ANAADIH VINCOM – Revolutionizing Indian textile industry with Cutting-Edge solutions

ANAADIH was established in 2013 by Udai Kumar Agarwal, a seasoned professional in fabric and garment manufacturing. Recognizing the need in Kolkata for cutting-edge solutions in the industry, he embarked on a journey to provide the best products and services. Currently, ANAADIH is in association with renowned global brands such as Creora, Brother, Kansai, Duma, Bierrebi, Weideshi, Santec, Shanggong, Texfab and CHL, among others, known for their superior quality products on a global scale.

ANAADIH was established in 2013 by Udai Kumar Agarwal, a seasoned professional in fabric and garment manufacturing. Recognizing the need in Kolkata for cutting-edge solutions in the industry, he embarked on a journey to provide the best products and services. Currently, ANAADIH is in association with renowned global brands such as Creora, Brother, Kansai, Duma, Bierrebi, Weideshi, Santec, Shanggong, Texfab and CHL, among others, known for their superior quality products on a global scale.

In order to expand our reach across India, we have inaugurated our branch office in Tiruppur, the country’s leading hub for garment exports, offering immense potential for growth. The scarcity of labour has increasingly necessitated automation, prompting us to align with the evolving needs of the industry and contribute significantly to its advancement.

ANAADIHH’s recent association with DUMA, CHL and WEIDESHI, as their sole selling agent for India, has been with the singular purpose of introducing their most innovative, reliable, global quality standard and user friendly products to the Indian consumers to achieve a smooth production process.

DUMA

Since 2005, DUMA has become a world-renowned brand for its continuous technological innovation and substantial investment in R&D. It has achieved remarkable results in the sewing industry. The company has won the CISMA Demonstration Product Certificate many times, and has been rated as a national high-tech enterprise. It has also successfully obtained many quality standard certifications and holds 133 patents, including 17 invention patents, demonstrating its strong technical strength. DUMA has a rich series of product matrix, covering lock stitch sewing machines, overlock sewing machines, flatlock sewing machines, template machines and other special machines. With nearly 100 industrial sewing machines, it meets the production needs of different customers with their varied applications.

Since 2005, DUMA has become a world-renowned brand for its continuous technological innovation and substantial investment in R&D. It has achieved remarkable results in the sewing industry. The company has won the CISMA Demonstration Product Certificate many times, and has been rated as a national high-tech enterprise. It has also successfully obtained many quality standard certifications and holds 133 patents, including 17 invention patents, demonstrating its strong technical strength. DUMA has a rich series of product matrix, covering lock stitch sewing machines, overlock sewing machines, flatlock sewing machines, template machines and other special machines. With nearly 100 industrial sewing machines, it meets the production needs of different customers with their varied applications.

Since DUMA registered its stepping motor technology patent in 2015 and launched two stepping motor enabled sewing machines in the market, it has led and accelerated the stepping motor era for others to follow. DUMA’s entire product line has deeply integrated stepping motor technology to achieve precise control, highly integrated functions, convenient operation, and ultra-low-frequency operation. It is widely used in various sewing scenarios, effectively simplifying manual operation processes and greatly improving production efficiency.

In 2025, DUMA is set to disrupt the industry again by introducing full range of bird’s nest-free industrial sewing machines, completely solving the troublesome problem of bird’s nest, thread balls in the sewing process. The seams will be smooth and unobstructed, greatly reducing the defect rates and eliminating the need for manual trimming of thread ends. The stitches will be even and beautiful, significantly reducing time and labour costs. It is expected to set off a new revolution in the sewing field and lead a new trend in industry development.

CHL

Guangzhou Cheng Helong Printing Machinery Co. Ltd. (“CHL”) was founded by veterans of the printing industry with more than 20 years of experience. CHL is a high tech enterprise, holding many utility model patents, and it continuously engages in R&D for the manufacturing and sales of automatic oval printing machines and accessories. From colour separation, film making, printing materials, printing machinery to sewage treatment, CHL provides omnidirectional services and solutions.

