Indian garment exports has clocked 18 per cent growth since January 2017 after having remained stagnant for past three years and we hope that similar trend may continue for remaining period this year. Last year apparel exports were to the tune of $17 bn and this year growth is expected to be between 17-20 per cent from April to March 2017- 2018.The growth in exports will be supported by its expectations of increase in the global apparel trade and partly due to benefits of depreciated rupee. Moreover, the country’s emerging position as a preferred supplier for valueadded garments has significantly improved.

To cater this growing demand more effectively, new technologies play a very important role. This is the reason, why all major apparel manufactures have acknowledged the role of applying innovative techniques to help them remain ahead in today’s competitive markets. As a result, technology suppliers are striving hard to innovate and develop new technologies keeping with demands of the industry.

In its continuous endeavour to provide the industry informative content, in the next few pages we are covering some of latest technologies introduced for apparel manufacturing…

Affordable, Compact And Fast DTG Printer From Polyprint

Speedpocket by Dürkopp Adler

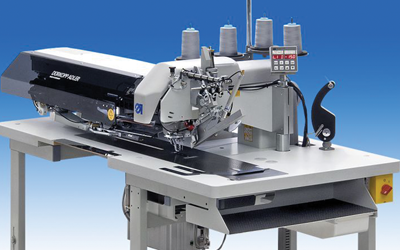

Dürkopp Adler is a leading sewing machine and process automation company from Germany. The group operates with a worldwide service and distribution network of 11 subsidiaries and more than 80 authorized dealers. The company’s latest offering is sewing unit with CNC step motor technology for runstitching of straight pocket openings 745-34S Speedpocket.

Since its introduction the sewing unit for piped pockets 745 Speedpocket has been characterized by a very good price/performance ratio and maximum productivity. The Speedpocket is perfectly suitable for runstitching of rectangular openings of piped pockets, flap pockets and welt pockets with manual feeding of all additional parts. The optionally available equipment increase performance, productivity and flexibility at maximum quality. Advantages of the Speedpocket are:

- Simple to operate – shortest training periods

- Maximum productivity

- Maximum precision of corner incisions

- Easily adjustable corner knife system, can be swiveled out for cleaning and maintenance

- Reduced bobbin change due to double bobbin capacity

- Separately lowerable transport clamps for smoothing out the material, programmable

- All pockets parameters are freely programmable

- Three laser lights for last and precise loading of the fabric

- 9 memorized sewing programmes

- Sequence with up to 7 sewing programmes programmable

The sewing unit 745-34S has been upgraded as follows:

- Difficult materials are safely held during the transport – the increased maximum pressure can be adjusted separately for the left and right clamp

- Optimized transport behaviour by means of specially balanced machine head and extremely quite running.

- Condensed stitches programmable at seam beginning and seam end

- Enlarge working area of the height adjustable machine stand up to 1,076 mm max.

- Comfortable movement of the sewing unit due to optional set of transport rollers

- Suction device integrated in the machine stand (Optional)

- The optionally available flip stacker moves according to the working height – thus, the optimum position close to the seam is always guaranteed and the processing of short work pieces is facilitated

Direct-drive high-speed lockstitch machine by Juki

Juki Corporation is one of the leading industrial machine manufacturers and ranks as the no.1 in sewing machine manufacturer in the world. Headquartered in Japan, the company currently has manufacturing facilities in Japan, China, Vietnam and markets its products in more than 150 countries across continents. DDL – 900B which is a Direct-drive, High-speed, 1-needle, Lockstitch Machine with Automatic Thread Trimmer (Oil Shielding System) is one of the latest machineries by the company.

Given are some of its features:

- Elimination of the oil stains on sewing products by Oil Shielding System

- Oiling & oil quantity checking with ease

- Broadened range of adjustment of hook oil quantity

- Highly Functional Control Panel: Equipped with highly functional control panel CP-180 for various sewing data ranging from the sewing speed to the production support functions can be adjusted, in addition panel is added with additional feature of password lock function.

- Compact & Small Energy Saving Direct Drive Motor:The machine is driven by the direct drive servo motor saves power consumption by 25 per cent in comparison of V-belt driven sewing machine

- Provided with as Standard LED

- Highly functional touch back switch

Ultra high speed & Mechtronic overlock machines by Siruba

Kaulin Mfg.co Ltd was established in 1965.Over the course of the past four decades, Kaulin has devoted itself to deliver exceptional industrial sewing machines. The company went on to introduce a whole range of machinery in the following years catering to different product lines such as knits, woven, jeans, leather goods, home textiles, jute products etc. Now it has got one of the largest range of machines in the world and is a force reckon with in the world for industrial sewing.

700L|700LD Ultra High Speed Overlock/ Safety Stitch Machine

Given are some of its highlights:

- In pursuit of the core performance of thread controlling and fabric feeding, it realises perfect sewing quality: Threading system is fully optimized. As we fine-tuned every detail about the thread tension, it realizes a very good thread controlling. The feed dog, Presser foot, and fabric trimmer are well coherent to make the fabric feeding optimized. Regarding the applicability range of fabric weight, 700L has a more comprehensive correspondence by specification, and realizes the satisfactory seam quality

- In pursuit of mechanical precision, it realizes the stability under high speed operation: Improving the spare parts manufacturing process, the spare parts manufacturing process is improved. As the precision, surface treatment, microfinish honing and parts light weight design are strictly coordinated in details, it realizes the high speed, stable, low noise and vibration mechanical performance

- The bigger range of sewing application: Regarding sewing material thickness, we have a full specification (including gauge set, upper looper stroke, mechanical timing etc.) to satisfy customer requirement. We provide the nice seam quality in sewing fine or extra heavy material

- The high speed servo motor: By the plenty power. It realizes the operation speed of 7,500 RPM. High precision makes low noise level and low heat

- The controller modularized design, with a variety of combinations, comprehensively meets the various demands:

- Economic type: energy saving, and also drives EC device electrical tape cutter

- Multi-function type: The sensor checks fabric edge for automatic sewing mode. Also semi-auto or manual mode can be switched on demand.

- Multi-function te includes pneumatic and electrical type. Customers may choose the suitable specification according to the factory facility.

- The new sensor is more sensitive, more accurate, no blind spot

700Q series Mechatronic Overlock Stitch Machine

Features:

- The first and only design in the world, which completely integrates the electric portion (Servo motor, control box, and power switch) into overlock machine. 700Q advanced version is compatible to optional automatic devices that bring complex design to simple formation

- The new Siruba technology embedded the powerful servo motor into the main body. Due to the nice weight allocation, the machine is more balanced. The power transmission is completely performed

- The Siruba’s exclusively built-in synchronizer is now more evolved! The locator IC is integrated and sealed inside the motor which makes sensing more precisely and signal transmission with zero error. Such improvement omits the old way of signals connection, eliminates the possibility of transmission defects between interfaces, and implements system integrative spirit of design throughout

- The embedded motor which joints the outstanding transmitting system, skillfully divided the power to drive the oil supply system. Modularized oil lubrication system simplifies the assembly and user maintenance works, therefore eliminates the possibility of man-made error

- The needle bar mechanism adopts the compulsory oil-supplying to ensure the high speed movement. The needle bar lower position equipped with the compulsory oil-returning to ensure the perfect oil control status

- Compulsory oil-returning is leaded by the suction of the main shaft rotation. To combine the upper looper’s initial oil-returning system, it upgrades the lubrication system

- The newly designed integrated oil-filtering, oil-supplying, and oil-returning is easy for assemble and maintenance

- Double-lip type wiper design ensures the feed dog mechanism’s oil proof. With the new oil seal and compulsory oil returning, it realizers the clean sewing bed

- Smart and unique design is due to Siruba’s mission to all users and the insistence of excellence.

