Groz-Beckert presents product portfolio for knitting, weaving and sewing

Groz-Beckert will be at the Techtextil presenting its comprehensive product portfolio and service offering in the areas of Knitting, Weaving, Felting,Carding and Sewing. In Knitting, Groz-Beckert is presenting its product portfolio for the technologies circular knitting, warp knitting and flat knitting, as well as customer-specific solutions. With system solutions from a single source, the company is responding to more stringent requirements for wear, load capacity of key components and the workability of different materials. Increased market penetration in warp knitting and the processing of materials such as metal and glass-fibre in flat-knitting mills call for custom-tailored solutions.

The Weaving department is presenting its comprehensive range of products for weaving preparation and weaving accessories at the Techtextil. A highlight of the portfolio is the PosiLeno® leno system, which boosts efficiency by up to 100 per cent. Moreover, an acrylic weaving machine mockup, the WeavingLoom, will provide insight into the operation of heald frames, healds, warp stop motions and drop wires. The jacquard heald is also demonstrated using the WeavingLoom. Made of mono wire, this product facilitates not only high densities but also a particularly gentle workmanship. In combination with the innovative thread eye, which is glued into the mono wire instead of welded, Groz- Beckert provides for uniform fabric quality and high machine efficiency.

Presenting the Quality Management INH (Ideal Needle Handling) at this year’s Techtextil, the area of Sewing is waving the banner of process optimisation. The patented process provides support in the handling of sewing machine needles during the entire sewing operation and has recently alsobeen offering a digital solution to document needle breakage: the Smart INH. The documentation system consists of two pieces of software, a mobile app and a browser, thereby facilitating the digital saving and storage of data sets as potential evidence. The Mobile Lab will be another Sewing highlight. It allows material samples to be examined and analysed directly at the Groz-Beckert booth.

INDUPRESS presents finishing and fusing equipments

NDUPRESS® stands for more than 40 years of tradition and experience in the field of complete equipment of garment factories worldwide. Its family business is your renowned partner for the production and processing of clothing.

IPN-TF-24 / Tunnel finisher

The INDUPRESS® high performance finishing device is constructed in modular version and can be assembled and operated in optimum way for different performance requirements and therefore offers an universal field of application for all garments like blouses, skirts, dresses, coats, trousers, anoraks, clothing for children, T-shirts, sweatshirts, sportswear, pad clothing, thermo jackets and so on.

In the steam modules the garments absorb enough steam to achieve good results even at high speeds. Also at garments made out of natural fibre. The fabrics (fibres) get softened with a measured and well directed amount of steam. In the next step the fabrics will be treated from top to bottom with air, fluid flow speed and temperature. All parameter can be adjusted individually and steplessly. A good finishing result can be achieved by a well balanced programming and exact dosage of the influential finishing parameter for different materials. All finishing parameter (temperature, steam quantity, steam quality) can be adjusted individually per chamber. Very energy saving because of automatic switching to Standby operation, if no garments will be feeded as well as perfect, high-class, mineral fully insulation.

IPN-HD-23-15B / sleeve finishing (Setting and finishing of sleeves)

Special pressing machine for setting and finishing of sleeves on men’s jackets with patented, pneumatic variable body for small and big sizes, adjustable to three size ranges (e.g. 46-50, 52-56, 58-64 and bigger) as well as three changeable sets of setting stamps for this three size ranges in addition one set of setting stamps for extremely small sizes and armholes.

Also the shoulder obliquity of the jacket body is variable, easy mechanical, adjustable in order to hang up the jacket perfect fitting to the model and order to justify the balance. The upper sleeve finisher which is mounted on the top of the machine frame can pass completely around the sleeve in three axes as well as rotary motion and so completely finish the sleeve. These movements can be programmed variable. A very flexible, to all directions adjustable side part holder supports the exact positioning of the jacket. Because of the back part holder with pneumatic positioning you will get a flat back at the armhole.

IPN-VHD-23-14B / shoulder pads (Fusing in of shoulder pads and form-pressing of shoulder)

Special pressing machine for fusing in of shoulder pads and form-pressing of shoulder. Because of accurately fitting pressing shapes the shoulder padswill be pressed perfectly and the shoulder will be perfectly in form. You can process different heights of shoulder pads through electropneumaticdjustment of the lower shapes (9 steps each 2mm, to be selected on the Touchscreen).

Battistella semi-professional and industrial ironing equipments

Battistella B.G. S.r.l. designs and sells semiprofessional and industrial ironing equipment. More than 40 years of experience have enabled the company to become a top player and spread its brand worldwide. Every machine is assembled with Italian components as “Made in Italy ” is a fundamental feature for the company, together with minimum consumptions and maximum performances. The wide range includes more than 100 models such as ironing boards, steam generators, spotting tables, dummies, toppers, presses and packing machines.

CIRCE shirt-finisher without boiler

Pneumatically operated shirt-finisher without boiler, to be connected to a steam source (min. steam 20kg/ h at 5 bar) and to compressed air (min. 7 Bar constantly). Fitted with 3hp blowing unit and 0,75hp vacuum unit for shirt positioning. Equipped with electronic programmer, dry iron for touch-ups, rotating arms and clamps, telescopic front paddle, rear paddle with photocell, pneumatic collar blocking/lateral tensioners, hot air battery. Suitable for the ironing of long and short-sleeved shirts.

