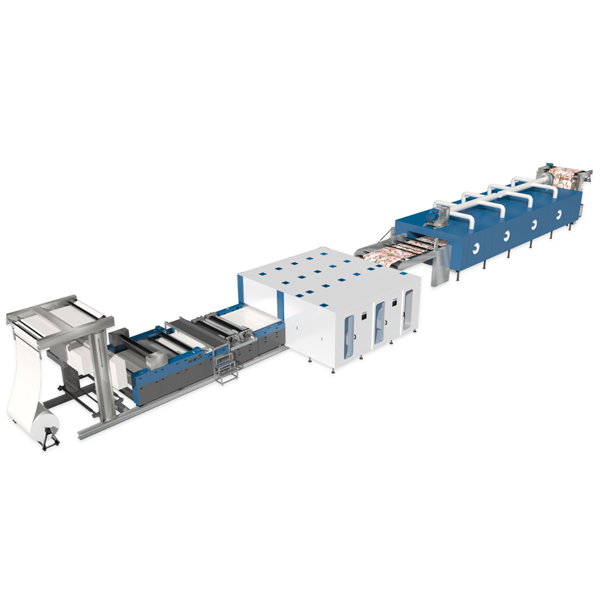

Atexco India unveils Vega One – Revolutionary Single Pass Digital Textile Printing Machine

Atexco India, a leader in industrial digital printing solutions, proudly announces the launch of its latest innovation – Vega One, a next-generation Single Pass Digital Textile Printing Machine set to redefine speed, quality, and efficiency in textile manufacturing.

Atexco India, a leader in industrial digital printing solutions, proudly announces the launch of its latest innovation – Vega One, a next-generation Single Pass Digital Textile Printing Machine set to redefine speed, quality, and efficiency in textile manufacturing.

Specifically engineered for large-scale textile mills and high-output exporters, the Vega One is designed to meet the growing demand for faster production timelines, consistent quality, and sustainable operations.

Key Features of Vega One:

• Single Pass Technology – Enables ultra-fast printing in a single go, ideal for bulk production and time-sensitive orders

• Exceptional Print Quality – Delivers brilliant colors, crisp detailing, and stable output—meter after meter

• Industrial-Grade Performance – Built for continuous, high-volume operation with minimal downtime

• Smart & Sustainable – Features energy-efficient systems, eco-friendly inks, and user-friendly controls

With Vega One, Atexco India is bringing world-class single pass technology to the heart of Indian textile manufacturing. This machine is not just about speed—it’s about delivering exceptional results at scale, while meeting the sustainability goals of today’s forward thinking mills and exporters.

From fashion fabrics to home textiles, Vega One empowers manufacturers to boost production capacity, diversify design offerings, and improve profitability. Already trusted by some of the country’s leading textile producers, Vega One is poised to become the go-to solution for future-ready digital printing.

Why textile precision matters in swimwear

As temperatures rise, certain products step into the spotlight that usually spend the rest of the year on the sidelines – swimwear among them. To ensure swimwear not only looks good in summer but also performs reliably, textile precision is essential. Behind every bikini and swimsuit lies a sophisticated production process, where even the smallest errors can have major consequences.

Elastic, Shape-Retaining, and Chlorine-Resistant

Swimwear must meet a wide range of requirements: high elasticity, recovery, UV resistance, and durability against chlorine are basic standards. These properties are made possible by technical knits based on polyamide or polyester combined with elastane. Typically produced in tricot knit, these fabrics are stretchable in both directions – ideal for a close fit and full freedom of movement in water.

But to achieve a perfect final product, the material composition alone is not enough. Processing in the earlier production stages – especially fabric forming and finishing – plays a crucial role. Elastic materials are particularly prone to distortion. If this isn’t corrected before further processing, the result can be skewed patterns, uneven seams, or misshaped silhouettes.

Distortion-Free Fabric as a Quality Feature

This is where Mahlo’sOrthopac RXVMC comes into play. The latest addition to the weft straightener family is designed specifically for elastic materials with high distortion dynamics – a common feature in swimwear.

Equipped with two independently driven straightening modules – one at the fabric’s entry and one at the exit – the system enables particularly fine and rapid corrections. It reliably compensates for skew and bow distortions before the fabric continues to the next production steps. The result is not only improved fit but also stable printing and finishing outcomes.

