Hey, it is not rocket science!

Hey, it is not rocket science!

Industrial production processes are precisely planned by engineers, technologists, logistics analysts. Steps are carefully measured and planned, their timing accurately estimated and the material is stocked and delivered to the production in time. This is necessary because of tight profit margins: poorly designed processes may result in making a loss on the job.

Yet, the embroidery industry frequently suffers from poorly estimated jobs, delays and unexpected overheads. Engineering precision not yet touched our area in most companies. There are difficulties about how to estimate the actual costs of a job at the design phase. This is important, so we can have better management in our factory and also that we better understand the cost factors.

Here are a few ideas about how embroidery designing can provide cost estimates for the production, so resources can be prepared. It is not rocket science but we need to use science built into the design software to improve our Production Management.

Basic numbers

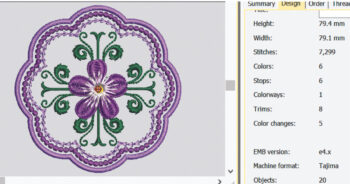

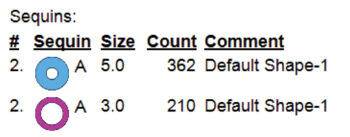

Basic cost factors in a design: number of stitches, color changes, trims, jump stitches. Sometimes, number of sequins, beads. The number of stitches is a basic number, multiplying them by the machine speed (stitch per minute) will give us the core value of the running time.

Basic cost factors in a design: number of stitches, color changes, trims, jump stitches. Sometimes, number of sequins, beads. The number of stitches is a basic number, multiplying them by the machine speed (stitch per minute) will give us the core value of the running time.

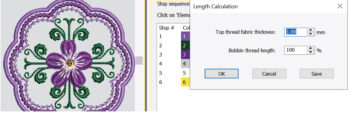

Another estimate that is necessary for production is to know how much thread the design will use. The design software can give the Production Manager this information in meters for each thread color. The stitch length calculation parameters depend on the bobbin tension, the top tension, the average machine speed and the type of thread

we use. Some software give you a formula, where you can adjust parameters and run tests, compare the estimate with the result and adjust the formula until you get a close result. From then you can easily estimate the thread usage.

Estimating Running Time

The basic number here is “machine speed”. Most embroidery machines are set to much lower speed than the maximum speed, this is to reduce thread breaks and reduce the thread tension and therefore fabric distortion. For logo work, higher speeds are acceptable because the logos have backing fabric, to stabilize the design against distortion but fashion work, is mostly done on a single fabric layer without backing. Today, embroidery machines equalize threat tension against speed. The machine slows down on longer stitches, so the thread tension caused by the thread feeding/tensioning mechanism stays even.

The basic number here is “machine speed”. Most embroidery machines are set to much lower speed than the maximum speed, this is to reduce thread breaks and reduce the thread tension and therefore fabric distortion. For logo work, higher speeds are acceptable because the logos have backing fabric, to stabilize the design against distortion but fashion work, is mostly done on a single fabric layer without backing. Today, embroidery machines equalize threat tension against speed. The machine slows down on longer stitches, so the thread tension caused by the thread feeding/tensioning mechanism stays even.

This way the quality of long and short stitches is about the same. Still, the proportion of long stitches and short stitches in a design can affect the overall stitching time. It is advisable to keep the stitches in a design relatively short (under 7 mm).

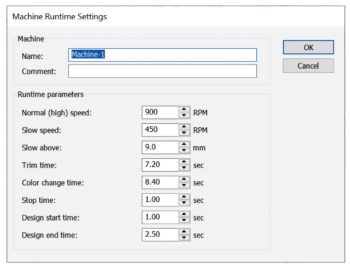

The embroidery design software usually provides stitch estimate and some also provide machine running time estimates as well. You can setup the running parameters for each machine, and fine tune them with test designs until you get estimates that are within 10-15% of the actual run time.

Embellishment usage

Embellishment usage

It is possible to estimate the amount of embellishment (sequins, beads) the job will take. If you need to report the costs of the job later, such design numbers can help. For example, the Wilcom Production Worksheet has such report.

Summary

The above are just a few ideas and examples how the Production Manager can collect data from the Design Department in order to plan the production of a new design, make sure that there is enough stock of thread and other parts and also can calculate the costs of the job. This can also help to provide better quotation for future jobs.

(By Janos Horvath, Vice President International Sales, Wilcom)