An aisle space can be understood as the passages left between work equipment or machines to allow free movement of people and material on the floor.

Why is Aisle Spacing important?

In factories, movement of handling equipment like trolleys and bins can be hampered if items are scattered on the floor, or machine placements clutter the passageway. Clearly marked, empty passageways, allow handling equipment to easily pass through, saving time and energy. Hence, every workstation on the floor should keep its containers within a welldefined boundary line, ensuring they do not encroach the allotted aisle space.

Also, clearly marked and empty aisle spacing provides safe pathways in cases needing emergency evacuations. Lastly, properly marked aisle spacing is a legal requirement in many countries. For instance, “Walking/ Work Surface Violations” are one of the top (Bhardwaj) violations (Occupational Safety and Health Administration, a federal agency of the US that regulates workplace safety and health). An average fine for this violation can go up to $1,632 per individual violation. As per the OSHA Standard 1910.22, all companies must mark aisle space areas to prevent accidents.

Aisle spacing guidelines

Floor markings are usually the least expensive and most preferred way for aisle space markings. But in some cases, other appropriate methods can also be used, for example on dirt floors, paint or tape on the floor wouldn’t completely serve the purpose. There are several guidelines for aisle spacing defined by OSHA:

Colour guidelines:

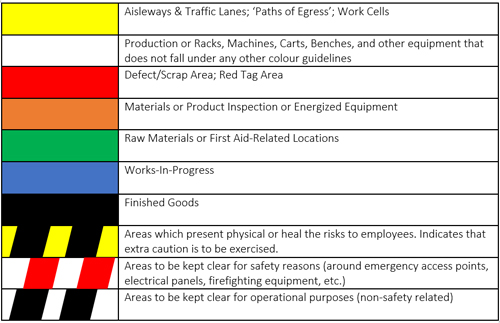

Colour specifications aren’t set by any specific law and can be modified to fit the needs of the factory. The colour guide should be posted within the factory in a conspicuous location. The following colour codes are widely accepted and comply with OSHA and American National Standards Institute (ANSI) codes interpretations:

Marking line width guidelines

Marking lines with width more than 2 inches are acceptable by OSHA and ANSI. OSHA Regulations require that permanent aisles and passageways must be marked. ANSI Z535.2 Safety Color Code designates yellow as the caution colour. This should be used to mark points depicting physical hazards like stumbling, falling or tripping points.

Painted lines tend to chip, peel and crack, especially in heavy traffic areas. Industrial Floor Marking Tapes are recognised as the most convenient and inexpensive way to mark floors, and there are a variety of floor marking tapes available to meet your specific needs.

The minimum required width depends on the utilisation of the aisle. An average width of 36 inches is acceptable in the industry. An aisle width of at least 3 feet wider than the largest equipment to be utilised should be implemented. For emergency exit points, minimum of 28 inches is the allowed width. (According To OSHA) (Source: www.creativesafetysupply.com)

Methods for Aisle Marking

Floor painting and use of industrial grade adhesive tapes for marking aisle spaces are the most preferred methods in the garment industry, due to their ease of use and low cost. The traffic and hazard level in the aisle should also be considered when choosing the method, as it affects the effective life of the marking.

Lastly, developing detailed location plans before dedicating space to aisles is necessary to ensure free aisle spaces. To avoid any confusion on the floor, factories should use as few colours as possible and simple and bright colours are the best for this. Workers should be trained not to cover the factory’s access doors, electrical outlets and important equipment with floor markings. Also, colours and patterns too close to existing safety markings should be avoided.