Offering complete set of technologies for garment & fabric section

Established in 1995, Fabcare Garments & Textile Machinery Private Limited is one of the leading manufacturers and suppliers of finest and most diverse range of garments & textile machinery in India. Making of this range is done as per the set industry norms and guidelines, utilising the finest raw materials and modern machines. This ensures the product’s performance, service line, strength and capacity. The offered range is made up of the finest textile machines, washer extractor and washing machine, sewing machines, cutting & spreading machines which are widely demanded. In addition to this, the offered range is priced at the most reasonable rate possible.

Parted into several highly operational units, the state-of-the-art infrastructural facility at Fabcare helps it in managing the firm’s operations in the best possible manner. The facility has been laced with all the necessary machinery and equipment, which helps it in attaining a number of the firm’s predefined goals and objectives. In addition to this, the facility undergoes regular up-gradation, for reasons of attaining smoother and effective management of the firm’s operations.

The company is headed by mentor, Jitendra Arya, who has managed to attain a huge client base. His ability to understand the market and ability to manage in a highly commendable manner has been its most valuable asset. Fabcare recently became second distributors of Brother and Pegasus for looking after their sales and after sales service in Northern India. Besides, Fabcare will be the exclusive stockiest for these two brands machines in India.

“This is for the first time Brother and Pegasus have joined hands with a machinery manufacturer as earlier they were only associated with traders in India. We took their distributorship in August last year and since then we have been getting excellent response from our customers. In fact we hope to double our sales target in next one year,” said Abhinav Arya, Director, Fabcare Garments & Textile Machinery Private Limited.

“As far as quality is concerned, technically we are the best in our segment so to justify the same we choose to join hands with the brands which are best in their respective segments. As everybody knows, Brother and Pegasus are the leaders and best known for their high quality products in apparel and textiles industry. Apart from selling we will be taking care of the after sales service too,” he said.

Alongside these brands, the company has recently joined hands with KM for their cutting and spreading machines. KM is the sister concern of Hashima, a leading brand know worldwide for its quality products. Fabcare will be looking after their sales and after sales service on pan India basis. Recently, it has also been appointed by INA Computerised Hanger System for looking after its sales and service in Northern India. So, with all these recent additions, now Fabcare is offering complete set of technologies for fabric section.

Apart from these new additions Fabcare is well-known for its laundry solutions. The company last year introduced the Eco dyeing Splash series machine for garment and textile processing. “As a technology manufacturer it’s our responsibility to save water and energy, and keeping this in mind we have recently introduced the Eco dyeing Splash series machine for garment and textile processing. With this technology you can save up to 70 per cent water every cycle when you are doing washing or dyeing and 60 per cent saving when you are doing enzymes washes. People are already appreciating our Splash technology series which saves water, chemical, heat energy and waste water, and want their older machines to be changed with this new technology,” says Abhinav.

The company is agent of Primus – a leading laundry equipment manufacturer from Europe also. It also has a special wet cleaning solution with which you can do dry cleaning in the same machine. It is multipurpose equipment, which can save a lot of money, and the technology is far better when compared to hydro carbon and perc. It has opted for Primus so that every garment exporter who wants to do washing, cleaning and dry cleaning they can utilise the same equipment and save their factory space. They don’t need to invest 20-30 lakh rupees on one dry cleaning machine. When it comes to simple washing most of the garment exporters are doing only softening for that it introduced one Resinator which is dry to dry process where you can save 90 per cent water and chemical every cycle.

Exceptional fashion technology for economically-minded by Tukatech

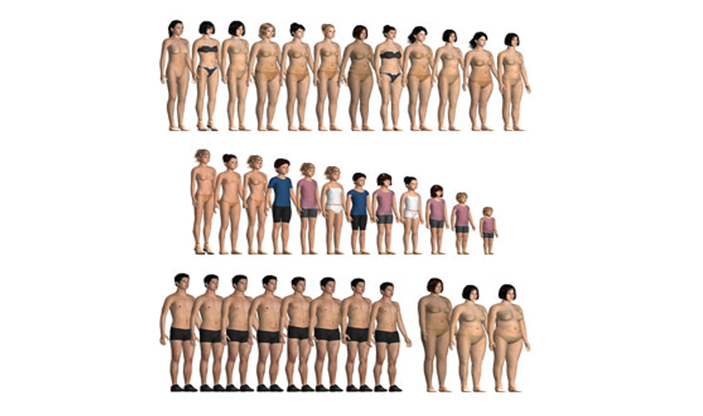

As the necessity for new technologies and processes becomes increasingly more apparent in the apparel industry, multitudes of designers and manufacturers of all sizes are turning to 3D solutions to increase efficiency in product development and enable effective global communication.