- The built-in vortex fan blades cleverly use the extra power generated by the running motor to suck the external air into the motor to cool it off directly. It divides two air flows that go into oil tank and control box individually to exert the cooling function and significantly prolong each and every part of machine life of usage

- It is usually not easy to inspect the oil amount with the under-located oil monitor. It is almost incapable to tell the oil amount especially when lubricating oil turns dark after times. 700Q, however, was redesigned the location of oil monitor to a higher position that avoid any inspection difficulty completely.

- The power switch is integrated to the machine body side and the built-in LED light can indicated the power on or off status clearly. With those humane designs, the safely of sewing environment is secured.

- Newly designed integrated LED light is compact, elegant and power supply by 700Q control box. The transformer and adapter are not required. The new designed base is same as interlock sewing machine, which is with easier installation and better balance.

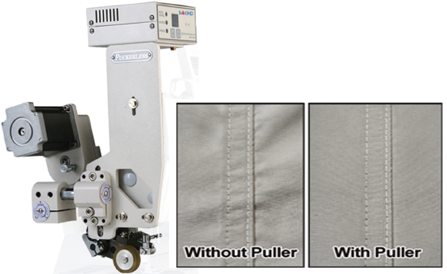

Digital Puller by Sakho

Sakho Technocraft Pvt. Ltd. is providing sales & service of Korean make Sakho Brand Special type industrial sewing machine & attachments. The company provides best machineries and service to garment industries with its highly dedicated technical & commercial. Its automated garment machineries & attachments are well known across the world for its low cost, best quality, durability, outstanding performance & services.

The company has modified and specially designed its Digital Puller (SAKHO Model EJ-9) for Brother Model S-7300 A. Now its Digital Puller is running without Synchronizer. It has one more advantage in the Digital Puller, i.e. when operator does back tacking the Puller roller rotates in reverse direction which is not possible in mechanical Pullers.

Also noteworthy is that the Digital Puller is very popular in Home Textiles, because the same puller can be used in single needle, double needle, zigzag, multi needle and overlockany brand machines. (For Overlock machine we need some additional attachments). The customers who give more preference for the seam quality they all use its Digital Pullers in their Production. Also many of the top quality formal shirts & trousers manufactures use its Digital Pullers to avoid puckering and give better seam quality.

Cutting and spreading solutions by topcut-bullmer

topcut-bullmer is the supplier of innovative cutting technology and is one of the leading international companies in this sector. The technology by topcut-bullmer stands for trend setting manufacturing solutions which deliver the highest levels of efficiency and productivity. topcut-bullmer serves the entire process chain not only with the machinery, but also with the design software, consulting and other services

Powerful Cutting: PROCUT 1800 Efficiency

Effciency in mass-production: The PROCUT is the automatic cutter for producing large quantities. Available in cutting heights of 50mm or 80mm (compressed) depending on type of material. Features at a glance:

- Easy programming and change of cutter parameters

- Besides cutting, optional drilling and marking

- Great operational flexibility

- Programming of simple pieces directly on the cutter

- High precision cutting for more productive sewing

- Operator friendly handling & menu navigation

- Entry into professional cutting

- Convincing cost-performance ratio

- Cost-efficient production

- Increased productivity

- Little space requirements

- Easy to operate

- Intuitive operating system

- Unlimited flexibility for part-shapes

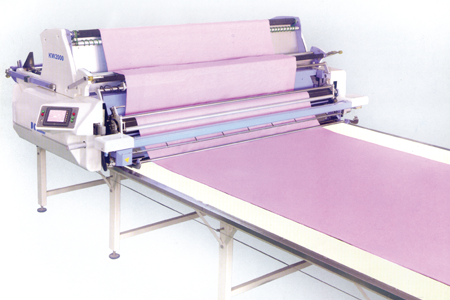

KW2000 Automatic Spreading Machine

Given are some of its highlights:

- Touch panel display: Easy to set up the length; number of layer, speed and steps

- Fabric expanding device: It can be adjusted according to the different width and tension of fabrics making fabrics free from tension

- Cutting device: The auto cutter can be easily dismounted

- Catcher: Can work for both one way and face to face

- Automatic fabric relaxing control: To relax the fabric in advance and release the tension during spreading the fabric

- Fabric leading sensor: Machine returns back to original position once fabric runs empty

- Automatic lifting device: It is automatic lifting according to the layer of cloth during spreading the fabric. The lifting gauge can be adjusted

- Emergency stop: The brake lines are under two sides of table, it can efficiency pulled upon emergency

Features:

- Machine returns back to original position once fabric runs empty.

- The machine power will automatically shut off upon 5 min. idle.

- The spreading laid fabric is not pulled when the emergency stop triggers.

- Automatic fabric expanding systems

- PLC touch panel, user-friendly operation system

- Non-tension spreading

- Simple operation increases production efficiently and also ensures the best quality.

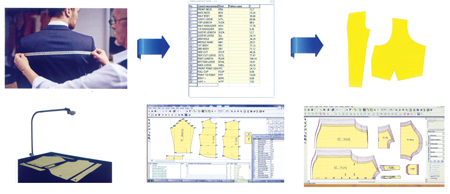

Apparel CAD Solutions Software by Orbito

Orbito Asia Pte. Ltd., Singapore came into existence in the year 2000. It was established in order to cater to the needs of the sewn product industry in the South Asian region. It has a wide range of machinery with the most advanced features. The range of products include band knife cutting machines, straight cutting machines, thread trimming machines, cone winding machines, sewing machines, embroidery machines, finishing equipment, CAD systems, packing equipment and many other allied products required by the Sewn product industry. Given are the features of its latest Apparel CAD Solutions Software:

- Fast and easy to use

- Accurate fit to the measurements

- Reshape patterns easily

- Easy retrieval of old patterns

- Automate any type of garments like mens, womens & children’s T-shirt, shirt, trouser, suit, blazers, etc.

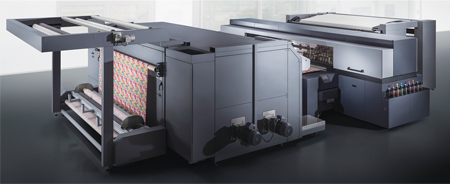

Affordable, compact and fast DTG printer from Polyprint

Polyprint S.A. is a family run business that specialises in solutions for digital textile printing with its core business being the manufacture of Texjet® DTG (Direct to garment) digital printers which are now being sold in 55+ countries across five continents. Based in Thessaloniki, Greece, an area with a long history in the field of textile printing, home to numerous T-shirt printing companies, most of them experts in high fashion T-shirt printing. The company is represented by Cheran Machines India Pvt Ltd in India.

