Through an innovative, patent-pending technology, Smart Foam minimizes natural resource consumption, making sustainable garment production easy and accessible.

Innovative

Innovative

Smart Foam is a patent-pending technology, a result of collaboration from three leading companies across the garment finishing market.

To treat garments in any kind of washing machine, Smart Foam introduces foam as a new carrier of chemicals. It can be used to create everything from traditional finishes to unique fashion concepts and styles.

Sustainable

Sustainable

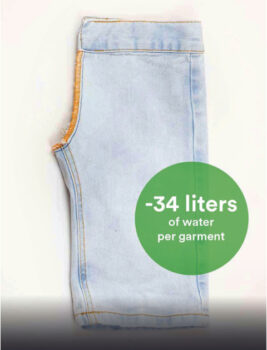

Smart Foam greatly reduces the consumption of water and energy.

Compared to traditional washing processes, the application of chemicals through Smart Foam allows savings of up to 80% of water.

All the treatments are performed at room temperature, therefore reducing the minimum energy required.

Smart Foam has been designed to make the technological investment accessible to any industrial laundry. This helps suppliers of any segment achieve their sustainability goals, to better serve the fast-moving fashion industry.

When combined with Garmon certified chemicals, Smart Foam can be used to perform treatments fully compliant with greenofchange® requirements.

Easy

Easy

Smart Foam has been designed to be the easiest and most affordable system to save water in garment finishing, providing solutions for any industrial laundry.

Compared to nebulization systems, Smart Foam loads chemicals in the washing machine up to 3 times faster, and doesn’t require sealed equipment, allowing technicians to interrupt finishing treatments and check garments with safety and ease.

Any type of washing machine – from the traditional to the advanced – can be utilized with the Smart Foam equipment and process.

Smart Foam is the result of:

1. Garmon’s tested and selected range of chemicals

2. Garmon’s special foaming agents

3. Foam generating equipment recommended by Garmon

The combination of these factors is what creates the patent-pending smart foam technology

#madewithsmartfoam

#madewithsmartfoam

When developing the patent-pending technology of Smart Foam, we focused on how every customer, and every laundry, would use the machine day-to-day. As a result, we developed a technology that reflects both the technical and creative sides of the garment finishing process.

Compatible with more than 30 different types of chemicals, Smart Foam creates garments from the basic to the avant-garde: enzymatic washes, bleaching, resins and 3D effects, softening and even dyeing.

Bleaching with Smart Foam: any shade you like

Bleaching with Smart Foam: any shade you like

Smart Foam allows saving water in every bleaching treatment performed with sodium hypochlorite or with Garmon’s sustainable bleaching agents like avol evanix. Through the right combination of bleaching agents and treatment times, you can achieve any blue shade of denim you want, from the darker tones to the fully bleached ones.

Compared to a traditional process, a bleaching performed with Smart Foam allows saving up to 41 liters of water on a single garment, which means a saving of 81%. And yes, compared to a nebulization system you can interrupt the treatment to easily check garments’ bleaching level.

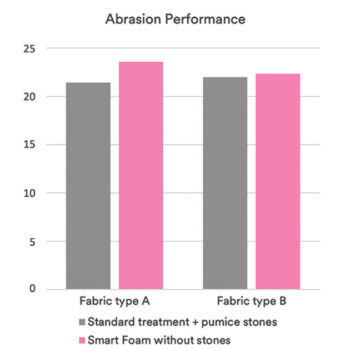

Stone washing with Smart Foam: increased abrasion

Stone washing with Smart Foam: increased abrasion

Our tests prove that, with the reduced liquor ratio, some treatments like enzymatic washes with Smart Foam produce a better abrasion compared to the standard treatments.

This means that with a smart foam enzymatic washing with NO pumice, you can match the level of abrasion of a standard mild treatments requiring pumice stones.