CHL has a strong inhouse R&D team which includes experienced and capable mechanical designers, program designers, electrical engineers, application engineers, assembly engineers and after-sales engineers. With a laser focus on quality and innovation lead development, CHL creates oval printing machines with humanized designs aimed at providing simple and convenient operations.

Leveraging its technical expertise and hunger for innovation, CHL has introduced its XC Multi-Functional Intelligent Printing Model which is revolutionizing the screen printing industry. It has the World’s 1st Automatic Frame Setting and Print Positioning Technology which coupled with its Memory Function has significantly reduced the time consumed and production loss faced while positioning the screens during repeat printing. Further, with its Automatic Screen Lifting feature, it is able to automatically lift the screens for High Density prints during each successive round of printing, eliminating the need for manually lifting the screens. The result is increased production, reduced labour reliance, and accurate prints. The XC Model is capable of printing on various materials such as transfer label film, shoe, leather and can use different types of inks such as waterbase, plastisol, silicon, etc.

WEIDESHI

WEIDESHI

Established in 2005, WEIDESHI is the Global Largest Ironing Table & Boiler manufacturer and an expert in single phase motor industrial fans. With more than 20 years of focus on ironing tables, steam boilers and factory air ventilation management systems, WEIDESHI can provide customers with a comprehensive solution in the field of ironing and ventilation.

It boasts of an 80,000 square meter workshop employing a staff force of over 400. It is the first manufacturer in the industry which independently develops and produces its motors, water pumps and impellers. Further, it is the first manufacturer in the industry to use CNC punching, laser cutting, fully automatic bending, robotic automatic welding and automatic spray line for the production of its machines.

WEIDESHI has the remarkable achievement of being the first manufacturer to have annual sales of over 1,00,000 Ironing Tables and 50,000 Steam Boilers. Now, ANAADIH in its partnership with WEIDESHI, has launched its entire range of quality products for the first time in India, at attractive prices, to cater to the ever rising demands of the Indian textile industry.

SCOPE by Studio Next – Revolutionizing garment manufacturing with affordable automation

Garment manufacturers in India face numerous challenges, including the high cost of advanced machinery, inconsistent product quality, and inefficiencies in production. Many struggles with limited access to reliable automation solutions, forcing them to choose between exorbitant investments in premium technology or settling for low-quality alternatives that fail to deliver consistent results.

Garment manufacturers in India face numerous challenges, including the high cost of advanced machinery, inconsistent product quality, and inefficiencies in production. Many struggles with limited access to reliable automation solutions, forcing them to choose between exorbitant investments in premium technology or settling for low-quality alternatives that fail to deliver consistent results.

Recognizing these issues, SCOPE was established to bridge this gap and empower manufacturers with cutting-edge yet affordable solutions. At the forefront of this revolution SCOPE is dedicated to redefining garment cutting room automation with a perfect blend of quality, reliability, and affordability. Powered by Studio Next – India’sLeading CAD/CAM Solution Provider, SCOPE combines innovative offerings and a customer-centric approach to set the stage for a new era in manufacturing.

The Scope Pro Series Autocutters are engineered to deliver unmatched performance in mass production environments. These cutting-edge machines are built to handle even the toughest challenges. The Denim Cutter features unmatched cutting capacity with a cutting height of 7 cm, these machines effortlesslyslice through up to 90 plies of denim. The Autocutter is designed to efficiently cut fabric layers while advancing them, ensuring precision and seamless operation. The denim cutter also features knife intelligence, a cutting-edge blade technology designed for exceptional precision, minimized wear, and maximized operational uptime. This powerhouse of innovation guarantees reliability and consistency, making it an essential tool for manufacturers striving for excellence.

This versatile spreader supports both rolls and folded fabrics, combining dual-purpose functionality with a user-friendlytouch displayfeaturing multi language support. Designed for cost-efficiency, it offers easy installation, low training costs, and minimal maintenance. A digital dashboard provides real-time factory insights, improving operational efficiency and order handling. With IoT integration and remote monitoring, it connectsseamlessly to apps, PCs, and production dashboards, enabling streamlined and intelligent factory management.

