Golden Laser designs and builds CO2 laser machines specifically for cutting, engraving and perforating of fabrics and textiles. Our laser machines have the ability to cut fabrics and textiles into sizes and shapes efficiently and sustainably on large cutting scales, as well as cutting complex internal patterns on smaller cutting scales. Laser engraving textiles and fabrics can achieve incredible visual effects and tactile surface structures.

Golden Laser designs and builds CO2 laser machines specifically for cutting, engraving and perforating of fabrics and textiles. Our laser machines have the ability to cut fabrics and textiles into sizes and shapes efficiently and sustainably on large cutting scales, as well as cutting complex internal patterns on smaller cutting scales. Laser engraving textiles and fabrics can achieve incredible visual effects and tactile surface structures.

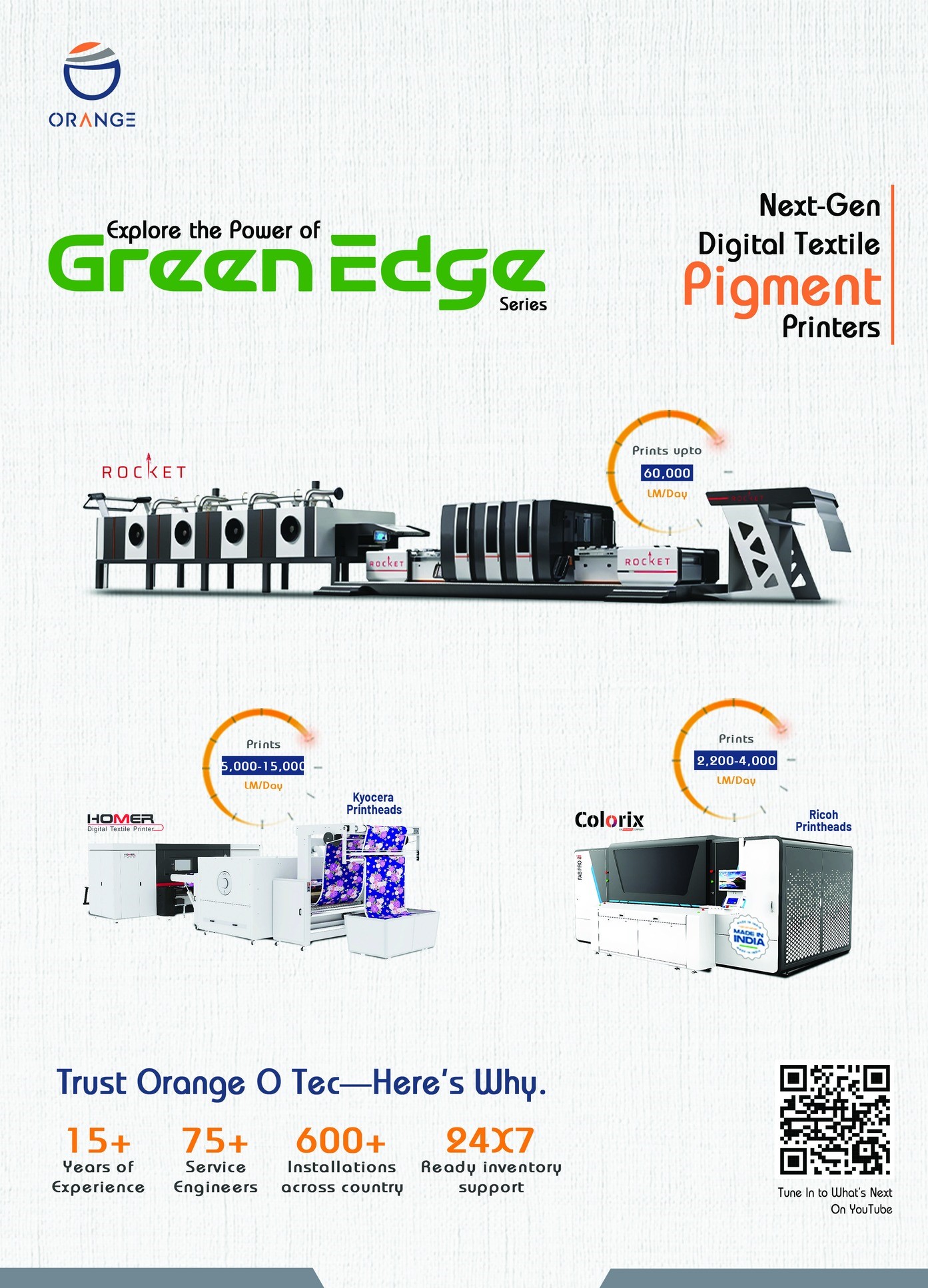

Nowadays printing technology is widely used in a variety of industries such as sportswear, swimwear, apparel, banners, flags, and soft signage. Today’s higher production textile printing processes require even faster-cutting solutions.

What is the best solution for cutting printed fabrics and textiles? Traditional manually cutting or mechanical cutting has many limitations. Laser cutting becomes the optimal solution for contour cutting of dye sublimation printed sublimation fabrics and textiles.

Golden Laser’s vision laser cutting solution automates the process of cutting out dye sublimation printed shapes of fabric or textile quickly and accurately, automatically compensating for any distortions or stretches that occur in unstable or stretchy textiles.

Cameras scan the fabric, detect and recognize the printed contour, or pick up the printed registration marks and then laser machine cuts the chosen designs. The entire process is fully automatic.

The advantages of cutting dye-sub textiles with our vision laser system

- Precisely and delicately cutting directly from roll

- Easy to operate – Automatically recognize the printed contours

- Flexible processing – Any design and any order size

- Fusion of cutting edges – Thermal processing polyester fabric

- Contactless processing – No fabric distortion

- The main application industries of digital printing textiles suitable for laser cutting are Sportswear, Activewear, Labels & Patches, Fashion and Home Decor