Technology for Perfect Finishing

Only when the fabric is precisely aligned can finishes like chlorine resistance, UV protection, or the popular lotus effect be applied evenly. Accurate dosage is critical: too little finish limits functionality; too much wastes raw materials and drives up costs.

To ensure precise control of these processes, Mahlo has developed the Qualiscan QMS – a modular online measurement system equipped with applicationspecific sensors for thickness, basis weight, or moisture. It continuously monitors the finishing process, ensuring consistently high product quality.

Conclusion: Precision Saves Your Summer

Swimwear may look light and playful at first glance – but in reality, it’s backed by highly sensitive textile technology. Only when all stages – from fabric alignment to straightening and finishing – are perfectly coordinated, can a product emerge that passes the ultimate summer test. With technologies like Orthopac RXVMC and Qualiscan QMS, Mahlo provides the tools to manufacture summer textiles that are not only stylish but also functional and cost-efficient.

SINGER India introduces SE1201F-58 the latest Single Head 12 Needle Embroidery Machine

Introducing the SINGER SE1201F-58: Precision Embroidery Redefined

Introducing the SINGER SE1201F-58: Precision Embroidery Redefined

Step into a new era of embroidery excellence with the SINGER SE1201F-58, a state-of-the-art industrial embroidery machine engineered for professionals. Whether you’re operating a boutique, scaling up production, or delivering intricate custom designs, this machine delivers flawless performance and unmatched reliability. The machine comes with some important features like:

A Sleek 10” Full-Color Touchscreen Panel

• Intuitive Control & Navigation: The vibrant 10” LCD touchscreen offers a user-friendly interface, enabling you to easily access embroidery files, monitor realtime stitch progress, and make on-the-fly adjustments

• Preview before You Stitch: With on-screen previews, you can visualize your design at actual scale before stitching begins-reducing costly mistakes and material waste

Industry-Leading Embroidery Area: 500 × 800 mm

• Oversized Design Space: The generous 500×800 mm embroidery frame is one of the largest in its class

• Seamless Flat Embroidery: Designed for fabric fed perfectly flat, this system eliminates distortion

Built for Speed: 1,200?RPM Maximum Rate

• Rapid Stitching Capability: At up to 1,200 stitches per minute, the SE1201F-58 lets you complete large-scale designs in a fraction of the time

• High Productivity Output: Maximize batch efficiency with reduced stitch-by-stitch delays

Global Voltage Flexibility: 80 V–260 V Support

• Unmatched Versatility: Built to accommodate voltage from 80 V to 260 V, this machine is ready For installation anywhere

• Travel-Friendly Setup: Whether relocating workshops or deploying units across multiple sites, worry less about electrical compatibility

Robust Industrial Design

• Heavy-Duty Durability: Built on a reinforced steel chassis

• Professional Motor & Drive System: Equipped with a high-torque motor that powers through thick layers

Seamless Workflow & Premium Output

• Effortless Project Handling: Real-time thread-color change notifications and swift thread break Detection

• Consistent Stitches: Ensures consistent thread tension and impeccable stitch quality

Who Is This For?

• Boutique Designers & Fashion Labels

• Uniform & Corporate Branding Providers

• Embroidery Entrepreneurs

• Institutes & Training Centers

Set-Up & After-Sales Support

• Out-of-the-Box Ready: Supplied with flat hoop and tools

• SINGER India Service Network: Nationwide supportcoverage

• Training & Resources: Access to online videos, user manuals, and guides

Take Control of Your Creations

By choosing the SE1201F-58, you’re investing in:

• Reliability

• Efficiency

• Professionalism

Final Thoughts

If you’re serious about embroidery craftsmanship, the SINGER SE1201F-58 is your powerhouse partner.

Ready to Stitch with Precision?

Transform your design ambitions into reality. Visit SINGER India’s official store to explore availability

and pricing.

Sources & Specifications

• Product page: https://shop.SINGERindia.com/ product/se1201f-58/

• Key specs: 10” touchscreen, 500 ×800 mm area, flat embroidery, 1,200 RPM, 80 V–260 V power

GrozBeckert DBxK5 LGR Needle Enhanced thread protection in 3D embroidery

3D embroidery is a special type of embroidery that uses a foam material – also referred to as “puff foam” – to create a three-dimensional effect. During the embroidery process, the needle enters deeply into the foam, putting significant strain on the embroidery thread. The new Groz-Beckert DBxK5 LGR needle was specifically developed for 3D embroidery. It provides optimal protection for the embroidery thread and helps prevent thread breakage and skipped stitches.