For many, the quest for resource-saving technology is often impeded with an ironic, but harsh reality: The initial start-up cost is just too expensive. To combat this deterrent, Tukatech Inc., USA, a global leader in fashion technology solutions (2D/3D CAD/CAM) for the garment and apparel industry, has launched the Enterprise Edition of its TUKA3D system for virtual product development for Indian Enterprises & Fashion Designers. This edition includes all the high-functioning 3D development capabilities at a more attainable price.

Ram Sareen, Tukatech’s Founder and CEO explained, “We know there are companies who want to adopt 3D technologies that just don’t have the capital. I’ve always believed that companies of all sizes should have the same access to advanced technology. We’ve seen the industry in California transformed by the affordability and availability of TUKAcad [for digital pattern-making, grading, and marker-making], 80 per cent of the California apparel industry uses TUKA systems. We hope to see a similar phenomenon in India with the onset of a more economical edition of TUKA3D.”

“We have dozens of vendors, brands, and retailers worldwide reporting amazing results with the implementation of TUKA3D in their product development process. “Going virtual” has allowed one vendor to reduce product development time from 90 days to only 7 days. Another has increased their first-sample acceptance rate from about 93 per cent to 99.8 per cent. So many companies have the innovative spirit and desire to achieve results like this. I can only imagine what will happen in the apparel industry globally with more attainable 3D product development and collaboration technology,” Sareen said.

Not only does TUKA3D EE provide an exceptional 3D product development solution with the TUKA3D software, but users can also take advantage of TUKAcloud, the web-based sample room for digital collaboration. This solution serves as a database of virtual samples, and is also a communication platform that enables product development to take place in a digital environment reminiscent of the traditional design process.

Without getting faster design and approval, we simply could not be in the fashion business. Designers are looking at uploaded samples at their convenience anywhere using mobile or other devices. They can see the 3d sample; zoom, pan, rotate the sample, just like they will in real life on a real person.

In addition there is a video showing how garment and fabric drapes, in tension and X-RAY mode enabling the viewer to see if there are any fit issues. All the colorways, print and embroidery placement can also be viewed. Upon analyzing the 3D sample and the video they can make comments, and the system automatically informs the pattern maker who can see and read the comments, make the required corrections and send the new sample almost immediately.

The system informs the individuals or the designated group to view and approve the final garment. Once the garment is approved for production, it now goes in the Asset Library so designers can use it for future development.

“We make over six million garments per month in hundreds of styles, the only way we can grow our business is to have more developments in a shorter time period with fewer people. This is what Tukatech has done with their solutions installed at all our facilities worldwide,” says Ranju Mahtani, CEO of the Hong Kong based THE EPIC GROUP.

“Today, there are many eCommerce retailers using TUKA3D for designing, developing, and uploading their realistic looking digital assets. They do not require a photo shoot, inventory, or warehousing; the best part is no markdowns. This is “Demand Manufacturing. This is the best way to be profitable and be ahead of everyone else. We are proud to be labeled as the “Disruptive Technologist” and want our customers to be number one,” says Ram Sareen.

There are companies who want to adopt 3D technologies that just don’t have the capital. I’ve always believed that companies of all sizes should have the same access to advanced technology. We’ve seen the industry in California transformed by the affordability and availability of TUKAcad [for digital pattern-making, grading, and marker-making], 80 per cent of the California apparel industry uses TUKA systems. We hope to see a similar phenomenon in India with the onset of a more economical edition of TUKA3D.