Empowering Manufacturers with Hands-On Experience

Empowering Manufacturers with Hands-On Experience

At Studio Next, we recognize the critical role of informed decision-making in revolutionizing garment manufacturing. To support this, we have made a significant investment in establishing a state-of-the-art live demo center in Vasai (Mumbai). This advanced facility enables garment manufacturers to experience live demonstrations of cutting-edge machines and conduct production tests—all at no cost. By providing this resource, Studio Next is driving a transformation in the industry, empowering manufacturers to transition from low-quality, high-cost solutions to superior, affordable technologies tailored to their needs.

Cutting Job Work Services: From Concept to Creation

Studio Next elevates convenience with its cutting job work services, providing manufacturers with a hassle-free solution. Simply bring your designs and fabric, and we’ll handle everything—from precise pattern creation to delivering accurately cut pieces. Our streamlined process saves both time and resources, ensuring efficiency and excellence at every step.

Join the SCOPE Revolution in Garment Automation

With the groundbreaking Scope Pro Series Autocutters, HX Series Spreaders, a state-of-the-art live demo center, and professional cutting job work services, we are setting new standards in garment manufacturing.

In this edition of GTE, we are thrilled to showcase our comprehensive range of advanced solutions, including Garment CAD Software, High-Speed Inkjet Plotters, Cutter Plotters, Fabric Loaders, Automatic Fabric Inspection Machines, Automatic Fabric Spreading Machines, and Automatic Fabric Cutting Machines.

For further details visit us at Stall No. B-14A and experience the future of garment manufacturing with SCOPE. Redefine your production possibilities today.

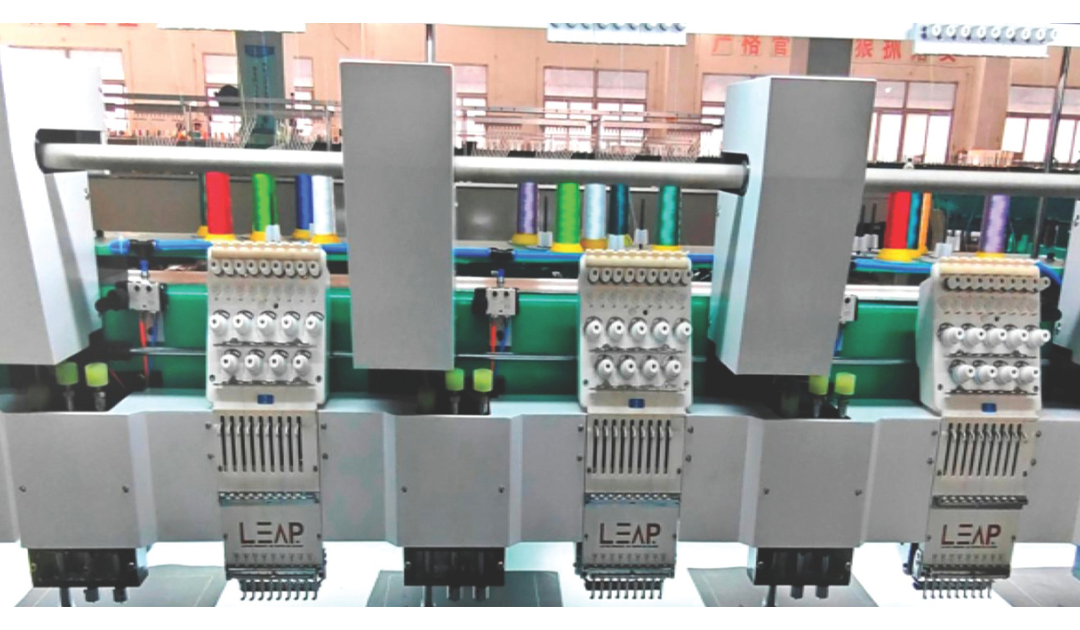

Textile Technologies Leading innovation in Embroidery and Quilting Machines

We at Textile Technologies are a leading supplier of specialised embroidery machines and multipurpose quilting embroidery machines serving the textile industryfor 15 yearsin Delhi/NCR and Punjab. Our head office is at Noida, serving Delhi NCR and Panipat. We have partners in South India, West India, Dubai, and many more markets. We have experienced almost 80% growth in thisfinancial and we still have 2 more monthsto enhance that, we are sure that the Indian Business is growing and we are keeping our pace to match the expectations of our customer.

