. CorelDRAW is the industry’s choice for screen printing, DTG, heat press and more! With its content-rich environment and professional graphic design, photo-editing and website design software, you have everything you need to express your style and creativity with endless possibilities.

TREVIL presents finishing equipments

Trevil designs and manufactures professional ironing equipment and electric steam generators for industrial use. Founded in the early ’80s, the company is among the top ten international manufacturers of professional ironing systems. With a network of over 150 exclusive importers around the world, its products are sold worldwide successfully. Trevil products are technologically innovative, with exceptional quality and meet the highest European standards.

Pantamat 5307 – Topper for denim trousers

Pantamat 5307 – Topper for denim trousers

Powerful Pantamat 5307 provides strong and efficient finishing thanks to the 1,5 kW (2HP) motor and to the 900W steam superheater. This machine is perfect for sizing: The tensioning device is more powerful than regular toppers, moreover, the carriage is able to add tension to the leg during steaming. Waistband and leg size selectors are provided as standard.

Accurate: The strength of waistband expanders and leg tensioning carriage can be fine adjusted by means of knobs on the front of the machine. The antistretching device prevents deformation of elastic denim and can be quickly activated by means of a button on the console. The device can be independently used for waistband, leg length or both to allow for finishing of single-direction stretch fabric.

Versatile: The finishing cycle is controlled by the Trevil programmer, which is rich in functions but easy to use: up to 9 programs can be stored into the computer and all frequently used functions are quickly activated by means of a button on the console. Each program stores finishing times, exclusions, finishing modes and special parameters that can be used to customize and fine tune the cycle. The cuff clamps can be used outside in to clamp trousers or inside out for fabrics that cannot be pressed (e.g. corduroy). The function of the clamps is easily selected by means of a button on the console. A water spray gun is available as an option to improve the finish of particularly wrinkled areas.

Treviform 5123 – Tensioning form finisher for all jackets and coats

Treviform 5123 – Tensioning form finisher for all jackets and coats

• Effective: The Treviform tensioning form finisher is the top-quality choice for jackets and coats. An accurate tensioning system guarantees superior quality of finishes, reducing touch-ups to a minimum, for high productivity without compromises on quality.

• Immediate: The machine is comfortable to use and simple for any operators to run. The control board is clear and intuitive, with pre-set programs for quick start-up. The machine is activated by means of a single pedal.

• Versatile: Standard “anti stretch” device that forms the shape of the garment without it overstretching; Optional all-steam iron for touchups directly on the finisher; Optional pneumatic clamps for side vents; Allows to finish small size or fitted ladies jackets; Optional electronic adjustment of blowing power

Richpeace Automatic Cutting and Embroidery Machines

Tianjin Richpeace Computer & Machinery Co., Ltd has three wholly owned subsidiaries: Shenzhen Richforever Cad/Cam Co., Ltd (CAD software), Tianjin YingRuian Technology Co., Ltd (CAM software), Tianjin Richpeace Trading Co., Ltd (import and export). The company is located in Tianjin Baodi economic development zone.

Richpeace 1 cm Mega-size Multi Layers Automatic Cutting Machine

Richpeace 1 cm Mega-size Multi Layers Automatic Cutting Machine

Description

• Cutting blade is made of diamond hardness stainless steel, equipped with automatic sharpening device

• Cutting blade change cutting speed automatically, automatic side cut compensation, ensure quality of final markers

• The automatic sharpening device performs blade sharpening automatically, keeps cutting blade always in tartness condition, extends working life of cutting blade

• The cutting head with cutting blade is specially designed, made by extraordinary stainless steel, automatic Cleaning System

• Full protection shield system, can be manually emergency stopped anytime

• Segment adsorption and cutting, realize tailoring, pick up materials, materials with simultaneously, no cutting blind angle, there were no cutting phenomenon

• Meet the requirements of personalized clothing production, the compatibility with any clothing CAD software, high precision, long service life

Richpeace Computerized Mixed Coiling Embroidery Machine

Richpeace Computerized Mixed Coiling Embroidery Machine

• Alternative embroidery machine type: It enables to select flat embroidery or coiling embroidery automatically with high efficiency