Tex Jet Plus® Advanced direct to garment printer is one of its latest offerings. It is the only B2B printer that can stay idle up to 30 days with zero ink waste. It has lowest real running cost and comes with print head warranty. Given are some of its highlights:

- Printing Size: Max 42X60cm (16.5×23.6)

- Printable: Cotton, polyester, cotton/polyester blends, linen, viscose

- Textiles: Leather & more

- Printing: 360×360, 360×720, 720×720, 1440×720, 1440×1440 dpi

- Resolution: Multiple combination possible (Ex. 1440x1440W x 720×720-CMYK)

- Printing Head Type: Dx7.8 ink channels, 180 nozzles per channel

- Head Height – Stepless auto adjustment / Max 25mm (1inch)

- Printing Speed – High Speed Mode: 60 white / 20 dark t-shirts/hour (based on A4 image size)

- Inks: Waterbased textile pigment CMYK + White

- Ink Feeding: Pressurized Refillable ink cartridges

- Connectivity: USB 2.0, Ethernet 10/100

- Operating System: Mac OS, Windows XP, Vista, 7,8,10

- Power: AC 230V, 60W

- Dimensions: 128x70x51cm (LxwxH)

- Operating Condition: Temperature 10-25ºC/ Humidity 50-80 per cent RH

Cheran’s Digital Oval Textile Printing Machine

Cheran Machines India Pvt. Ltd., an ISO 9001 – 2000 certified company and a pioneer in garment/ textile printing machineries is located in Coimbatore, Manchester of South India. With a strong commitment for quality, it has built strong brands recognised for innovation, user friendly features and superior performance for the past 14 years. The Digital Oval Printing Machine (Pigment) is one of the latest innovations by the company.

Given are the main parameters of Digital machine:

- Print heads: Industrial printing heads

- Colour: CMYK 4 colours

- Printing resolution: 600*800dpi, 600*1000dpi, 600*1200dpi

- Max printing resolution: 600*1200Dpi

- Fabric types: cotton, hemp, Silk, Nylon, Polyester, Wool, Cashmere

- Printing Height: 3-15mm

- Max printing size: 650*850mm

- Thickness of fabric: 25mm

- Ink system: Automatic negative pressure ink system

- RIP software: Photo Print, Neostampa

- Printing head maintenance: Self moisturizing, Selfcleaning, Auto ink scrapping system

- Work environment: 25-280C, 55 per cent – 65 per cent Humidity

- Speed: A4 400PCS/HR, A3 280 PCS/HR

Main Technical Variables of Oval Machine:

- Max Printing Dimension (L*W): 550 X 700 MM (Screen Printing)

- Max Station Dimension: 590 X 865 MM

- Max Screen Frame Dimension: 680 X 900 MM

- Machine Length: 12.5M, 14.25M, 16.75M, 18.65M,20.85M, 23.05M

- Machine Width: 350 CM

- Machine Height: 180 CM

- Machine Weight (KGS): 2100Kg, 2600Kg, 3100Kg, 3600Kg, 4100Kg, 4600Kg

- Overprint Precision: ± 0.02MM

- Air Pressure Specification: 0.6MPA/0.8PA (After Drying & Filtering can be used)

- Print Head Power Driver: 750W (Every Printing Head Servo Motor)

- Total Power Consumption: 7.5KW, 9KW, 10.5KW, 12KW, 13.5KW, 13.5KW, 15KW

- Production Capacity: For Screen 600 pcs/h

Direct Textile Printer by Negi

Negi Sign Systems & Supplies Co, is India’s only specialist distribution company for wide format printing industry with high quality large format printers, software’s, consumables and pre & post solutions since 1995.Negijet TX R-1900 direct textile printer is company’s latest offering. The top quality textile printing system has been innovated with uncompromising passion.

Designed especially for high quality, high productivity and high performance, the Negijet Textile Printers opens a new possibility if textile printing with state of art digital technology and customer focused approach of daily smooth operations and reliable printing. Negijet Textile Printer series is the solution for customers who are in need of high image quality, low running cost and user friendliness in order to survive intense competitive market of textiles. Features and advantages:

- Powered by Ricoh Gen5 variable dot print heads 8 print heads and 16 print heads

- Max speeds: in 8 colours; Upto 120 sq.mtr – 8heads; Upto 240 sq.mtr – 16heads

- Width available: 1900 mm

- Resolution: 300dpi / 1200 dpi with variable drop 7pl/14pl/21pl

- 8 colours – CMYK + Red, Orange, Grey and Blue

- 4 types of inks to choose: Reactive, disperse, acid or pigment.

- Equipped with best designed. Belt-transporting system, with auto brush & sponge roller washing system

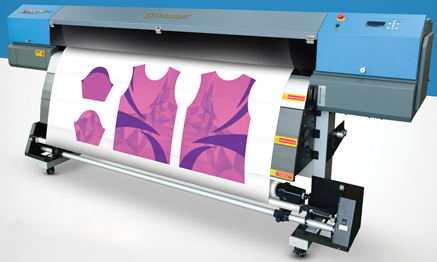

Sublimation printer series by BriteJet

Britomatics group established in 1995 is leader in providing solutions to wide format digital technology. The company provides a suite of products related to wide format technology including inkjet printers, printheads, inks and related consumables for commercial graphics industry. With significant R & D, infrastructure investment and competitive spirit Britomatics will continue to be an innovative in their product line.

E180-DX5 2Heads/4Heads Sublimation Series

- Piezoelectric picture quality

- Standard double-headed design, print, twice the speed of a single head

- Automatically receiving, feeding structures

- Infrared heating, air-dry system

- Print format 186cm, with a print before, during and after heating

- Machine-tested, stable and reliable, capable for mass production needs

Highlights:3 separate heaters:

- Pre heater: Enhance the ink adhesion

- Bed heater: Solidify ink droplet shapes

- Rear heater: Speed up ink drying

ColorJet India launches dye sublimation textile printer Aurajet

India’s biggest wide format digital printer and also a winner of several awards in the last few months, ColorJet India Ltd recently launched the Aurajet dye sublimation textile printer. The Made-in-India Aurajet, which is running successfully in Australia, Sri Lanka, Saudi Arabia and other parts of world, is the perfect choice for dye sublimation users as it can easily run low GSM paper starting from 45 GSM which will help in reducing the cost by using less ink and offering perfect colours.

The sturdy industrial built of the Aurajet helps in ensuring that the machine runs for years and years, while achieving maximum speed of 34 sq. mtr, thereby providing huge production runs. It comes with advanced feed and a take-up system for precise paper movement. The Aurajet is bundled with COLORGATE RIP to give vibrant colours and also comes with new CB100 inks, for best results in sportswear, apparel and home furnishing applications. Aurajet series II delivers Profitable Benefits:

- Maximum Print width upto 1829mm

- 4 colours ink sets for vibrant printing

- Prints on very low GSM Paper

- Highly advance take-up and feeding system

- Environment friendly

Outstanding Productivity: For large sizes such as 72’’ print width, Aurajet Series II delivers Superlative productivity at super high speed very affordably with high precision and minimum downtime.

High performance synchronized for world class quality: Maximum speed with fast & accurate take up and feeding system makes it the ideal printer for the dyesublimation printing business.

Affordable print cost: Specially calibrated to print on papers of lower GSM starting from 45GSM.Wide –body capability easily prints on larger print width media of upto 72 inches, thereby reducing the overall printing cost

Consistent vibrant print quality: For enhanced print quality and productivity, works best with CB100 Ink system of 4 colours for highly vibrant and attractive, long lasting print quality with sharp, smooth and perfect colour gradations

Continuous printing operations: Bundled with a bulk ink system that offers continuity in the printing operations

Sublimation Inkjet Printer by Audley

Zhengzhou Audley Digital Control Equipments Co., Ltd. is high-tech enterprise manufacturing professional advertising equipment from China. Its products are exported to the Middle East, Europe and America, Southeast Asia and so on more than 20 countries and regions, believe that one day, in need of advertising equipment every place in the world, there are “AUDLEY” existence. The company is represented by Tanya Enterprises in India.