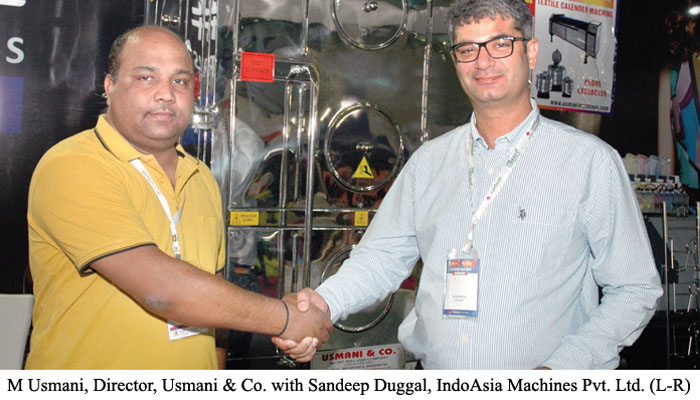

Indo Asia joins hands with Usmani for pre and post processing machine

Established in 2007, Indo Asia Machines Pvt. Ltd. (IAMPL) is a family run enterprise associated with the textile industry since 1950. Over the last nine years of its existence in textile machinery trading industry, it has grown from being a small textile company to a leading supplier of state-of-the-art textiles allied machineries including embroidery machines, water-jet looms, rapier looms, warping machines, digital printing machines and jacquard machines.

In all these years, the company has have carved a niche par excellence in the machinery market through consistently providing world class textile machineries with international standards blended with effective and prompt after sales services. The company recently tied up with Usmani & Co. for their pre and post process equipments.

“Since our inception, we have attained a steep growth in our business and have earned the recognition as one of the most efficient and reliable textile machinery suppliers of India. We have recently tied up with Usmani & Co. for their pre and post process equipments. They make fabric coating machine/padding machine, steam pressure ager, loop steamer, oil fired boiler heat fixation unit, industrial drying tumbler and many more equipments. We were looking for these kinds of machines for quite a long time, which are easily accessible and learnable technology for our customers. So now, our portfolio completes us with complete solution for sublimation and direct digital printing,” says Sandeep Duggal, IndoAsia Machines Pvt. Ltd.

Established in 1997, Usmani Co, offers wide range of quality products of modern ironing and laundry for garment industry. Eco-Steam garment finishing and laundry equipments are specially designed for low power consumption, minimum maintenance and maximum performance. Their products are available in a widerange and economical price. These products are fully automatic, semi-automatic and manual controls to the needs of big industry as well as small user.

“Being an Indian manufacturer, we are proving a good quality solution against imported machines, which are normally very expensive. Our company designs products that excel in sophistication, functionality, and are aesthetically pleasing and economically priced. We offer very cost effective pre and post technology solution, apart from our wide range of garment processing and finishing solutions,” says M Usmani, Director, Usmani & Co. “Surat is a very important market, which has invested a lot in digital textile printing in last few years. As a company, we wanted to focus on manufacturing and having dealer network all over India. With this tie-up we will be able to penetrate into this fast growing region and provide high quality affordable solutions to the customers here”

