According to a recent data, the urban dwellers make up 18 per cent of the country ’s population and the migrations into cities is expected to continue due to the job opportunities created by the garment factories, and subsequently textile process industries will lead to more burden on energy demands.

These biomass energy demands by urban dwellers have in the past traditionally led to forest and land degradation.This situation get more aggravated by the new demand from textile process industries those who use agro waste/ wood fired boilers. The timely intervention by Ethiopian Government seeks to target 17,000 hectares of land for afforestation, thus helping Ethiopia sequester significant greenhouse gas emissions created by the textile industries.

The COMPOST programme initiated by the Ethiopian Government which will be implemented over the period of five years (2017-2021) will support Ethiopia’s ambition to build a carbon neutral economy by helping the country to strengthen national capacity to monitor and report on reductions in carbon emissions.

My deep sense of benignity as a responsible citizen of an age old traditional country propelled me to participate in this initiative within my capacity to support this movement. Since Ethiopia is striding towards industrialization to attain a status of middle income country by promoting garment and textile industry, could prefigure the amount of pollution and the depletion of finite natural resources associated with it to achieve the target. This prods me to work in this platform and do the best which could impede the ascending of these atrocities.

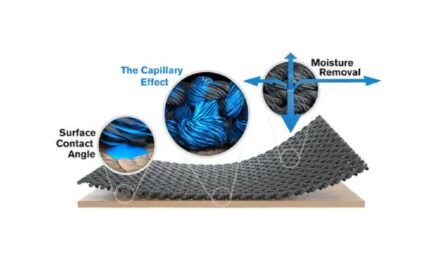

Textile industry is one of the major areas having importance throughout the world. However, off recently, the industry has been the epicenter of a massive pollution problem, worldwide. Water pollution is the main issue, when it comes to textile industry as it is a voracious consumer of water. The water is used for various processes like sizing, scouring, bleaching, dyeing, printing and other finishing processes for the woven and knitted fabric. There are varies stages where substantial quantities of water for denim/ garment wet processing and finishing are consumed.

Since being a pioneer in supply of water treatment chemicals to Ethiopia, I was well aware of the effluent pollution and the reason associated with high TDS, BOD, COD and other parameters, which again induct lot of chemicals to the system to subside the intensity of it. Mainly pollution in the textile waste water comes from the massive usage of inorganic alkalis like caustic soda, soda ash, halogenating products like salts, and the surfactants and polymers like wetting agent, lubrication agent, demineralizing agents, soaping agents etc. Due to the lack of technology adaptation by the reluctant industry to find safe and sustainable alternatives for such atrocious pollutants, I focused continuously on cheaper inorganic products and reagents, which resulted high water consumption and heavy pollution.

I found my kosher in Atlantic Care Chemicals products, to substitute all the indigenously used inorganic and hazardous chemicals in textile industry by sustainable ZDHC (Zero Discharges of Hazardous Chemicals) which can potentially eliminate all the above said pollutant category chemicals. Atlantic, being the first company in Asia having complete range of products certified by Green Screen (TOX, Washington, USA), US EPA safer choice program, ZDHC, GOTS version.5 which are the world’s highest standards endorsing a product line, which is safest to use for persons as well as environment.

I am proud and privileged to introduce Atlantic Care Chemicals to Ethiopian textile industry, which will strive hard to bring in sustainable and most cost efficient solutions. This will help in bringing up the industry which can potentially support my governments’ low carbon foot print goals. There is not so benign uncontested assumption that anything sustainable, organic, ecofriendly will be expensive to use and will not be as effective as conventional products. Atlantic will be an option for me to disprove them and can thrive business with the model people- planet – profit.

Initially, we will start with having sufficient stock of the products pertinent to garment and textile wet processing, and will create effective supply arrangement for all the zones. Bonded warehouse is an option for tax free access to these sustainable products. We will also provide highly trained technical personals from abroad to skilling the industry with most modern method of process and consistent quality.