Incorporated in 2001, Super Sonic Impex is one of the largest import & export trading company situated in Surat, Gujarat. The company is dedicated to serve high quality and cost-effective product to customers always. Its product includes textile related machinery and machinery parts, industrial electronics products, automation product etc.

The company is one of the leading wholesalers for Automatic Bobbin Winder Machine backed by close business association with leading manufacturers. These machines are designed as per the superior quality standards using the best grade raw material and latest techniques. One of the innovative additions by the company to its offerings is Ready Bobbin.

Ready Bobbin is one of the most leading embroidery companies since 30 years. One roof to provide all kinds of embroidery products with more than 40 different items. Ready Bobbin is first only company with embroidery supplies less than one roof.

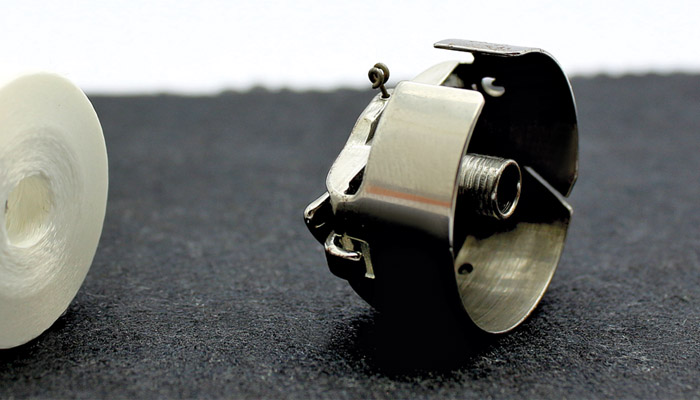

What is Ready Bobbin?

It is a professionally manufactured-Bobbin which is made to be used as an underthread, to replace the old handmade Bobbin in Both Garment & Embroidery Machines for the purpose of increasing productivity & saving costs.

“Saving Time”

- The Bobbin has 3-4 times more length with fine thread so it will run for much longer time uninterrupted

- The Bobbin has low changing time, which minimized the machine downtime

- Less cutting thread due to its knotless characteristic and exact tension along the bobbin thread.

- The entire bobbin would have the same length which save the effort to stop the machine that replaces only one bobbin

- No time wastage for winding process & maintaining winding machines

Increase productivity

- Much more longer thread to work with in each bobbin

- 100 per cent knotless fine thread to give distinguished output

- Prefect bobbin spinning due to professional winding to be fully compatible with upper-thread running

- Total ability to match any count & colour of upper thread in case customer requires such preferences

- Increases stocking space after getting rid of winding machines+Spun polyestercones which require vast area

Saving cost

- Saving the cost of maintain & repair winding machines

- Thread wastage is up to 10 per cent handmade bobbin plus 25 per cent thread wastage during winding process

- Saving staff salaries

- Saving providing Electricity for winding machine

- Saving your bobbin case from damage due to unfit shape of handmade bobbin

- Saving needles from repeated breakage accidents due to unwanted contact with metal sides of bobbin

Benefits f using ready bobbin

- For the customer: Softer, finer and higher quality embroidery and less skin irritation from the back of the embroidery

- For the Factory: Extends the life of embroidery needles since the needles will not have to come in contact with the metal sides of the old type selfwound bobbin

- Metal Bobbins: Save the cost of having to buy any metal bobbin

- Winding Machine: Save the cost of having to buy, se and maintain a winding Machine

- Labour: Save the cost of having to hire winding labour

- Electricity: No extra electricity bill for winding

- Storage: Optimizes stock space and stock control

- Bobbin case: Reduces the need for frequent cleaning of the bobbin case due to hairless bobbin filament. Reduces damage to the bobbin case as a result of professional winding

- Efficiency: Full length of the yarn can be utilized, reducing the unseen loss of self-wound bobbins

- Effectiveness: Reduces frequent stoppage of machinery due to consistently more than double the length of yarn compared to self-wound bobbin

- Consistency: Uniform yarn tension throughout the bobbin, resulting in higher quality and consistency of embroidery