Ramsons is India’s largest manufacturer of commercial laundry, dry cleaning and garment finishing equipment. It has a proud Indian heritage, which gives it a single minded focus to provide the highest level of customer service. With some of India’s leading companies as its suppliers, strong engineering talent and stringent quality control systems, it manufactures high quality products that are exported globally.

New Generation Vertostar (Series 7.7)

Saving Energy, Water and Space! Ramsons vertostar series 7.7 have been designed and built with a vision of operational efficiency and success of the laundry. These machines have been working smoothly all day satisfying intense requirements of the modern fashion industry. A well thought out robust design and use of best input materials ensure longevity and trouble free operation. Customization of the machine to suit specific customer requirements and excellent after sales technical support makes Ramsons a pioneer in the laundry industry. With continuous innovations, we offer the latest to minimize the water requirement and reduce the effluent for a cleaner world.

Special features for Vertostar machines

- Variable speed inverter drive with 6-40rpm for washing and 80-100rpm for pre extraction. The garments while unloading will not have much water; hence washing area will be dry and clean

- This machine has a microprocessor based programmer to control different cycles of the dyeing programme like timing, temperature, dosing etc, it can store up to 99 different programs each with 100 steps. Also the control panel has manual over ride wherein it can even work on manual mode. The control panel can also be provided with an AC for cooling as an option for places with high ambient temperatures

- The machine is provided with a circulation pump fitted through an online fitter unit. The dye bath is filtered and sprayed inside the drum at pressure through a special tri planar flat stream nozzle which reduces the liquor ratio to 1:2 To 1:3 and also improves the wash process

- The machine is provided with dual drain which can be opened depending on the process cycle. This feature will reduce the load on ETP by diverting the water from Rinse cycle to separate collection tanks which can be reused after simple filtration

- This machine has 2 nos of pneumatically operated valves for water inlet. And an additional inlet can be provided to use fresh water, hot water or even recycled water. An additional 3 water inlet can also be provided

- The geared motor is mounted on top of the machine and the Depth of the machine is reduced by 300mm

- This machine is provided with PH testing port and sampling port on the main door. The sample door is provided with a LED light to see the wash process

- This machine is provided with Hydraulic operated tilting for easy unloading. Also it can be provided with an optional stone separator. This can be easily mounted on the door opening and the stones are separately unloaded in to a trolley after stone wash saving time and labour

- The machine has all safety interlocks like motor overload, door limit switch to stop the drum rotation when sample port is opened, sensor to ensure the door is not opened when filled with water door level

Optional features for dyeing

- Controlled indirect heating and cooling system. The machine will have stainless steel (SS) heat exchanger coil for both heating and cooling with pneumatically operated control valves, the heating gradient can be programmed through the PLC up to 6 degree per minute. This system can also be programmed for controlled cooling of liquor bath

- For special purpose the tanks can be extended to 5 tanks with additional cost

- This machine has specially designed wedges to ensure minimum beating of the garment. This feature will allow the garments to oscillate in the water without any beating and abrasion for delicate garments

Go Green

Innovations for the future

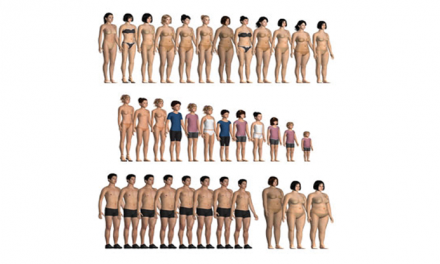

Conventional technologies seek the utilisation of huge amounts of water and chemicals during the process of fabric finishing. The quantity of discharge produced whilst this procedure is also high and harmful. Inspite of the ill-effects, these procedures have remained untouched since decades due to the lack of a reliable alternative. The latest innovation of Ramsons – Go Green Technology is a greener and earth – friendlier alternative for the fabric finishing and is undoubtedly an innovation for the future.

Features:

- Water savings upto 95 per cent

- Chemical savings more than 60 per cent

- Zero discharge

- No Cost of E-Fluent Treatment

- This unit can be connected to existing washer

Processes

- Softening

- Resins for 3d effects

- Wrinkle free

- Water repellence finishes