3D embroidery is a special type of embroidery that uses a foam material – also referred to as “puff foam” – to create a three-dimensional effect. During the embroidery process, the needle enters deeply into the foam, putting significant strain on the embroidery thread. The new Groz-Beckert DBxK5 LGR needle was specifically developed for 3D embroidery. It provides optimal protection for the embroidery thread and helps prevent thread breakage and skipped stitches.

What is 3D embroidery?

In standard embroidery (also referred to as flat or 2D embroidery), the design is stitched directly onto the surface of the fabric, resulting in a flat finish. In contrast, 3D embroidery creates raised, three-dimensional designs. To achieve this effect, a foam material is placed on the surface of the fabric and stitched over with thread. The motif sits on top of the foam, creating the characteristic 3D appearance. At the end of the embroidery process, the excess foam is removed.

The challenge of 3D embroidery

The main challenge in 3D embroidery lies in the thickness of the foam that the needle must penetrate to form a stitch. With the very thick foams used for 3D embroidery, the needle may plunge into the foam all the way to the shank, causing the embroidery thread to become trapped between the needle and the foam. This can lead to skipped stitches and thread breakage.

The solution: The DBxK5 LGR needle

The DBxK5 LGR needle was specifically developed for 3D embroidery. It features a long thread groove that extends into the shank. When the needle enters the foam all the way to the shank, the extended groove provides space for the thread, ensuring improved protection. This prevents the thread from becoming trapped, even when thick foam is used, and significantly reduces the risk of thread breakage and skipped stitches. The DBxK5 LGR needle therefore ensures a reliable process with a highquality 3D embroidery result.

The advantages at a glance:

• Less thread breakage

• Stable embroidery process – even with thick foam

• Flawless high-quality 3D embroidery results

• Developed for industrial requirements

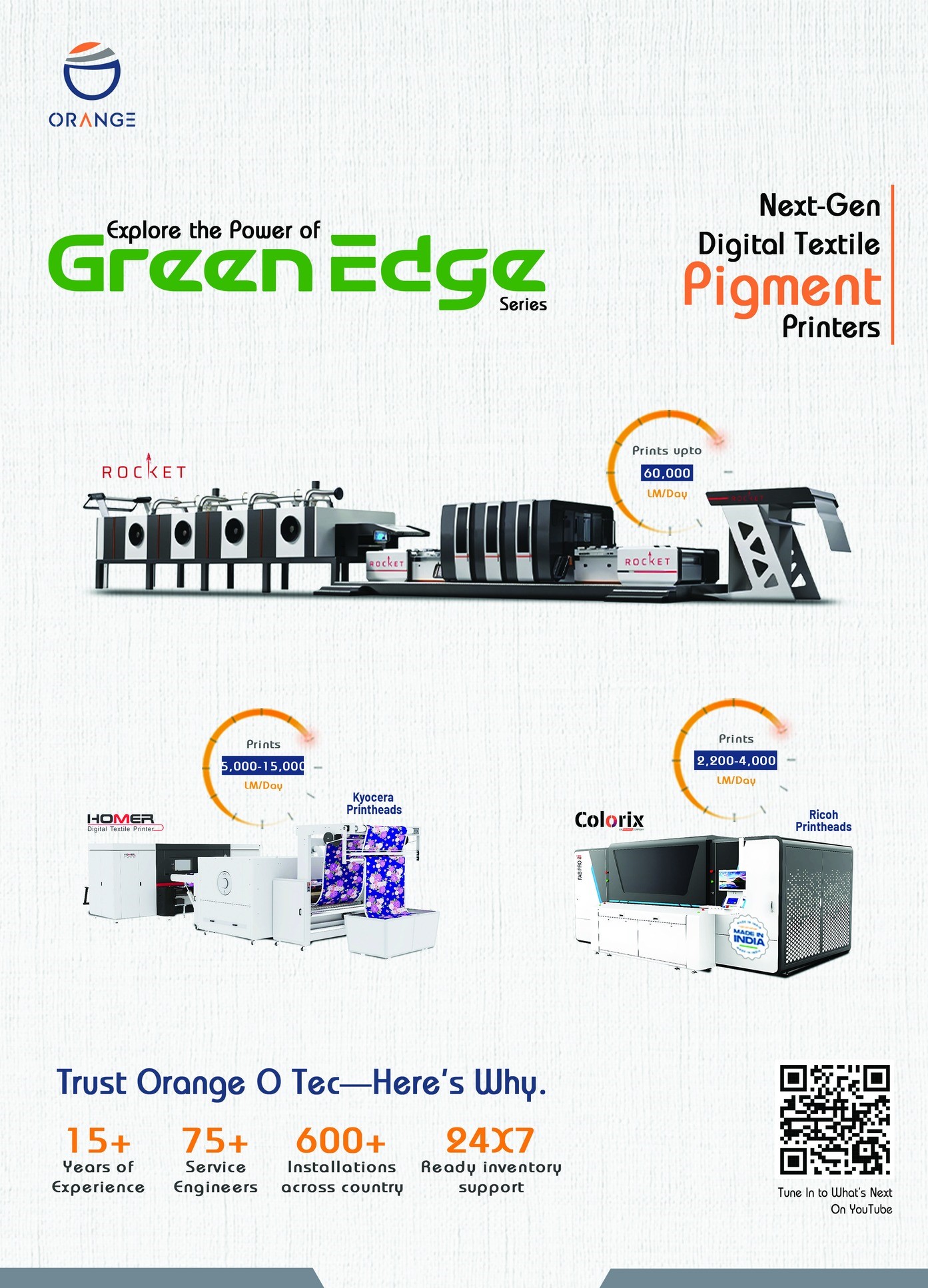

Introducing a Greener Tomorrow the Green Edge Series by Orange O Tec

In today’s rapidly evolving textile manufacturing industry, sustainability is no longer optional – it’s a necessity. As environmental regulations tighten and global brands demand greener supply chains, the spotlight has turned to eco-conscious innovations. At the forefront of this green revolution in India is Orange O Tec, a trailblazer in digital textile printing, with its groundbreaking Green Edge Series – a line of advanced pigment-based digital printers designed to align industrial output with environmental responsibility.

In today’s rapidly evolving textile manufacturing industry, sustainability is no longer optional – it’s a necessity. As environmental regulations tighten and global brands demand greener supply chains, the spotlight has turned to eco-conscious innovations. At the forefront of this green revolution in India is Orange O Tec, a trailblazer in digital textile printing, with its groundbreaking Green Edge Series – a line of advanced pigment-based digital printers designed to align industrial output with environmental responsibility.

Pioneering Sustainable Innovation from India’s Textile Hub

Headquartered in Surat, Gujarat, the heart of India’s textile belt, Orange O Tec Pvt. Ltd. was founded in 2011 with a vision to modernize the printing landscape. Over the past decade, the company has installed over 600 machines across India, achieving a turnover of Rs. 250+ crores, solidifying its role as a trusted leader in textile printing technology.

The Green Edge Series is Orange O Tec’s flagship sustainable innovation. Designed

with an eco-first philosophy, it combines waterless printing, reduced chemical usage, and high-speed output, setting new standards for efficiency and environmental compliance in textile manufacturing.

What Makes the Green Edge Series Unique?

At its core, the Green Edge Series is a direct-to-fabric pigment printing solution. Unlike traditional methods that require multiple water- and chemical-intensive steps—such as steaming, washing, and post-treatment – Green Edge printers use a single-step printing process. This not only shortens production timelines but significantly reduces the ecological footprint.

Compatible Fabrics and Applications:

• Fabrics: Cotton, polyester, blends, and synthetic textiles

• End Products: Fashion apparel, home furnishings, promotional fabrics, t-shirts, tote bags, and more

The technology is available across several printer models, including:

• FabPro 1i & 2i (Made in India)

• Homer K24, K32, K64

• Rocket (for high-volume industrial use)

These machines deliver print speeds ranging from 2,200 to 60,000 linear meters per day, offering tailored solutions for small businesses and large-scale exporters alike.

Pigment Ink: Clean Chemistry for Better Printing

Central to the Green Edge Series’ eco-innovation is its proprietary pigment ink technology. Developed to overcome the challenges of conventional dye-based systems, these water-based inks are:

• APEO-Free (The product does not contain any alkylphenolethoxylates.) and non-toxic

• Made from nanoscale pigment particles for high resolution

• Durable across washing, rubbing, dry cleaning, and perspiration

By forming a thin, flexible film on the fabric – cured at just 160°C – these inks eliminate the need for post-treatment, making the process more efficient and eco-friendlier.