Growing application of laser in apparel industry

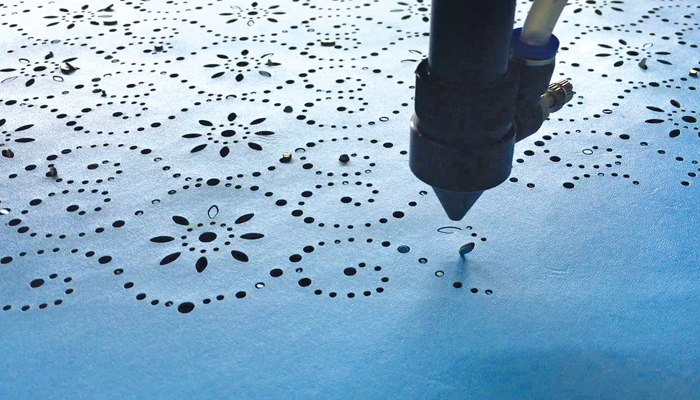

Laser is being used in apparel industry from nineteenth century for various garment manufacturing applications. There are several advantages of using laser over the conventional processes in cutting, engraving, embossing, denim fading and other applications. In addition, product damage potential is reduced, no/less consumables are needed and no problem of toxic by-product disposal as found in some processes. Today’s laser equipment is a result of continuous research and development of earlier products, which has undergone several changes. The initial laser systems were cumbersome, hard to run and difficult to maintain. However, the modern laser systems are simpler in operation and maintenance. Furthermore, the earlier systems were involved with more safety issues and needed the gasses to be constantly replenished. The garment manufactures around the globe should take the advantage of laser application in the post multi-fibre agreement regime to make their products more competitive. This review focuses on the technology of laser including various classifications. In addition it includes the applications of laser in garment manufacturing, their potential hazards and health related concerns.

Laser is being used in apparel industry from nineteenth century. Recently, the use of laser in apparel industry is increasing in cutting garment patterns, patterning designer neckties, 3D body scanning, denim fading and engraving leather. The major reasons for wide application of laser in garment industries may be due to reduced cost, flexibility and anti-counterfeiting. For example the artwork of high-end necktie producers are digitally stored rather than physical patterns to lower the theft risk. When needed, the digital patterns are converted into physical samples using lasers. Recently, the application of laser in denim engraving is increasing rapidly for value addition by replacing the traditional denim-distressing technics, which will take the denim segment to a height of sophistication that can never be realised by non-laser methods. The unique nature of the garment manufacturing industry needs laser applications, which combines performance with reduced cost by eliminating the handling systems used in non-laser workstations.

As an all-new process, there are several applications of laser in apparel industry. Laser engraving and cutting technologies now being widely applied in many garment industries, fabric production units, other textile and leather industries. Various applications of laser are discussed in the following section.

Fabric fault detection

When fabric is received at the stores of a garment production unit, the faults in the fabric can be detected with morphological image processing based on laser. Laser-based optical Fourier transform analysis can be used for fault detection in the fabric as the pattern is repeated at regular intervals. The fabric is focused with a laser and the diffraction gratings obtained from the periodicity of longitudinal an transverse threads in the fabric are superimposed. A Fourier lens is used to produce the diffraction pattern of the fabric. A second Fourier lens with same focal In laser cutting a laser is used to cut the fabric into the desired pattern shapes. A very fine laser is focused on to the fabric surface, which increases the temperature substantially and cutting takes place due to vaporization. Normally gas lasers (CO2) are used for cutting of fabric. The cutting machine (Fig. 2) includes a source of laser, a cutting head fitted with mirrors to reflect the laser beam to the cutting line, a computer to control the entire system and a suitable mean for removing the cut parts. The application of inert gases (N2, He) during cutting prevents the charring and removes debris and smoke from the cutting area. Like the mechanical cutting devices, a laser beam does not become blunt and need sharpening. Automatic single ply laser cutters are faster (30–40 m/min) than automatic multiple ply knife cutters (5–12 m/min). However, while cutting multiple plies, knife cutters are faster per garment cut and also cheaper.

The limitation of laser cutting is the number of lays of the fabric that can be cut by the beam. Best result is obtained while cutting single or a few lays, but the accuracy and precision is not obtained with several plies. In addition there is a chance of the cut edges to be fused together especially in case of synthetics. In some cases the sealing of the edges of cut patterns and sewn garment parts is essential to prevent fraying, where the laser plays the role. As in garment production facilities emphasis is given in multiple lay cutting, the laser cutting seems unlikely to become widespread. However, it is successfully used in cutting of sails where single ply cutting is the norm and a slight fusing of the edge of synthetics and woven materials is desirable. In addition, laser cutting is used in some areas of home furnishing.

Laser cutting is cheaper compared with the traditional cutting methods Furthermore, as the laser cutting doesn’t have mechanical action, high precision of the cut components at high cutting speed are feasible. The laser cutters are safer and include simple maintenance features, which can be operated for longer duration. The laser cutters can be integrated to the computer technology. It can produce the products at the same time when designing in the computer. Laser cutting machines have faster speed and simpler operation.