• Adjustable zigzag device: The stitch length can be set up on the operation panel from 6mm to 16mm, to avoid the collisions with needles during thick rope embroidery

• Easy change of coiling feeding devices: different type of feeding device on the coiling heads can be changed by hand very easily

• According to material thickness, presser foot lifting adjustable range is 0-6mm

• Automatic stitch data creation of zigzag devices: the 6 types of zigzag stitches can be processed in flat embroidery stitch data, so it is easy to create zigzag stitch data

• Flat embroidery or coiling embroidery or laser cutting or sequin embroidery can be alternative

Macpi Belt Fusing Machine and Tunnel finisher

Macpi, founded in 1961, is a worldwide leader in manufacturing highly technological machines for garment industry following the tradition of Made in Italy with a constant research in terms of quality, style and innovation that cannot make compromises with a downward policy. The accrued experience of almost 60 years brought Macpi to produce greatly sophisticated automatic units for thermo- fusing, loading and unloading system, complete line for the intermediate and final finishing of jackets, coats, jeans, knitwear, trousers, shirts, automatic machines for stitch-free applications and special units for industrial laundries.

341.00 – Continuous Belt Fusing Machine

341.00 – Continuous Belt Fusing Machine

Continuous Belt +Fusing Machine, split in the following sections:

Features

• Cold loading belt with inverter control

• Length 1100 mm

• Fusing heated area with no. 2 cylinders drive

• Length 1000 mm

• Unloading belt with inverter control

• Length 1060 mm

• The machine is already adapted to be connected with the automatic loader Mod. 985 and unloader Mod. 978

• Useful working area: 1000 mm

• 7″ colour terminal TCW for parameters setting complete with USB port and Wi-Fi connection. It is also adapted to control by video the loading and unloading devices

• Automatic switch off

534 – Tunnel finisher

534 – Tunnel finisher

Continuous module-type tunnel for garments finishing. In function of its composition and the type of work to do, it can produce from 500 to 800 pieces per hour. The tunnel is composed and complete with:

• An automatic right load station for single garments complete with garments lack signal; and an unload station

• Variable-speed chain conveyor (controlled by an inverter) with hooks spaced out at 317 mm. intervals

• One steaming chamber

• One variable-temperature ventilation chamber and variable capacity through inverter

• Steaming quantity regulation

• Steaming humidity adjustment

• Garments falling signal

• Pillows for steam containment in the steaming chamber

• Programming and regulation with TCW “7 programmer

Tajima present Flat embroidery machine

Since its foundation in 1944, while building a trustworthy relationship with its customers by offering them high technology and elaborate service. While carefully protecting the TAJIMA Heritage, the TAJIMA group responds to the times with the power to give new solutions and it keeps on evolving with the times. TAJIMA, have provided over 3,000 embroidery machine models to our customers in over 100 countries around the world.

Since its foundation in 1944, while building a trustworthy relationship with its customers by offering them high technology and elaborate service. While carefully protecting the TAJIMA Heritage, the TAJIMA group responds to the times with the power to give new solutions and it keeps on evolving with the times. TAJIMA, have provided over 3,000 embroidery machine models to our customers in over 100 countries around the world.

TMCR-VF Series

Features

• DCP (Digitally Controlled Presser Foot) reduces fabric fluttering that occurs during embroidery

• FS Mode enables to embroider loosely twisted or thick thread

• Direct command switches enables various operation with one button allocated to the front of each head

• (Auto Trim & Hold / Presser Foot Switch / Customized Switch 1 and 2, etc.)

• Multi-cording device obtains a soft and fluffy feeling by using textured cord materials, and makes cording embroidery and looping embroidery possible

• Sequin Device III (Twin Type) – 2 different sequins by freely switching them at high speed / Sequin Device IV

• Seed Beads Device

• Brings you smooth finish, rich designs with sequins, normal embroidery by automatic colour change. Available with bead size dimeter 2.0mm with height 1.5mm

• Barcoding ready (Easy networking)

• Flat Type

• Needles: 6,9,12, or 15 needles

• Speed: Up to 1,100 stiches / min

Tubular and Multi-headed flat embroidery machines by SunStar

Tubular and Multi-headed flat embroidery machines by SunStar

SunStar is a leading manufacturer of Industrial sewing and embroidery machine which is located in Korea. The company provides the machine through its regional partners and do service through them.