S8000-3/S8000-5/S8000-7 Sublimation Inkjet Printer

The technology comes with Epson Industrial printhead 5113/dx5/dx7. Features:

- Industrial printhead: Dx5113, using the latest film piezoelectric technology, long service life

- The car frame height adjustment: Can adjust the printhead height, the convenient user more medium, according to the thickness of the material.

- Rotating platform: Humane rotating work surface, easy to operate, for customers to save space, closer human computer interaction

- Heavy industrial frame: Heavy-duty industrial airframe structure, effectively improve the image print quality

- Double servo motion systems: High power dual servo motors, precision motion control system, long working hours and more stable

- Control System: Using the most stability control systems, industrial grade optical fibre transmission, ensuring a more stable and more high speed data output

- Humane alarm device: (Alarm + LED)

Direct Printing Solution by Flora

Founded in 2000, Shenzhen Runtianzhi Digital Equipment CO., Ltd has manufacturing bases in Shenzhen, Dongguan, Huizhou, and Zhongshan almost 700 staff and plants up to 100,000m2. As a national level high tech enterprise, Runtianzhi’s products applied in advertisement label, ceramic printing, digital printing and industrial application 4 fields are widely sold in both domestic and overseas markets.

One of the latest innovations by the company is Direct Printing – Flora T-100. Given are its features:

- 8x Ricoh Gen5 industrial printhead, grayscale

- 8 colours – reactive, disperse direct, disperse transfer, pigment & acid ink

- Upto 1.8 mtr wide fabric: Cotton, linen, silk, polyester, nylon, etc

- Auto belt washing and drying unit

- High precision professional textile belt system with fabric feeding, drying, winding

Application:

- Apparel, garment, home textile

- Cotton, silk, polyester materials

- Thin fabric such as chiffon, georgette and also stretchable fabrics

Specification:

- 75 sq.mtr/hr high quality printing on fabric

Direct Fabric and Heat Transfer Printing machine by Wenli

Yiwu Wenli Imp.& Exp. Co., Ltd. is one of the 10 biggest export companies in Yiwu, China. As one of the leading professional dealer for different kinds of textile machines & spare parts for many years, it is the largest exporter for needle loom and zipper machinery in China now. The company also offers printing machines for various segments.

1.9 T-Series Direct Fabric Printer

- Model: TT-19P4_R_F

- Print head: Epson_PC3200

- Number of print head: 4

- Resolution: 1440dpi

- Colour number: 4 colour

- Speed: 2pass: 130m2/h 4pass: 80m2/h

- Print width: 1.09M

- Ink: Reactive/Acid/Pigment

- Operation Environment: 15ºC-30ºC-50 per cent – 75 per cent

- Power: 50hz/60hz 110V/220 25A

- System: Window 7

- Media Type: Cotton/Polyester/Non-Woven etc.

- Image format: Bitmap, tiff, jpeg, eps, pdf

- Weight: 800kg

- Takeup system: Optional

- Machine dimensions: 2.8M (L)* 1.9M (W)* 1.33M (H)

- Packing dimensions: 3.2M (L) * 2.17M (W)* 1.43M (W)

WL 50/90 Heat Transfer Printing Machines

- For roll to roll or piece by piece fabric, this is rotary drum type, printing is continuous & speed is much faster than old plate type technology

- This machine is equipped with Blanket release system which means when machine is out of power or printing job is complete, we can directly shut down the machine without waiting for temperature drop. Other machine, the workers have to wait for 1.5-2 hours

- This machine is equipped with PID temperature control system which keeps the temperature constant with ±2ºC and save the energy by 50-60 per cent during the production process.

Large Format printer by Epson

Epson Italia S.p.A., an Epson Group company, has acquired For.Tex S.R.L., a leader in the textile printing industry. Epson Italia, which purchased a 50 per cent stake in For.Tex in 2012, completed the buyout in a move that strengthens Epson’s digital textile printing business. Epson expects the digital textile printing market to grow at an annual rate of about 25 per cent going forward. The acquisition of For.Tex immediately gives Epson know-how across the entire textile printing process, from strategy and design through manufacturing and sales. This knowhow, along with unified management, will enable Epson to further accelerate growth of the textile printing business.

Large format printer SureColor SC-F2000

The next big thing in T-shirt printing. Discover the revolutionary direct-to-garment printer from Epson. Engineered with Epson’s micro Piezo TFP print head and Ultra Chrome DG ink technology, The SureColor SC-F2000 delivers quality, versatility and reliability for direct-to-garment printing. Product specifications:

- Printing solution: Direct-to-garment printer, Garment creator software included

- Print area: 356x406mm (14x16in) standard print area (Max printable area 406x508mm(16x20min)

- Printhead type: Micro Piezo advance TFP

- Print speed: Dual CMYK colour mode: 27sec (default – production)

- Single CMYK colour mode: 50sec (default – high speed), 104sec (high-quality) CMYK+ white mode: 88sec (low white ink density), 171 sec (high white ink density) 111 sec (default)

- Max. resolution: Colour 1440x720dpi, white 1440x1440dpi

- Droplet size: 21pl (Standard size)

- Ink type: Ink cartridge capacity – UltraChrome DG ink (600ml/250ml)

- Media: 100 per cent cotton2 or blended materials with a minimum of 50 per cent cotton2

- Conductivity: Rear – USB2.0, 100-baseTX Front- USB memory slot (USB2.0)

- Power supply: AC 100-240V 50/60hz

- Supported OS: Garment plugin – Windows® XP-32bit, Windows® 7-64bit, Mac OS 10.6 or higher Adobe®plugin – Plugin available for Adobe Photoshop® and illustrator®

- Dimension: WXDXHW – eight – 985×1,425x490mm, Approx. 82kg

Mixed Chenille with Taping machine by Textile Technologies

Textile Technologies were established by a team of very experienced embroidery & International Trade processionals. Company has always made its name felt in the North Indian market as a prominent supplier of specialised embroidery machines. Textile Technologies has established itself as the most trusted supplier of embroidery products.

Most importantly, it has popularized the concept of computerized Aari embroidery among shawl/stole manufacturers/garment and home textile manufacturers in North India. It is the first one to run successfully the chain stitch machines, alongside its regular expertise in sequin & cording embroidery machines. Having major presence at Delhi NCR and Punjab, it has established itself as a preferred supplier across North India.

The company has launched a new technology in Specialised Embroidery Machines, Machine Model: Mixed Chenille with Taping. The machine is capable of doing flat embroidery /chain stitch embroidery / towel stitch / taping with lock stitch / cording. Machine has been appreciated widely by the industry & some good orders have been booked already. It is a futuristic technology, now launched in high speed version.

Digital & Sublimation Textile Printers by JISL

Jay Instruments & Systems Pvt. Ltd. (JISL) is a leading manufacturers and provider of weighing solutions for industries and laboratories for different applications. One of the latest offerings by the company is DigiColor Digital Textile Printer and FEDAR DigitalSublimation textile printer.

D8-180|260|340 DigiColor Professional Digital Textile Printer

- Professional textile belt carrier system: Designed for tension less transport of fabric- suitable for rigid and stretchable fabric.

- Suitable to various textile dye inks:

- Reactive inks for silk, cotton, linen and wool

- Acid inks for prints on silk, wool and nylon

- Pigment inks for print on any fabric without pretreatment

- Direct disperse inks for polyester fabric

- 8Pcs Epson Dx5 heads: The printing speed is 1000 sm/day at good quality

- 1.8m, 2.6m, 3.4m wider width: Suitable for fashion and also home textile application

- Active dancing bar: Prevents weft strain on knit fabric

- 4 or 8 colours ink available: Supports CMYK+4 special colours to get wider colour gamut.