We have many firsts to our credit, we were the first ones to successfully run Mixed Chenille Embroidery Machinesin North India and the tradition continuesfor us, thistime we are introducing following new technologies at GTE 25:

Leather Embroidery and Perforation Machines (LEAP)

LEAP is a very innovative product and has been introduced in India for the first time and we have received tremendous response from the car seat cover industry and furniture companies, we see a lot of adaptation from the leather garment manufacturers also.

Mixed Embroidery and Tufting Machines

Another Gem from our side is a unique style of embroidery, primarily for garment and home furnishing industry, the machine will be displayed at GTE 2025, and you can see the live demo and performance of the machine. Other machines on display are Mixed Chenille which is already our star seller and very new Roll to Roll Quilting Embroidery Machines with TWIN needle effect.

Range of products is big and amazing

We have been known in the industry for the very superior and prompt after sales service record and our retention of customers is over 90 percent, which is “Once our Customer, Always our Customer”

Elevate your style with Parneet Textiles’ customizable vintage neckties and customized woven jacquard fabrics

Parneet Textiles proudly presents its latest collection of vintage-inspired designer neckties, crafted to meet the highest standards of sophistication and individuality. These ties blend classic charmwithmodern innovation, creating a product that not only stands out but also reflects the wearer’s personality.

Parneet Textiles proudly presents its latest collection of vintage-inspired designer neckties, crafted to meet the highest standards of sophistication and individuality. These ties blend classic charmwithmodern innovation, creating a product that not only stands out but also reflects the wearer’s personality.

Each necktie in this collection is designedwith precision and care, using premium woven jacquard fabrics. Our designsincorporate intricate patterns, bold colors, and a vintage aesthetic that resonates with timeless elegance.For customers who seek exclusivity, we offer full customization options for design, pattern, weave, and color. Whetheryou envision a statement piece or a subtle addition to your wardrobe, our ties can be tailored to your exact requirements.

Innovation lies at the core of our craftsmanship. To ensure the highest quality, we have sourced yarns that rival silk in both look and feel, offering luxurious textures and durability. These carefullyselected yarns provide a premium finish, ensuring our ties are as comfortable as they are stylish.

Ourstate-of-the-art manufacturing facility has been enhanced with high-value machinery, allowing usto meet growing demandsfor customized, high-quality products. This upgrade enables us to produce not only bespoke neckties but also specialized fabrics such as brocade, interlining, and high-end designer textiles. Every product is crafted with meticulous attention to detail, meeting the needs of our discerning clientele.

Parneet Textiles’ commitment to quality extendsto offering low Minimum Order Quantities(MOQ), making our bespoke services accessible to businesses and individuals alike. This ensures that every customer, no matter the scale of their needs, experiences the luxury of tailored craftsmanship.

Embrace the art of individuality and elevate your style with Parneet Textiles’ new collection. Discover the perfect blend of tradition, innovation, and luxury in every piece.

Latest Innovation from ABH Biochem Pioneering Sustainable Textile Chemistry

At ABH Biochem, we are committed to innovation and sustainabilityin textile chemistry. As a leader in high-performance textile chemical solutions, we continuously develop products that enhance fabric quality while being environmentally responsible.

At ABH Biochem, we are committed to innovation and sustainabilityin textile chemistry. As a leader in high-performance textile chemical solutions, we continuously develop products that enhance fabric quality while being environmentally responsible.

Revolutionary Natural Mineral Oil-Based Softeners

We are proud to introduce our latest breakthrough, Natural Mineral Oil-Based Softeners – ABROSOFT-ECO N. It is designed to provide superior softness, luxurious handfeel, smoothness, and durability, these cutting-edge softeners are a game-changer for textile manufacturers who prioritize both performance and eco-friendliness.