KS-UH1506-45 – Newly upgraded tubular embroidery machine

• Max speed at 1200 rpm.

• Controlled by servo motor

• Adjustable presser foot

• New operation box(15.1 inch)

• Increased colour change speed

SB7-WH1212-65 – Newly upgraded multi-headed flat embroidery machine

• Max speed at 1200 RPM

• Controlled by servo motor

• Adjustable presser foot

• New operation box(15.1 inch)

• Increased colour change speed

Latest Embroidery solution from Barudan

Latest Embroidery solution from Barudan

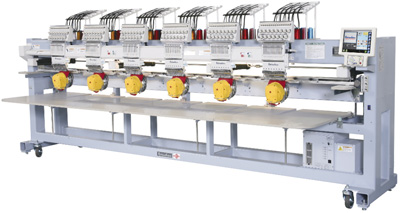

In 1959, Barudan produced the first multi-head embroidery machine in Japan. Since then, as a leader in the industry, the company has developed many products with superior value and the highest quality customer service for worldwide distribution. Today, its products are used in over 100 countries. As always its goal is to grow with its valued customers.

BEKY-CII Series – Compact Embroidery Machines

Barudan 2 through 8 head machines now have: SH embroidery head (Smart Head technology) for higher performance and increased durability, Servo motors for increased production and more power, and K automat. Barudan K Series multihead machines were introduced in September of 2016. K automat features 10.4″ Color Touch Screen, higher resolution and a 100 design, 70 mn stitch memory. User-friendly icons and an intuitive main screen provide quicker access to functions and features. It is available on all new Barudan multi-head machines. LAN and COM connectors are standard for Barudan networking along with 2 USB ports for devices such as barcode scanner, keyboard, mouse, hub and card reader.

BEKS-Y9 Series (Rotary Head – High Speed) – Multi-Head Embroidery Machines

BEKS-Y9 Series (Rotary Head – High Speed) – Multi-Head Embroidery Machines

The company introduced its newest Barudan high speed multi head embroidery machine with a maximum speed of 1000rpm. Having a LAN Connection and Networking makes Production Control easier than you ever imagined. Backed by the most advanced technology, the BEKS will change your concept of embroidery machines.

Features:

• Touch screen (10.4 inch, Resolution 800×600)

• Ability to register shortcuts into multiple groups

• Customize able display

• Easy Icon based operation

• Lan Connector Standard, 1×COM Port & 2×USB Ports, 1×Remote controller connector

• 70 mn stitch capacity, 100 memory locations

Mimaki presents latest dye sublimation printer

Mimaki presents latest dye sublimation printer

Mimaki presented the latest dye sublimation printer TS55-1800 at the Digital Textile Micro-Factory, in collaboration with the Denkendorf Institutes for Textile and Fibre Research (DITF).

The (R) evolution of Textile Printing

Designed for users that demand productivity at high quality on high speed. The TS55-1800 delivers just that. Utilized with a plotter roll for small runs or with a mini jumbo roll for long runs, the TS55-1800 grows alongside with your company.

• Continuous operation • Optional mini jumbo roll

• Possible to print on high resolution (480 x 600DPI) with a higher ink density using one-pass printing at 140m2/h

• Continuous operation with Mimaki’s Nozzle Check Unit and the Nozzle Recovery System

• Upgraded with the newest TxLink4. This dedicated textile RIP software features new functionalities and improvements on usability

• With the Optional Mini Jumbo Roll it reaches a level of productivity at market disruptive pricing

• Available in very competitive 2L packs or low cost 10L tanks, the new Sb610 ink sets allows you to grow your business profitably

• Create: Interior fabrics, sports and fashion apparel, flags, tapestry and much more…

Ironing machines by Malkan Machine

Malkan Machine is ‘Industrial type Ironing and Finishing Machine’ manufacturer since 1971, leading in Turkey and exporting to 5 continents and serving to more than 30.000 customers. We produce over 750 different industrial ironing machines and presses in Turkey since 1971 with high quality and low prices, under ISO 9001 quality system according CE norms.