Laser cutting machines are suitable for cutting textile fabrics, composites and leather materials. They can operate for a wide range of fabric, which is not possible with die cutters. Hence, laser cutting machines are gradually been accepted in garment manufacturing. The features of laser applications include: Laser marking, laser engraving and laser cutting combined in one step

- No mechanical wear, hence good quality

- No fixation of material is required due to force-free processing

- No fabric fraying in synthetic fibres due to formation of fused edges

- It is clean and lint-free

- Simple process due to integrated computer design

- High quality raw materials and significant cost saving

- Extremely high precision in cutting contours

- High working speed

- Contactless, wear-free technique

- No chips, less waste

Objective evaluation of seam pucker

Garment appearance greatly influences garment quality. Seam pucker negatively affects the garment appearance. There are several methods to measure seam length magnifies and inverts the test sample image. A charge-coupled device (CCD) camera is used to capture the image. The data is transferred and stored in a computer. The computer programming helps in comparing the acquired images with the stored images by converting the image into binary mode. A fault is reported when the measured parameter is deviating from the standard. The severity of the fault depends upon the amount of deviation from the standard.

Laser cutting

After they were introduced in the 19th century, the fashion designers are widely adopting laser cutting in garment manufacturing. In synthetic fabrics, laser cutting produces well-finished edges as the laser melts and fuses the edge, which avoids the problem of fraying produced by conventional knife cutters. Furthermore, use of laser cutting is increasingly used for leather due to the precision of cut components. In fashion accessories such as jewellery, laser cutting can be used to produce new and unusual designs to produce a fusion of apparel design and jewellery style.

pucker, but the conventional rating system developed by American Association of Textile Chemists and Colourists (AATCC) is mainly used. The laser beam can measure the degree of puckering in garments by geometrical models. In this method a seam in the garment is scanned by a 3D laser scanner by putting the garment on a dummy. The laser head can be moved to any 3D space within a confined place by an operator. It is possible to scan the target object from different angles. A pucker profile of the scanned seam can be obtained by processing the image with a 2D digital filter. Physical parameters such as log σ2 (σ is variance) can be obtained from the pucker profile, which can then be linearly related to grade for seam pucker. From the objectively measured log σ2, the pucker grade can be objectively evaluated.

Mass customization

Mass customization

The term mass customization is used when custom-fit garments are obtained depending on the body dimensions and individual’s choice. The very first thing to mass customize garments is the accurate measurements of individual’s body.Lase scanning technology is one of the many techniques used for measurement. Laser scanning technology uses one or multiple thin and sharp stripe lasers to measure body size. Cameras are also used to acquire the scene and assist the laser scanner. The body measurements are derived by applying simple geometrical rules. In order to confirm the harmlessness of the beam, only eye-safe lasers can be used. Additional optical devices such as mirrors can be used to assist a single laser beam. The laser scanning unit (Fig. 3) consisting of light sensors and optical systems focuses on the human body for digitisation. The number of light sensors and optical systems can vary as per the positions of the body. For example, Vitronic1 body scanner consists of three scanning units that can synchronously move vertically along three pillars.

Laser-based denim fading

Laser-based denim fading

Now the age of fading of denim by sandblasting is becoming older as the new technology of laser fading is replacing it. In laser fading, a computer drives the laser beam to the material where marking or fading is required. The laser beam decomposes the dye and the resulting vapours are vented away. The material fades only where the beam impacts on the fabric. Commercially two types of lasers are being used: Solid based (wavelength of μm) and gas based (wavelength of 10 μm). The desired degree of fading depends upon the wavelength, power density, and pulse width of the laser beam. The method of marking or fading by laser is more environmental friendly as compared to acid washing or sandblasting.