Environmental Impact: Why Pigment Printing Leads the Way

Textile dyeing and printing are among the most polluting industrial processes. Traditional techniques consume vast amounts of water and energy while discharging harmful chemicals. The Green Edge Series directly addresses these issues:

Sustainability Highlights:

• 90–95% Water Savings: No steaming or washing needed

• Lower Energy Use: Energy-intensive machinery is bypassed

• Reduced Chemical Discharge: Minimal chemical use and safer waste

• Lower Emissions: Up to 70% fewer greenhouse gases during curing

These advantages make pigment printing not just a smart environmental choice, but also a long-term viable solution for manufacturers facing increasing green regulations and buyer expectations.

The Market Opportunity: Pigment Printing on the Rise

The global digital textile printing industry has seen significant growth, driven largely by sustainability concerns and technological advancement.

Key Market Trends:

• Market Size (2023): $3.2 Billion

• Pigment Ink Market Share: ~57% of direct-to-fabric segment

• Expected CAGR (2024–2032): 6.5%

• Forecasted Market Size (2032): $5.8 Billion

• Technological Shifts: Growth in AI-based monitoring, automation, and modular upgrades

With pigment ink poised to dominate over 65% of the market by 2030, Orange O Tec’s Green Edge Series is strategically positioned for future growth.

India’s Growing Role in the Global Sustainable Printing Ecosystem

Thanks to robust manufacturing capabilities and supportive government policies -such as the PLI Scheme for Textiles, Make in India, and ZLD (Zero Liquid Discharge) mandates – India is quickly becoming a global hub for sustainable textile printing.

Orange O Tec plays a central role in this transformation:

• 600+ Installations in key textile centres: Surat, Tirupur, Ludhiana, Noida

• Monthly Output: Over 3.5 crore linear meters

• In-house R&D in Surat for continuous innovation and machine upgrades

Whether you’re a boutique operation or a large-scale exporter, Orange O Tec offers

machines tailored to your needs:

Why Brands Choose Orange O Tec

In a competitive market, Orange O Tec stands out for its:

• Made in India Manufacturing

• 15+ Years of Expertise in textile printing

• PAN India Service Network with 75+ professionals

• Scalable Solutions for growing businesses

Green Edge: A Promise for a Greener Textile Future

As consumer expectations evolve and environmental regulations intensify, textile manufacturers must act decisively. Orange O Tec’s Green Edge Series delivers not only cutting-edge printing technology but also a transformative approach to sustainability.

For businesses seeking to future-proof operations while making a positive environmental impact, Green Edge isn’t just a printer – it’s a promise for a cleaner, greener future in textiles

Inside Kornit’s Apollo The industry’s mass production powerhouse

For many apparel producers, direct-to-garment printing is no longer just a niche technology – it’s a growing necessity. Moran Levy, Kornit’s Digital’s Director of Business Segments and EfiYohanani, Kornit Digital’s Product & Program Manager weigh in on what’s leading the next generation of DTG printing and how the Apollo is changing the game – one printed piece at a time.

As the digital printing industry moves toward faster, more agile production models, traditional analog methods can feel increasingly rigid. In the world of direct-to-garment (DTG) printing, the demand for speed, scalability, and sustainability has never been greater. With the apparel industry’s shift toward on-demand, just-in-time (JIT) production, Kornit Digital’s Apollo technology is the game-changing solution. The Apollo offers a bridge between the speed of analog and the flexibility of digital, purpose-built for high-volume operations. Developed over several years with input from some of the world’s busiest print floors and launched in 2023 after years of rigorous beta testing, the Apollo is Kornit’s response to a shifting production landscape – one majorly defined by a supreme demand for creative flexibility, local responsiveness, and sustainable profitability.

As the digital printing industry moves toward faster, more agile production models, traditional analog methods can feel increasingly rigid. In the world of direct-to-garment (DTG) printing, the demand for speed, scalability, and sustainability has never been greater. With the apparel industry’s shift toward on-demand, just-in-time (JIT) production, Kornit Digital’s Apollo technology is the game-changing solution. The Apollo offers a bridge between the speed of analog and the flexibility of digital, purpose-built for high-volume operations. Developed over several years with input from some of the world’s busiest print floors and launched in 2023 after years of rigorous beta testing, the Apollo is Kornit’s response to a shifting production landscape – one majorly defined by a supreme demand for creative flexibility, local responsiveness, and sustainable profitability.