Malkan Machine is ‘Industrial type Ironing and Finishing Machine’ manufacturer since 1971, leading in Turkey and exporting to 5 continents and serving to more than 30.000 customers. We produce over 750 different industrial ironing machines and presses in Turkey since 1971 with high quality and low prices, under ISO 9001 quality system according CE norms.

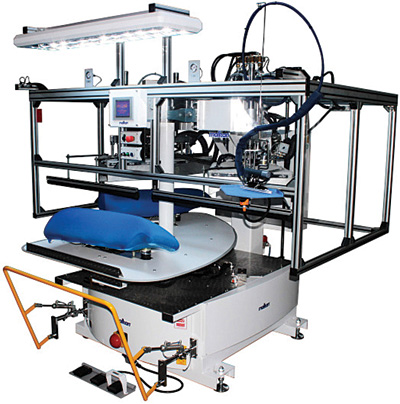

KAR1011S Carousel System Double Station Jacket Front Form Ironing Press

• PLC controlled touch screen

• Runs with central system boiler, vacuum and air

• 220V monophase

• European padding and CNC process

• Energy saving by serpentine aluminium bucks

• Vacuum and steam from upper buck

• Rating technique for steam and air at head buck

• Blowing from lower buck

• Programmable sensitive pressures adjust (digital)

• Circumference vacuum system, Easy placing with laser pointer and high ironing quality

• Circumference vacuum system, Easy placing with laser pointer and high ironing quality

• Steam amount and time adjust at head bucks

• Vacuum time adjusts at head and lower bucks

UPP19KI Pneumatic Linear System Double Legs Trousers Line Ironing Press

• PLC controlled touch screen

• Central system • 220 V monophase

• Linear and vertical motion capability at head buck

• Sensitive buck joint as for head buck weight

• Programmable steam and sensitive vacuum on head buck

• Safety frame for operator on head buck

• Stable vacuum on left-right sides of lower buck

• Programmable rating technique for steaming and air blowing on head and lower bucks

• Antishine function on head and lower bucks ensures seperate steam and vacuum system on seam parts

New range of digital textile printing solution from Epson

Epson presented several exhibits at this year’s Texprocess. Thus, i n cooperation with the “Digital Textile Connection”, an association of different companies 1, a textile workflow with the passing on of color information is shown. At the Assyst stand, textile samples are scanned and forwarded along the production line using the DMIx Cloud and the respective solutions of the companies of the “Digital Textile Connection” with regard to color-accurate processing. Finally, at the Epson stand, were colour proofed on a SureColor SC-P5000 printer.

n cooperation with the “Digital Textile Connection”, an association of different companies 1, a textile workflow with the passing on of color information is shown. At the Assyst stand, textile samples are scanned and forwarded along the production line using the DMIx Cloud and the respective solutions of the companies of the “Digital Textile Connection” with regard to color-accurate processing. Finally, at the Epson stand, were colour proofed on a SureColor SC-P5000 printer.

Furthermore, the results of the project “New Production Models – From Digital Printing to Confection” were presented by students of the University of Applied Sciences Niederrhein, which Epson awarded for the first time last year as an external client. The team working on this project was the winner in a total of 26 participating projects. One of the students of this group, Anna Charlott Buttkus, sew a dress of the project at the Epson stand with the help of an ultrasonic welding machine from Nucleus GmbH. The pattern is printed on an Epson SureColor SC-F9300 sublimation printer and sublimated live on the stand. In this way, Epson shows a complete digital workflow for customers in the fashion industry.

Epson also participated in this year’s sustainability competition at Texprocess and produces reusable fruit bags (Design Wiebke Hüskes) made of a fabric from KREA Technische Textilien GmbH on its stand. These are also produced by a sublimation process, which does not require water and less energy than other production processes.