- High working speed without mechanical contact

- No wear and tear of components

- Reduced waste

- Complete exhaust and filtering

- Exact contours possible

In laser engraving laser is used to mark or engrave an object. The process is very complex, and often computerised systems are used to drive the laser head. In spite of the complexity, very precise and clean engravings can be obtained with high rate of production. The technique does not involve physical contact with the engraving surface, hence, no wear and tear. The marks produced by laser engraving are clean, crisp and permanent. In addition, lasers are faster than other conventional methods used for product imprinting, which provides greater versatility in material selection. One machine can be used to cut through thin materials as well as make engravings on them. Laser engraving is used to engrave the printing screens, for hollowing, for creating pattern buttons, to engrave leather, denim etc. (Fig. 5). Pictures, flower patterns and even personalised signatures can be engraved on leather shoes, leather bag, wallet, leather belt, leather sofa and leather clothes, greatly increasing the added value of products. In addition laser engraving is used to create embroidered pattern in the fabric by colour fading and burning the fabrics. The low cost sealed CO2 lasers are preferred for laser engraving.

Denim engraving is another fast-growing application of laser using sealed CO2 lasers. The laser is used to create minute designs and patterns on denim fabric as well as finished denims. This technic can be used in place of the traditional technique such as sandblasting and acid washing. The accuracy and design flexibility is very wide, which can’t be achieved by the traditional methods. Lasers can produce 3D effects by techniques such as embroidering, embossing, or even apparent cuts, tears and mends. Any image that is created in a computer aided design (CAD), can be transferred to denim by suitable laser process. While using lasers, features such as good mode quality, high power stability, real-time control of laser power and fast pulse rise-time are the important parameters that can lead to colour change without charring or other damage to the fabric. Such damage could reduce the product life and cosmetically unacceptable. The advantages of laser engraving over traditional methods include:

Welded garment production

Welding is an alternative process of joining fabrics for garment production where the thermoplastic materials are joined together by the application of heat. The heat can be supplied by ultrasonic or by high powerful laser. The welded garment though weaker than the sewn counterpart, gives better appearance as it does not contain bulky seam and is more flexible.

Bar code scanning

The scanners used to scan the barcodes for product identification typically uses helium–neon (He–Ne) lasers. The laser beam bounces out of a rotating mirror while scanning the code. This sends a modulated beam to a computer, which contains the product information. Semiconductor based-lasers can also be used for this purpose. However, some of the recent manufacturers are using Radio Frequency Identification (RFID) based tags instead of barcodes due to certain advantages. The RFID tag can be processed quickly and it avoids the physical handling of the product as in barcode systems.

Laser marking

Laser can also be used in marking on various surfaces. The advantages of laser marking include fast, high precision and clear marking on products of varying contour and hardness. It can also be used for a wide range of organic polymers where precession can be obtained even with complex designs. Laser marking is durable and can be applied in clothing, leather and metals. Laser marking is considered to be the best choice for branded clothing and marking fashion accessories during processing.

Miscellaneous uses

There are many other applications of laser in apparel industry as discussed below:

- In some stitching machines (e.g., automatic welt pocket attaching machine) laser beam is engaged for automatic and accurate positioning of the welt and to make a slit across the fabric

- In some metal detection machines laser beam is employed to find if any needle part is there in the final finished garment

- Laser-engraving machine can engrave any decoration on the surface layer of any material, making the products looking high grade and exquisite

- Laser technology is gaining impetus in garment finishing which can produce various surface ornamentations without any wet processing. This technique is very accurate and can work fast with good repeatability and reproducibility

- The application of antimicrobial finishes into textiles has significantly improved compared to the past. Laser treatment was used for durable antibacterial properties on cotton fabric using silver nanoparticles

Forming a new Bond Welded and glued seams are making garments more functional and fashionable

Though the traditional thought has it that a “stitch in time saves nine,” what if there weren’t a stitch to begin with? It might be time to change the saying to something like “a touch of glue saves two” or “a welded seam is keen.” Just the thought of less bulky and lighter-weight gear and garments, all with more pleasing aesthetic lines (dare we say, fashionable?) is enough to get many designers “permanently bonded” to this new technology!

Adhesive Films

Bemis is the maker of Sewfree, one of the leading adhesive films being used to replace stitches for seams. Seamless technology, or products using Sewfree in construction, range from intimate apparel, lifestyle garments, technical outerwear, accessory items and even footwear, according to Chris Parlee, Marketing Manager for Bemis. Sewfree adhesive film is being used to bond fabrics and components—including everything from lace and meshes to ripstop nylons, all in one step—by such manufacturers in the outdoor industry as Arc’Teryx, Mountain Hardwear and Marmot. “I would say that Mountain Hardwear and Arc’Teryx are leading the pack here,” said Paul Kramer, Vice President of design and sourcing at Mountain Hardwear.