- New inkjet control system: Supports variable dot size setting, higher ink conversing volume per unit and higher product capacity

- Auto belt washing & Drying unit: Keeps belt clean and dry during continuous printing.

- 3 sets of fabric drying unit: Dries the fabric completely after printing

- All-in-one computer operation platform: For complete and smooth operation. (Computer not included in supply)

- Professional textile RIP and Print Software

- RIP Software supported – Neo stampa textile version

- Industrial textiles RIP with step and repeat

- Spot colour and special colour management

- Colour chart customization, easy creation of profiles

- Cost control utility

- Smooth management of workflow

Functions and features:

- Equipped with constant take up system: The embedded magnetic particle clutch makes sure that the media take up tension is constant and stable from the beginning to end so that print quality is guaranteed

- There are 4 Epson industrial 5113 printheads: Speed of 2 pass can reach up to 110 sqm/hr

- Dislocated carriage base plate is precision equipped which makes head position adjustment more convenient

- Gigabit data transmission port which can meet the demand of high resolution and huge file transmission to assure stability

- Name brand core parts: THK guide, NSK bearing, IGUS chain, LEADSHINE servo motor, etc., which makes FEDAR printing system stable and gives excellent output

- Integrated head cleaning and moisture capping module

Alpha series machines by Durst

Durst is the global leader in supplying digital inkjet printing systems for industrial applications. High performance, print quality, reliability and flexible areas of application are unique selling points across all the industries where Durst inkjet technology is used. Over the past ten years, Durst has had a significant influence on the adaptation of digital printing technologies in the areas of glass, largeformat printing, ceramics, labels and textiles.

Durst Alpha 190 Series – Special Features

With the new Alpha 190, Durst offers, especially for the fashion sector, various configurations in the entry and exit units to print on super-elastic knit fabrics. The fabric management allows very fast changes of the feeding roll. The Online nozzle control enables the operator to print a test stripe without interrupting the printing job so as to analyze the printing process and take immediate action should individual nozzles fail or insufficient ink be applied. This guarantees process stability. The print heads and inks are matched to one another and come from a single source. This guarantees the functioning of the overall system.

- Print speed:

1-Pass 300 x 600 dpi, 620 lm/h 1 Pass, 990 m2/h

2-Pass 300 x 600 dpi, 310 lm/h 2 Pass, 490 m2/h - Printing width and material thickness: Max. printing width: 1,900 mm, max. material thickness: 8 mm

- Material feed options: Integrated material entry for roll diameters up to 500 mm Axis unwinder for large rolls and material feed system for optimum advancement and tension monitoring Feed unit for folded textiles

- Printing blanket: With permanent adhesive and integrated washing system Heated pressing roller. Airblade for automatic belt drying

- Dryer: Horizontal dryer with 3 passages: Thermal air dryer of up to 150 °C; with either gas, steam or electricity

- Material discharge options: Uproller for roll diameters up to 500 mm Discharge unit for folded textiles; Axial unwinder for big rolls up to 2000 mm

- Print heads: 32/64 Durst Alpha Slots, 8 colours arranged symmetrically (mirrored) print heads featuring 40,960/81,920 nozzles

- Printing mode: Variable droplet size with 7/14/21 pictoliters

- Resolution: Standard 300 x 600 dpi and 500 x 600 dpi

This system is designed for non-stop production and easily produces 200m2/h. The Alpha 180 TR features a maximum print width of 185 cm and is equipped with the latest Quadro S print heads for sublimation disperse inks. Durst offers a specially formulated Dye Sublimation Ink System: Water-based, odour-free, skinfriendly and free of any volatile organic compounds (VOCs).

This printing system is classified for all current transfer papers at maximum quality. It creates brilliant colours, sharp images and produces an impressive abrasion-resistant and water-proof result. Durst also offers an optional “Direct Printing Kit” for the Alpha 180 TR, for fabrics needing deep colour penetration like flags and banners. The changeover between transfer paper and direct fabric printing takes only a few minutes, and can be easily performed by a single operator.

Features:

- Print speed:

- 1-Pass 800 x 600 dpi, 112 lm/h, 200 m2/h

2-Pass 800 x 600 dpi, 56 lm/h, 100 m2/h - Print width: Max. Print Width 1850 mm (72.8 in.)

- Material transport: Integrated Feed-In System and Unwinder for rolls with a diameter of up to 400 mm (15.7 in.)

- Dryer: Heated Printing Table and Hot Air Dryer for rapid drying

- Print heads: Durst QuadroS Print heads

- Print Mode: Binary (7 pl) and variable droplet size with 7/14/21 Picoliters

- Resolution: Standard 800 x 600 dpi

- Sublimation Paper: Optional: “Direct Print Kit” for printing on coated and uncoated polyester fabric with a polyester percentage of more than 50 per cent. Other fibre mixtures can be printed, with some restrictions

- Inks: Durst Dye Sublimation-Ink set, CMYK, Light Cyan, Light Magenta, Light Black or special colours

Latest sewing machine from Fucen

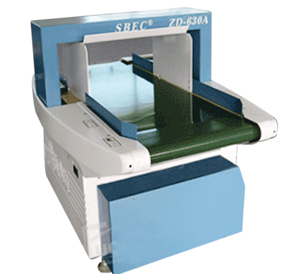

Fucen Sewing Machine Co. Ltd. is specialised in producing many types of industrial garment sewing machines. Fucen has been efficiently responding to the changing time and continuing to offer unique product and services to customer, make fast decisions and take quick action, with a challenging spirit and strong sense of responsibility. Some of the latest innovations by the company ares FC-818: Pneumatic single head snap fastening machine, FC-838: Pneumatic three head snap fastening machine, FCF-1000: Conveyer type fusing machine-belt width 900mm and ZD-630A-300: Magnetic induction needle detector automatic conveyer type.

ZD-630A-300 Magnetic induction needle detector automatic conveyer type

- Needle Detector Machine, Cycled, 9 pairs of sensor, excellent anti-disturbance performance

- Based on LED bar displayed control panel

- High accuracy detection locating technology, LED indication

- Level setup indication and real-time sensitivity display

- Optional conveying mode after alarm

- Optional automatically restart

- Reliability mechanical frame design, high stable during detection

- Needle Detector Machine, Designed for universal AC power supply, switch power supply

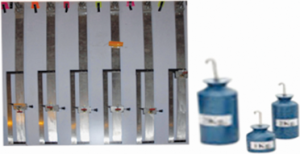

Stretch and Recovery Tester by Amith Garment Services

Amith Garment Services has recently launched Stretch and Recovery Tester wall mount type to find out recovery of textile material/narrow fabrics. The instrument is made as per the test standards D5278. This instrument is very useful for the fabric manufacturer/Yarn manufactures and garment exporters to find out stretch and recovery of their raw material.

Features:

- To measure stretch percentage and recovery properties of woven/knitted and Lycra fabrics/narrow elastic tapes

- Sturdy loading aluminum frame and screw tensioning device supplied

- Static load is applied for a specific time and released

- Percentage of elongation is read directly from the scale on the apparatus

- Unit can be mounted on the wall

- Supplied with 30N, 2.3kg, 1.8kg, 1.3kg rectangular loads with stainless steelhook and sample cutting templates.

New 2nd Generation GoTx Fabric Pre-Treatment System

For over a decade Impression Technology has designed, built and distributed numerous digital industrial print applications in the emerging markets of textile, graphics and label production. Its brands are global market leaders and respected within their communities because of our continual commitment to research and development.