The Apollo can most effectively be considered a platform – not simply a printer. It is part of a longer-term transformation in how garments are produced – one that’s increasingly automated, digitally connected, and localized. “Apollo represents a turning point for digital textile printing – not just in speed and quality, but in how it redefines production,” says Moran Levy, who along with EfiYohanani, leads the printer’s in-depth R&D and system management. “In five years, I see it setting a new standard for high-volume, on-demand digital workflows. Ten years out, it could be at the center of fully automated, interconnected production floors – linked to e-commerce, supply chains, and real-time order systems – enabling faster turnaround, real-time adaptability, and mass customization at scale.”

Designing from the Ground Up

Unlike many printers that are retrofits or reconfigurations of older tech, Apollo was built from scratch with high-throughput digital production in mind. Its automated workflow – from garment loading to curing – is designed to keep operations moving, minimizing downtime and labor. One thing that often surprises new users is how swiftly it runs. “The most consistent feedback we get is around the speed,” says Levy. “In some cases, customers have had to rework their entire floor management strategy just to keep up. Picking and staging garments efficiently becomes critical – otherwise the Apollo can outpace the rest of the process.” With a throughput of up to 400 garments per hour, the Apollo is capable of supporting annual production levels well into the seven figures – all with a relatively small footprint and a single operator. Effectively the most industrial-grade solution in the DTG space, the Apollo is ideal for companies with high production volumes – 550,000 impressions per year at a minimum, though it truly shines above 700,000. It’s well-suited for jobs that were traditionally produced using analog methods, like short runs of 200 to 300 units with a few colors. Those can now be done digitally, without sacrificing quality.

Digital Efficiency Meets Operational Flexibility

While speed is a standout, Apollo’s core strength may lie in its integration-ready design. It supports full automation via API, making it easier to connect to production planning systems, e commerce platforms, or digital order flows. Yet it’s equally functional as a standalone unit, allowing for localized or semi automated use depending on the operation. “Apollo was designed as a truly digital solution,” Levy explains. “It’s not just about speed – it’s about ergonomics, reliability, and how it fits into a modern workflow. Every decision was made to support efficient, high-volume production.” This balance of automation and manual flexibility makes it adaptable – whether you’re running a tightly integrated fulfillment network or scaling a mid-sized business into new markets.

Kornit is also tapping into new innovations regarding how businesses invest in the Apollo. With its all-inclusive SaaS “pay per-click” model, customers don’t need to purchase the printer outright. Instead, they pay a fixed fee per impression – covering the printer, consumables, and service. This frees up capital for businesses by removing the printing costs associated with each order. Customers only pay when they’re producing and selling, which makes it a more scalable, lower-risk model for businesses that are growing. This approach also simplifies planning. In contrast to traditional capital expenditure models – where the cost per garment can vary depending on ink coverage – the Apollo model offers a predictable cost structure, easing pricing decisions and financial forecasting. With the AIC model, the cost per garment is fixed and predictable, removing the variability often seen in traditional CAPEX setups. Kornit also assists in providing samples and detailed cost analyses so customers can actually visualize and map out a plan that fits their most agile and cost effective business needs.

Built-in Sustainability

For businesses trying to reduce their environmental impact, Apollo offers meaningful advantages. Its pigment ink system eliminates the water-intensive processes required by other technologies, while its built-in infrared dryer is designed to minimize energy waste through insulation and targeted heat distribution. More importantly, Apollo enables just-in time production – helping reduce overproduction and excess inventory by aligning output more closely with real-time demand. “It’s not only about greener materials or processes – it’s about making the entire production model more efficient and less wasteful,” emphasizes Levy. This kind of change can ripple throughout a supply chain, especially as more brands prioritize both environmental impact and production transparency.

For apparel decorators, fulfillment centers, and global brands alike, the move to digital is no longer a question of if, but how. With its focus on high-speed output, scalable automation, and environmental responsibility, Kornit’s Apollo is a thoughtfully designed answer for operations that want to grow with the best of the industry.