Heated, vacuum and blowing foldable ironing board (120×45 cm) adjustable in height from 85 to 105cm (with spring), equipped with 3.4L stainless steel boiler, EOS iron, double safety valve, thermostat in case of damage, pilot lamp for water and discharge tap SIRIO/A pneumatic topper.

SIRIO/A pneumatic topper

Pneumatic topper with 10 lt. built-in boiler and pump, suitable for the ironing of washed out and casual trousers. Fitted with crosswise stretching evice and electronic/pneumatic size regulator with sensors, electronic programmer with display, steam atomizer. Also supplied with adjustable neumatic cylinders, leg-stretcher clamps with photocell, manual adjustment of air flow and 1,75Hp entilator- and internal and external tensioning of the 2 clamps.

Barudan computerised embroidery machine

Barudan Co., Ltd. is the manufacturer of Japan made computerised embroidery machine in Japan. Since 1959, Barudan has been producing the best built, most reliable embroidery machines in the world and proudly produced in Japan. It has exported embroidery machines to over 100 countries throughout the world with the corporation of Barudan Global Network.

Compact embroidery machines

Introducing new BEKY-CII Series. Barudan’s newest 2 through 8 head machines now have:

- New SH embroidery head (Smart Head technology) for higher performance and increased durability

- Servo motors for increased production and more power

- New K automat

Barudan’s new K Series multi-head machines were introduced in September of 2016. The new K automat features 10.4″ Colour Touch Screen, higher resolution and a 100 design, 70 mn stitch memory. User-friendly icons and an intuitive main screen provide quicker access to functions and features. It is available on all new Barudan multi-head machines. LAN and COM connectors are standard for Barudan networking along with 2 USB ports for devices such as barcode scanner, keyboard, mouse, hub and card reader.

Triple combination embroidery machines

Barudan offers multi-head speciality combination machines with various specifications and field sizes for chenille/embroidery, chenille/sequin, lockstitch zigzag and chenille/embroidery/sequin.

Big field embroidery machines

Introducing BEXS Series.

- Biggest embroidery field size in the world

- High speed

- High production

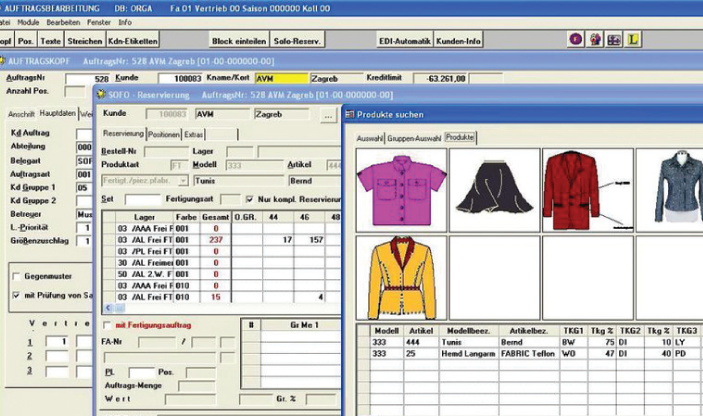

AVM Solutions’ ERP and integrated management systems

The AVM Solutions GmbH is part of the Human Solutions Group. The Human Solutions Group has 200 employees. Its products are sold worldwide, either directly by the Group or through partners in 50 countries.

ERP BOS – A guide from the point of sale to shipping

Apparel production is highly dynamic. ERP BOS completely maps the business processes, business structures and plans of apparel companies. And if required, the system adapts itself to market requirements – without expensive modifications.

SAM – ERP all the way to the point of sale

With SAM, apparel companies can perform on-site consulting and planning more efficiently. All the information about customers, products and all orderrelated data are available interactively in realtime. Field sales representatives, for example, can then create offers on-site – and request delivery dates and have them authorised by the office.

Lago – Quality and cost optimization in manufacturing

Lago by AVM ensures optimal quality for apparel manufacturers — and still saves cutting costs. Lago determines the optimal ratio between the actual material and labour costs in the cutting each collection piece.

Assyst solutions for efficient collection development in world of fashion

Successful products are customer-oriented and market-driven and the way to get there must be made increasingly faster and more cost-efficient. In intensive development sectors like Fashion and Mobility, this can only be achieved through the right product and size & fit information. Assyst GmbH Integrated 3D, CAD and PLM solutions for efficient collection development in the world of fashion.

Vidya-3D visualization in realtime with real body dimension data

Vidya offers you the best simulation of humans, cuts and fabrics on the market today, all based on realbody dimension data from iSize, CAD cuts and real material parameters. This means that apparel manufacturers can check size & fit, fabric behaviour, drape and prints — digitally and with no loss of time for different sizes — on the static or moving model.

PLM GoLive- Productive and efficient in development

With PLM GoLive, apparel manufacturers can control, manage and network link clothing the entire development process — from the initial idea all the way to quality control. Thanks to a practice-tested reference process, they can start working with the system right away and — only if necessary — precisely tailor the system to match their workflows.

Cad.Assyst- Pattern construction with exact draft quality for beginners and professionals alike

Cad.Assyst is a premium CAD system for product development. You can supplement the programme with function modules like Smart. Pattern for automated pattern development. MtM.Assyst and Lay.Assyst complement Cad.Assyst in customisation manufacture and manual placement.