Pigment.inc, a division of Impression Technology, Sydney, Australia, announces the launch of its completely redesigned second generation 1.9 (75-inches) and 2.6 meter (102-inches) pre-treatment units. After completely redesigning their first generation pre-treatment units, Impression has reduced the footprint size dramatically for use in areas where space is a premium. This is truly the first pretreat system for in-house use.

Incorporating a new non-bath single sided surface coating technology, the GoTx 1900PT/2600PT units use transfer rollers instead of fabric crushing to maintain the fabric surface. In fact, this unit is one of the first to not use either spray or soak coating methodology. Fabric handling is facilitated by an integrated defurling spreader roller for smoothing the fabric. Using adjustable guide rollers on the input and output side controls the coating consistency and prevents edge curling. The fabric is dried with a completely new TurboDryer dual exhaust system for extracting humidity and steam. The Turbo- Dryer system uses 30 per cent less electricity than other units and has standard electrical connections. The GoTx 1900PT/2600PT units are shipping immediately through the extensive worldwide international network of resellers, including Graphics One in the Americas. Pricing for the units is $33,500 for the 1.9 meter unit and $39,500 for the 2.6-mtr unit.

T-Shirt Printer Iris 2000 by Vee Kay Enterprises

Twenty five year old business group Vee Kay Enterprises has made a success story of every business it has been into. Vee Kay has carved a niche for itself as a total solutions provider for the digital textile & signage industry with superior infrastructure and a committed work force. As an organisation, over the last few years, the company has expanded its operations by opening branches in the all major cities of India. Given are the features of its latest T-Shirt Printer Iris 2000: • Printing technology: VSD Pizeo Inkjet Method • Print Head & Quantity: Industrial Heads 4 • Printing Size : 400mm*500mm 600mm*800mm • Ink System • Ink Type: Pigment • Ink Colour: CMYK and W • Ink Volume: 2000ml / colour • Printing Mode (4 colour): Mode – Printing speed: 6 pass, 36s; 8 pass, 48s • Printing Mode (2 colour +2white): 6 Pass, 36s; 8 Pass, 48s; 12 Pass, 72s • Fabric Standard: Fabric Size – 400mm*500mm 600mm*800mm; Fabric Type – Cotton, hemp, silk, nylon, polyester, wool and cashmere • Working Condition: Humidity – 45%-85% and Temperature – 10ºC-35º C • Windows System: Window XP, WIN7, WIN 8 • Display: Computer Display • Interface: 100MB (100MB network interface) • RIP Software: AJet RIP • Power: AC110/220V, 50HZ/60HZ • Noise: 60dB.

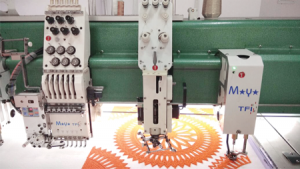

Multi–head Automatic Embroidery Machine by Tajima

In 1964, the TAJIMA group developed a multi-head embroidery machine. Since then, it has made expensive manually produced embroidery accessible and familiar to the people of the world, and added beauty to their lives. TFGN II – Series Multi–head Automatic Embroidery Machine is one of the revolutionary technology introduced by the company. It is a high-end model making the most use of Tajima’s technologies. Also, high-grade machine having extended functionality and superior performance.

The TFGN Series, Tajima’s flagship model, has just been renewed. Features:

- High Work Efficiency: The newly designed middle thread guide has halved the thread setting time for one needle compared with its conventional parts. You can set thread tension easily

- Value-added product making: Since needle sizes from #9 to # 18 can be used, the applicable thread variety from thin thread to thick thread has expanded dramatically. When the thick replacing parts kit attachable/ detachable by one-touch operation is used, thick thread embroidery can be done easily. Furthermore, when some refinements are added to the design data, more unique, higher value-added products can be produced

- Stable Stitching: In order to keep up stable quality, thread condition should be adjusted according to thread type, fabric and design. The tension and stroke of the thread take–up spring, which have been adjusted for each head, can now be adjusted for each needle bar. Since the adjustment can be made according to thread to thread type and stitching method, product quality can be further enhanced

Automatic Oval Screen Printing Press and Digital Printhead by M&R

Begun in 1985, M&R started out with three employees, doing maintenance and repair for screen printers who were dissatisfied with the service provided by the manufacturers of their screen printing presses and other screen printing equipment. Just one year later, M&R began manufacturing manual screen printing presses. Today, M&R produces a wide array of screen printing products and OEM screen printing parts at facilities in Roselle, Illinois, USA and in Wojnicz, Poland. M&R has distributors and support operations throughout the world. In India the company is represented by DCC group of companies. Given are its latest machineries.

Automatic Oval Screen Printing Press

Features:

- Available in six-station modules from 22 stations/6 colours to 64 stations/24 colours

- Maximum image areas are 42 x 70 cm (16.5″ x 27.5″) on small pallets and 55 x 70 cm (21.5″ x 27.5″) on large pallets

- Servo-driven indexer and electric printheads provide exceptional smoothness, consistency, and longevity

- Optional digital print station allows screen/digital hybrid printing

M&R’s aggressively-priced VictoryOne oval press is aimed at the international market. VictoryOne’s 22-station base module can be expanded in 6-station increments to create 28, 34, 40, 46, 52, 58, and 64-station configurations. All but the four stations at each end of the press can support printheads, which must be configured in opposing pairs. Otherwise, there are no restrictions on printhead placement, and any station can be left open. VictoryOne’s flexibility allows it to be tailored to almost any production requirement. It also allows VictoryOne to fit into spots no carousel press could.

VictoryOne’s maximum screen frame size is 68 x 99 cm (26.5″ x 38.9″). Maximum image area is 42 x 70 cm (16.5″ x 27.5″) on the small pallet and 55 x 70 cm (21.5″ x 27.5″) on the large pallet. Small pallets are 45 x 85 cm (17.7″ x 33.5″) and large pallets are 58 x 85 cm (22.8″ x 33.5″).

Each press comes with 500 frame-adaptor pins for static aluminum frames, a jig for drilling frames, and a screen frame registration system. Other features include servo-driven indexer and printheads, reversible rotation, front and rear off-contact adjustments, front and rear micro registration, calibrated tool-free front and rear stroke-length adjustments, quick-lock squeegee and floodbar mounting with toolfree angle adjustments, and a touch screen main control panel. Printheads are made of sturdy 11 x 13 cm (4.25″ x 5″) extruded aluminum with a servo belt-driven print carriage riding on enclosed linear bearings.

A soft-touch membrane control panel on each printhead provides access to print and index functions. A pneumatic squeegee pressure regulator delivers consistent print pressure. VictoryOne’s quick-lock head-latch mechanism activates a springassisted high lift, allowing operators to quickly raise the screen for cleaning or removal. An air-assisted rear frame support facilitates quick screen loading and unloading. A pin-type frame holder interface allows for true on-contact printing when needed, while individual front/rear off-contact and smooth micro-registration tools give operators full control of screen alignment and off-contact settings. VictoryOne also has standard flash-cure power distribution with on-press plugs. Also available are standalone Sechuan® quartz flash-cure units, which are designed specifically for the VictoryOne oval press.