In industrial textile printing, the Epson Monna Lisa as an industrial textile printer was at the center of attention at Texprocess. On the basis of various exhibits, the possibilities of producing textiles in digital printing are demonstrated.

ErgoSoft RIP presents software solution for the digital printing industry

The company’s latest offering is Ergosoft RIP Version 15. Developed by ErgoSoft AG, a software company with more than 25 years of experience in creating digital printing application, ErgoSoft RIP brings highest productivity, quality control and a broad variety of colour, production controlling and automation tools to your printing facility. Combining all the benefits of ErgoSoft Tex- Print, PosterPrint and StudioPrint, ErgoSoft RIP is one strong solution addressing all the different applications in the wide ranging market of digital printing and RIP Software.

The company’s latest offering is Ergosoft RIP Version 15. Developed by ErgoSoft AG, a software company with more than 25 years of experience in creating digital printing application, ErgoSoft RIP brings highest productivity, quality control and a broad variety of colour, production controlling and automation tools to your printing facility. Combining all the benefits of ErgoSoft Tex- Print, PosterPrint and StudioPrint, ErgoSoft RIP is one strong solution addressing all the different applications in the wide ranging market of digital printing and RIP Software.

Based in Switzerland, ErgoSoft runs five subsidiaries in the United States, China, the Netherlands, Portugal and France. The ErgoSoft RIP is distributed and supported all over the world thanks to a great network of authorized ErgoSoft partners.

Amann to provide insight into future of yarn

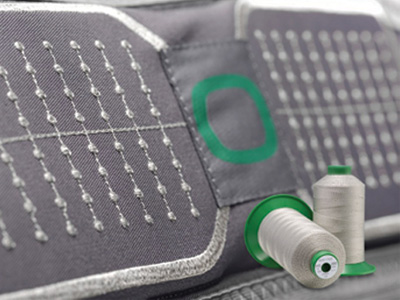

Thread specialist, the Amann group, provided insight into the future of yarns at Texprocess 2019 from May 14-17 at Frankfurt, Germany. With its smart yarns, Amann provides innovative textile solutions for areas of application that go beyond sewing and embroidery threads. Its intelligent threads can now be used as sensors or transfer media.

Thread specialist, the Amann group, provided insight into the future of yarns at Texprocess 2019 from May 14-17 at Frankfurt, Germany. With its smart yarns, Amann provides innovative textile solutions for areas of application that go beyond sewing and embroidery threads. Its intelligent threads can now be used as sensors or transfer media.

“The threads ensure a secure hold, replace plastic components or take on safety-relevant tasks: They are an essential part of ultra-modern technological products for a wide variety of industries and do far more than just perform their traditional functions in seams,” said report by Amann group. “The applications of conductive threads are wide-ranging. They can transfer electricity and data and thus provide information about the stress on components, temperature or humidity. Embroidered on car seats as touch switches or incorporated into the sole of a shoe, intelligent threads could replace raw material-intensive plastic switches and cables. This not only makes them significantly more environmentally friendly; they are also easy to process and more pleasant to grasp or wear.”

Conductive threads can also offer advantages in medical technology: As an essential component of pain relief belts, the use of Amann’s conductive thread Silver-tech enables electrical impulses to be transmitted to the nerve endings, which has a positive effect on the patient’s pain memory. Besides new fields of application, various processing methods also play an important role. The conductive Steel-tech thread, can be integrated directly into the fabric and takes on the role of an RFID antenna, recording the number of wash cycles of an item of clothing. Conductive threads can also be suitable as pressure sensors that are used in composite material recording stress data.

Not only can intelligent threads replace bulky parts in a space-saving manner, they are also particularly lightweight. This makes them attractive materials above all for future technologies such as electro mobility or lightweight construction. In particular, by avoiding materials that are difficult to recycle such as plastic and other synthetics, the threads make a significant contribution to the sustainability of components and products. “Thanks to our longstanding experience and our investments into our Innovation Lab, we consider ourselves as pioneers of forwardlooking solutions relating to threads,” said Bodo Th Bölzle, CEO and Chairman of the management board of the Amann group. “We are also proud to be part of innovations in other industries, whereby our smart yarns are crucial in showing the way”.