“There are some surfing companies that are big into the glue, but they are fairly basic in their approach. A lot of them don’t seem to be very technical.Arc’Teryx and Mountain Hardwear seem to be introducing the products and inventing new techniques and ideas for glued and welded construction.”Parlee said that Sewfree is being used to complement the stretch and recovery in what could be called “strategic” locations of activewear and fitness shorts.

In apparel, welding and bonding have been used for the past several years to apply pockets and zippers, make darts and pleats, hang pocket bags, hem garments, make stiffer plackets or panels, and apply waistcords. The primary advantage is that components, like pockets and zippers, can be placed without having to cut and sew the garment. Hems and plackets are also being glued to offer a clean look, eliminate seam tape, and prevent water leakage in the hem, flap or cuff.

“Many times these types of applicationsare done for aesthetic reasons,” Kramer said. “But, it is also important for technical reasons—in order to save weight, improve waterproofness or to increase breathability by eliminating layers of fabric. The goal is to weld or glue a waterproof/ breathable garment together so that seam tape can be eliminated, making the garment significantly lighter, softer and more breathable

Welded Seams

Welded (seamless) construction is being used in sleeping bags, tents and packs. In sleeping bags, baffles are bonded to the shell fabric to prevent the shell from being punctured; however, this is only now beingdone on fabrics that have a laminate or coating, so that the waterproof integrity of the outer fabric is maintained. Similar methods for garment construction are used, but with some slight modification. Mountain Hardwear considers the details of its construction method to be proprietary. “In tents, Mountain Hardwear is using seamless construction to attach a coated floor to a fly. This eliminates the need to tape, saves weight and also makes new construction techniques possible,” said Kramer. “Currently, welding or gluing critical seams for tents is not possible due to the extreme stresses involved.”

Methods To The Madness

There are two basic methods for applying bonded and welded seams. The first method uses an adhesive film (thermoplastic film) for bonding two fabrics (substrates) together. In this technique, the adhesive film is slit into tapes and applied in strategic locations, or the adhesive film can be laminated to wide-width fabrics, Bemis’ Parlee explained. “During the process, the adhesive is tacked or laminated to one of the substrates, and the second substrate can be laid on top,” he said. “Then, heat and pressure activate the adhesive. The film melts and penetrates into the fabrics and creates a bond between the two.”

The second method involves welding two fabrics with radio frequency/ ultrasound. Ultrasonic echnology involves the creation and channeling of high frequency vibratory waves that cause a rapid buildup of heat in synthetic fabrics. The heat can be used to weld, bond, cut or slit the materials, asdesired. The ultrasonic bonding process is fast, accurate and efficient.

Janet Devine, President of Sonobond Ultrasonics, a supplier of ultrasonic equipment for bonding textiles, said, “With ultrasonics, the need for consumables such as adhesives is eliminated. In addition, the production runs efficiently because there is no need to allow time for glues or other solvents to dry.”

There are many advantages of bonding or welding, according to Parlee. “Bonded garment technology allows for a seamless look and feel,” he said.“A slimmer profile and less abrasion to the enduser are achieved with bonded seaming. A bonded seam can also initiate the stretch and recovery of the fabric, more so than stitching. A bonded seam can be waterproof, and a bonded garment typically weighs less than a sewn garment.”

Bonding also reduces or eliminates the amount of thread used so there are no threads to wear out in a seam, Kramer said. “Then, you can also put otherthings into the seams, like elastic. The seam can stretch, whereas most seams that are sewn and taped do not stretch.” Additionally, bonding allows.

Cheran Machines marks silver jubilee of successful journey in India

Cheran Machines India is one of the leaders among manufacturers and exporters of high performance textile printing machinery and garment printing machines for various requirements. Cheran is an ISO 9001 – 2015 certified company, located in Coimbatore, Manchester of South India. With a strong commitment for quality, it has built strong brands recognised for innovation, user friendly features and superior performance. The company recently celebrated 25th anniversary of its successful journey in India.