VictoryOne® Digital Printhead

- Allows printers to use conventional inks for white underbase and special effects in combination with high-speed custom digital printing

- Fully integrated with M&R’s VictoryOne®

- Automatic Oval Screen Printing Press

- Maximum image area of

- 44.8 x 50.8 cm (18″ x 20″)

- Up to 400 prints per hour at A4 size

M&R’s new VictoryOne digital hybrid screen printing system brings the worlds of conventional screen printing and direct-to-garment digital printing together in a way that is efficient, flexible, and profitable. The VictoryOne digital hybrid screen printing system allows screen printers to use the custom, on-demand printing available through digital direct-to garment technology in combination with screenprinted effects like puff and glitter inks.

The VictoryOne digital hybrid system will bring a new level of versatility and profitability to conventional screen printing operations by allowing those operations to take on work that can’t be done by screen printing alone—and to do it at speeds unheard of on standalone DTG printers. The system is compatible with RIP software from Ergosoft, Wasatch®, Neostampa and Caldera, and is capable of printing on natural and synthetic fibres, including polyester, nylon and blends. With an automatic cleaning system and integrated humidifier, operation and maintenance are greatly simplified.

Cold Pigment Dyeing and Dry to dry Process Machines by Fabcare

Established in 1995, Fabcare Garments & Textile Machinery Private Limited is one of the manufacturers and suppliers of garments & textile machinery in India. Its range is made as per the set industry norms and guidelines, utilising the finest raw materials and modern machines. This ensures the product’s performance, service line, strength and capacity. The offered range is made up of the finest textile machines, washer extractor and washing machine, which are widely demanded. In addition to this, the offered range is priced at the most reasonable rate possible.

The company recently launched first of its kind Cold Pigment Dyeing Machine and Dry to dry Process Machine, which is fully automatic. The machines completely made of stainless steel with spray technology. The new machines allow a lot of savings to the users in terms of water by almost 90 per cent, less manpower usage and space requirements.

Sewfine Embroidery Machine from Dolphin Jingwei

Dolphin Jingwei Machines is associated with Hangzhou Jingwei Electronic Mechanical Mfg Co. Ltd as their Sole Pan India dealer for their entire range of machines. All products are supplied under TANG brand. Hangzhou Jingwei has been supplying machines in India since 2003 & is one of the oldest Chinese companies still dealing in India. Today, TANG brand is considered the best among Chinese machines for its high quality, low maintenance, superior stitch quality without compromising on production. All these reasons have resulted in faster recovery of the buyers’ investment. One of the company’s latest machines is GGS Sewfine Series Embroidery Machine. Given are its main Function Characteristics:

- The mechanical structure is excellent and reliable, Lay the perfect embroidery with maximum speed can reach 1000rpm

- Have the industry the most advanced production and assembly process

- The machine with new structure: Have the perfect structural design, uses the high strength steel and welding process maturity, guarantee the mechanical stability and the resistance to shock

- Super low noise mechanical design: Advanced; silencing transmission structure head design is excellent; This structure not only has greatly reduced noise, also has function of easily adjust thehigh presser foot, reduce the pressure foot, hit the cloth or needle plate which cause embroidery destroyed, reel of the yarn from the material and leave presser foot print on material, Especially for the think material embroidery and three-dimensional (3D) embroidery has most obvious effect.

- Thread hold device: Independent electromagnetic valve control, when trimming thread, colour change, replenishing embroidering, the thread hold device has function can effectively improve or prevent the thread out of needle hole or bobbin thread dis-connect with thread for other heads.

- New type structure for colour change system: Use precise liner design, when working is light, high precision, dustproof ability, long service life. Advanced bearing and linear motion technology provides more accurate positioning support

- Head needle bar jump structure: Advanced micro pulse motor drive technology. This structure is convenient to install, No noise design, truly realize the optimum operating at high speed, precise positioning

- A new type middle thread guide: Combined with the original foundation improved the new structure thread guide device greatly improve tight, the thread during embroidery, Even when running at high speed can also lays a solid foundation for improving the quality of the products

- A new type tension base, selected high – Precision thread breakage technology, whether it is bobbin thread or upper thread breakage the computer

system can immediately detect and stop machine. Computer system parameters can be adjusted according to the sensitivity of different kinds of embroidery. Compared with the old version, greatly improved thread guide pressure. Make thread tension and stitch more stable - A new type hook thread device: Gear reducer motor assembly designs this structure it’s convenient to installation and adjustment. At the same time, greatly improves the hook thread device of precision and mechanical stability.

- A new trimming system: Advanced pulse motor drive design, trimming action compliance, start at accurate positioning. Large torque, low noise, Compared with the traditional gear style. Synchronous action when the disadvantage of reducing spindle power finally been solved properly

- A new type pantograph structure: High strength, light, high precision, Novel aluminum alloy structure, is the basic guarantee of high quality high speed embroidery

- Pantograph drive system: Use nowadays one of the highest precision AC servo motor drive, fully reflects the advanced technology of motor, it is the best choice to achieve high and low speed, high precision operation

- The main transmission adopts the synchronous belt in Germany and Italy production, Gear precision, polyurethane material, make it with excellent performance stability. Small deformation, long service life, And greatly saves the cost repair and daily tedious

- Accurate frame drive slide rail group: The advanced bearing and linear motion technology High rigid material, High-precision processing technology, High sealing performance dust gauge block group design, Can easily face strict production requirements.

New range of highly specialised embroidery technologies from Aura Technologies

Aura Technologies is the professional leader in highly efficient, long life, cost effective solutions for value additions in the garment and home textiles segment for past 12 years in the industry having deep insight into the industry and has many exporters using sampling setups and then graduating to full-fledged production setups with the help and support. According to the company, in today’s fast paced world of textiles, product development is of utmost and prime importance, a solid design development team who is updated on latest technologies and tools available is an added advantage, and speed of product development is the main factor today which can change the outcome of today’s businesses. Some of company’s recently introduced technologies are:

- LAMS-MB SERIES a premium level high speed machine with special patented Multi Depth Insertion Boring. The machine has technology for Schiffli like boring quality and flexibility of multi head working.

- Another offering is the LEO-III series – A premium level real high speed multihead machine with latest technological features with new attachments for adding wings to creative embroideries.

- The HSCX-II series is the only real premium level high speed chenille mixed head embroidery machines with many new developments to ensure stable working and quality.

- The RAFTAAR series of machines is designed for robustness and long life.

- The LY-CX series chenille has a mixed head embroidery machines with many multi functions in one machine for wide range of embroidery applications.

- Another latest innovation by the company is Aura MS series: Mini Schiffli range (Repeats of 8×4, 12×4, 16×4, 24×4, 32×4). Along with the above, Aura Technologies specialises and have highest number of installations for laser and glass beads attachments for high quality value addition, the company says.

High speed embroidery machines by Unix

Established in 2002, Unix Stitch Machines Pvt. Ltd. is one of the most innovative and creative companies emerging in computer embroidery industry. Within a short span of time the company has positioned itself as a pioneer technology supplier in the embroidery industry with a distinctive identity. Given are some of latest innovations:

High Speed Laser Embroidery Machine

Equipped with laser system on the computer embroidery machine, which perfectly combines the technology of computer embroidery with laser cutting and the patterns fully realise the digital control. It saves abundant costs of plate making and knife mold production, eliminates the time cost and quality limitations of the traditional manual cutting, effectively reduces the production cost and improves the efficiency.

Suitable on various fabrics for special embroidery, applique, engraving, edgecutting, punching and stratified cutting, which can not only enrich the embroidery technology, but also improve the product quality and value addition. It makes the embroidery appeal more prominent with higher quality and stronger aesthetic feel. It creates a new era in the embroidery process and provides a new solution to garment, home textile and fabrics decoration industry.