“I would like to thank all customers who supported us in this journey. Last few years have been excellent as we have lots of wonderful customers not only in India but overseas also. We are looking ahead to the future with a spirit of confidence and motivation. We are convinced that we will continue our successful path by working together to enhance our existing strengths and to put our customers’ benefits into the focus of our operations,” said R Mohan Kumar, Managing Director, Cheran Machines India Pvt. Ltd while speaking over the company’s silver jubilee.

The product superiority and proven quality have helped the company to earn clients all over India and in overseas markets like Bangladesh, Egypt, Madagascar, Nepal, Sri Lanka, Thailand, Vietnam and in the Gulf region. Cheran has very strong research and development team with dynamic engineers and CAD computer graphic facility. After having felt of customer needs in the competitive garment/ textile printing sector, Cheran’s design engineers have dedicated their career in designing & developing customer requirements and simultaneously it is increasing its client base in leather, automobile, rexin, nylon medical and supportive industries.

“In order to satisfy our valued customer we have strong and technically trained service engineers backed with all latest technological and telecommunication supports to provide effective after-sales-service inclusive of dealer network,” said Mohan. Cheran is always confident in committing full support before, during and after sales. The company works with the mission of achieving excellence in quality and maximising customer satisfaction by offering a wide range of high performance and efficient printing machines catering to the textile and garment industry. “We owe our success to the extensive industry knowledge, improved technologies and customer-focused approach,” added Mohan.

The years of experience that has gained in the industry has been based on the strong foundation of product quality and repeatable satisfied customer. A rigorous quality control system in place has always ensured highest standards of quality. This achievement is primarily due to the support received from its customers, the company says. “Firstly when we look back at the past 25 years, Cheran has faced numerous obstacles to success, including social and economic turbulence.

But we successfully overcame these obstacles and with the support of our customers and team. That’s why we’ve been able to continually develop as a manufacturing company. And also we strongly believe that there were three key factors for our success. The first being “the support of our customers,” the second was “the perseverance of our employees” and third “sheer luck”. Without just one of these three components Cheran might not have made it to today,” said Mohan. The company deploys an online quality monitory system to get the stages from raw material purchase to finishing the product with qualified technical personnel to overseas the process, it is ensured that only the finest quality product reaches the customer. “We will always deliver only the quality products demanded, responding to customer’s needs with on time delivery of the quantities requested. We will meet all new challenges with an open mind but take past experiences into account. We think of this 25th anniversary as a second start and the entire company will strive for further development. Cheran will continuously strive to remain a company worthy of your trust in the next 25 years,” said Mohan.

The company commits the following in pursuit of satisfying our customers: Design and manufacture of safe reliable product, Adhering delivery commitments, Adopting systems to direct people, Customer support throughout the product life cycle, Continual improvement of products, process and systems, and Enhancing employee competence to suit the changing demands.

“We are one of the leaders in this segment, not only having dealer network in India but Sri Lanka also, so that’s the edge we have. We have a crazy pool of engineering talent so we hope for a good future ahead. We are the one stop shop for best technologies, reach and service, so would like to remain the largest supplier of equipments in India,” said Mohan.

At present, the company is having offices in Coimbatore and Tirupur apart from dealers network in New Delhi, Ludhiana, Mumbai, Kolkata, Indore, Surat, and in overseas at Sri Lanka. In the journey towards excellence, the company regularly participates in all major trade shows in India and overseas like IMB – Germany, Aamatex – Singapore to market its products.

Cheran’s various product offerings include: Pneumatic stretching clamp, mechanical stretching clamp, stirrer motor, screen washer |washing booth, “X-wel” exposing machine, screen dryer, manual printing machine, micro registration printing machine, electric flash curer, electric dryer / conveyer curing, diesel – gas dryer, digital heat transfer / fusing machine, sleek / digital twins (heat transfer / fusing machine), cute / crystal machine, roll heat seal machine, jumbo / sublimation transfer with vacuum bed machine, flat screen printing machine, Cheran’s swift roll to roll sublimation transfer machine, Cheran’s jumbo / sublimation transfer machine with double tray.