High Speed Embroidery Machine 18 heads, 9 colour, Max. speed 1200SPM, Emb. Area in 400x800x1300

Unix high speed embroidery machine productivity is achieved by ultra -precise control 1200 RPM in standard embroidery, which can meet various consumer demands for creation of high value added embroidery work. Sequin can be programmed into the design data or loaded manually via the control panel.

Features:

- Indecent double can driving system for driving and pressure foot lifting, which guarantee the high speed machine to running at very high speed with perfect embroidering and quite working conditions

- Latest semi auto oil system with separate oiling routes for upper head and lower rotary hooks system greatly extend the machine life

- Latest and advanced Germany Technology for X.Y 12CM wide driver system, which can ensure 1200RPM running speed and perfect stitch at high speed as well as long life span

- RHP high and Jumbo bearing for guide rail trolley

- German brand Fulong belt for perfect stitches at high speed running conditions inside with glasses fibre instead of steel

- X,Y servo motor with 8cm wide belt pulley and belt which guarantee the high accuracy sewing work as well as life span

- Motorized jumper to support high speed running, and high speed jump stitch

- Latest Barudan standard quality tension base, with bearing type tension wheel ensure the thread feeding stability under high speed running as well as head life

- Extra enhanced heavy chassis for advanced bridge style machine body with H Beam support to resist vibration during high speed embroidering

- Enhanced pantograph aluminum material and SWF style pantograph side support

- New table mica, aluminum operation bar, stainless steel cover etc. for good machine finishing as well as quality

- Original Japan Hirose rotary hook sets, original Japan encoder, and original NSK key bearings for machine moving and transmission parts

- The more advanced high speed control system is designed and made with more accurate stitching and pantograph motion programming

Rotary Heat Press for sublimation from Eastsign

Eastsign is a leading manufacturer/supplier of offering a comprehensive lineup of digital materials and equipment for all ways of printings. The head office is located in Hong Kong and with the production based in Mainland China which established in 2002. Its customers benefit from high quality products, professional consolidation and sourcing in all areas of business. Eastsign play a leading role in signage industry as vital source in digital textile printing, large format printing for billboards and screen printing.

Rotary Heat Press MOT-M – (MOT-M Series) Middle Class Multi – Functional (Piece-by-piece or Roll-to-roll)

- Garments

- Mouse pad, carpet

- Flag, tent, blanket, curtain

- Polyester Fabric in Rolls or piece

Features:

- Rotary Heat Press for Roll-to roll or piece – by – piece

- Three feeding rolls and two take-up rolls

- Flag, tent, blanket, curtain

- Duplex teflon oil drum

- Air expanding shaft included

- Hand crank blanket tension

- Blanket release system

- Max width: 3.2m or 126’’

Rotary Heat Press SOT (SOT – 1220) SOT Series

- Graments

- Mouse pad, carpet

- Flag, tent, blanket, curtain

- Polyester Fabric in Rolls or piece

Features:

- Oil Drum, 200mm or 7.9’’

- 3 pairs of feeding and Take-up Rolls

- Manual Blanket Release system by Hand Crank

- Working Width:1.22m/1.37m or 48’’/54’’

- Rotary Heat Press for making dye sublimation

- Heat Transfer Sample

- Aligning Blanket Automatically (Optional)

Mini schiffli embroidery machine by Baba Textile Machinery

Established in 2005, Baba Textile Machinery (India) Pvt. Ltd., is a young and dynamic technology solution provider company from New Delhi. It is an importer and supplier of garment and textile machinery in Northern and Eastern India, having sales and service offices in Kolkata, Varanasi and Jaipur. The company is committed to satisfying customers by supplying best quality technologies at competitive price. Its product range include computer embroidery machine, rapier loom and laser cutting machine. In a short span of time the company has sold more than 5000 machines, which itself reflects the quality of the machine and service provided by the company. One of the latest innovations by the company is Mini Schiffli embroidery machine (90 heads, 4 needles).

Shape Pearl Fix and Rhinestone Transfer Paper Machines by FZY

Zhejiang FZY Machinery Co., Ltd. is one of professional ultrasonic rhinestone hotfix machine manufacturer from China. The company is highly appraised by its customers for its low energy consumption, high efficiency, easy operation, high stability and high performance-price ratio. Its products are sold all over the domestic market, as well as foreign countries such as Russia, India, Morocco, Bangladesh, Egypt, Brazil, Dubai, etc. In India, the company is represented by Peayush Machineries Private Limited. Given are two of its latest machines:

Shape Pearl Fix Machine (FZY-DZY)

- Speed over 300 pearls per min. Only 50 per cent air content is consumed compared with same product manufactured by averages so as to save electricity by 40 per cent

- Originally imported cylinder and chips ensure high quality

- Full digital control and LCD display. Multiple languages are supported such as Chinese, English, Russian, Arabic etc.

- Can running type different shape pearls and half pearl, also can running round pearls

Semi-Auto Rhinestone Transfer Paper Machine (FZY-SZ1)

- High efficiency: Machine with high speed, reduce the worker working time, can finish multi-colour in short time with the high efficiency

- Universality: The stone template , transfer paper same as the traditional manual working

- Low energy consumption: 24 hour working less than 2 KWH

Laser engraving, cutting and marking machines by Peayush Machineries

Located in the city of New Delhi, Peayush Machineries Pvt. Ltd. is specialised in computer embroidery machines and spare parts as well. Since the establishment in 2006, the company has developed into a hi-tech enterprise. Nowadays its products are sold not only domestic market but also widely accepted by foreign clients of 20 nations from Europe, South America, Middle East and etc. Given are some of the latest offerings by the company under DAYU brand:

DY Non-metal Material Laser Engraving & Cutting Machine Double Head Series

Product features: Two laser heads working at same time double enhances the working efficiency, adopted imported high precision spare parts, stable and reliable DSP control system, simple and convenient man-machine interface, stable motion drive system with superior performance. High precision moving rails, all these make machine the features of high efficiency, energy conservation, stability and convenience during working.

Applicable industry: Garment, leather, cloth toys, embroidery patch cutting, module, arts and crafts, advertising, decoration, packing print and so on.

Applicable materials: Cloth, wool, leather, paper, plastic, rubber, PVC plate, wood, plexiglass, epoxy resin, crystal, tile and so on.

DY150Q-3D/DY275W Co2 Dynamic Auto Focus Laser Marking Machine

Product features: Co2 Dynamic auto focus laser marking machine is a new machine system for large area marking, it ends up the history of laser join for large area marking. Its application greatly increases the product quality and working efficiency.

- Adopt imported RF Laser Device of high laser power, with the characteristics of high power, fine laser, high frequency, little power lose, high precision, long life span

- Sealed optical system, which prevents the dust from the laser device

- Imported dynamic optical system, ensure the high scanning and marking speed

- Water circulated cooled dynamic auto focus system solves the problem of heat radiation of vibration lens, motors and drives, ensuring the working precision and stability under long time work condition

- Independent water cooled extending lens, together with other imported lens. Ensure the good working stability and the life span extension

- Motorized up & down laser head, which automatically adjust the focus distance conveniently

- Up & down exhauster system, which gives sufficient material suction & smoke driven

- Working area is optional according to marking requirement

- Professional image edit software which is compatible with various format. Powerful controlling configuration all these makes high speed and stable working

- Room sealed machine body design makes safe operation

Applicable industry: Shoes, Garments, Bags & Suitcase, Art & Craft advertisement, electronic, printing mould and so on.

Applicable material: Genuine leather, synthetic leather, cloth, wood, & bamboo, Paper, rubber, plastic resin, acrylic and so on.