Key benefits of our Natural Mineral Oil-Based Softeners:

• Exceptional Softness: Achieve an ultra-smooth and luxurious fabric feel

• Eco-Friendly Composition: Made with sustainable, biodegradable ingredients

• Enhanced Durability: Provides long-lasting softness even after multiple washes

• Non-Yellowing Formula: Preserves fabric brightness and appearance

• Versatile Application: Suitable for a wide range of textiles, from cotton to synthetics

At ABH Biochem, we understand the evolving demands of the textile industry and strive to provide sustainable solutions without compromising on quality. Our natural mineral oil-based softeners are an excellent choice for textile manufacturers looking to elevate their products while reducing environmental impact.

Revolutionizing Sulphur Dye Oxidation

ABH Biochem, a trusted name in textile chemical manufacturing, proudly introduces latest breakthrough in sulphur dye oxidation—a game-changer for the industry. The newly launched advanced oxidation agent eliminates the need for sodium Sulphide, acetic acid, and hydrogen peroxide, making the process more efficient, cost-effective, and eco-friendly.

Key Benefits:

• Completely Removes Sodium Sulphide – Say goodbye to traditional oxidation challenges

• No Acetic Acid or Hydrogen Peroxide Required – A safer and more sustainable approach

• Optimized Dosage (0.5%) – Low usage, high performance

• Powder Form (Crystal Appearance) – Easy to handle and apply

• Fabric & Dyeing Integrity Maintained – Ensures excellent dye uptake without damage

Upgrade your sulphur dyeing process with ABH Biochem’s latest innovation! Experience efficiency, sustainability, and superior results like never before.

Vee Kay Enterprises launches Make in India Digital Textile Printing Machine

Established in the year 1985, Vee Kay Enterprises, a name synonymous with complete solutions in digital printing for various segments, including digital textile printing, launched their first-ever Made in India digital printing machine at the recently concluded GARFAB–TX exhibition in Jaipur, India. With thislaunch, the company proudly joined the “Make in India” initiative, which encourages Indian entrepreneurs to promote technology developed and manufactured locally and curb imports that hugely dent our country’s economy.

Established in the year 1985, Vee Kay Enterprises, a name synonymous with complete solutions in digital printing for various segments, including digital textile printing, launched their first-ever Made in India digital printing machine at the recently concluded GARFAB–TX exhibition in Jaipur, India. With thislaunch, the company proudly joined the “Make in India” initiative, which encourages Indian entrepreneurs to promote technology developed and manufactured locally and curb imports that hugely dent our country’s economy.

Speaking to our editor, Mr. Amit Wadhwa, Vee Kay Enterprises,we have launched the reactive printing machine and were elated with the response received for their machine,which matches globalstandardsin terms of quality and performance.

He furtherwent on to add that their entry-level machine, launched in 4- and 8-head versions, is priced quite competitivelyin comparison to Chinese brandswith similar specifications. The price advantage not just comes from being made in India, but also from the expertise and capabilitiesthat Vee Kay Enterprises has built through more than 4 decades of understanding the market needs.

This machine is equipped with a RICOH Gen6 head, which remains the popular choice for major brands for being a highly reliable, stable, and performance orientated printhead that is also priced competitively. In terms ofspeed, the machine exceeds customer expectations by matching every feature that one might find in a 4- or 8-head machine. The production speed for a 4-head machine is 65sqm/h, while an 8-head version is 130sqm/h.

On being asked about the future of pigment inks, Mr. Amit felt that with stricter norms on environmental concerns and water conservation, pigment printing will steadily gain momentum as global demand for sustainable garments is already on the rise. The advantage of pigment printing is that it considerably reduces water usage while eliminating pre- and post-treatment processes. Also, besides garments, pigment printing can open up newer markets such as bags, jute, and footwear, a market that Vee Kay Enterprises would also like to tap in the future. Regarding the cost of the machine, Mr. Amit revealed that while the 4-head machine is priced at 40 lakhs, the 8-head version will be priced a bit higher at around 50 lakhs. In the future, though, as the volume builds up with demand, the prices might significantly reduce, making it even more affordable. Cost-wise, also, our machine offers the advantage that customers can save around 20 to 25 percent on freight and customs duty. In addition, there are inherent advantages to buying this machine, as after-sales service support and availability of spares with quick response will greatly reduce the downtime and boost production.

On being asked about the future of pigment inks, Mr. Amit felt that with stricter norms on environmental concerns and water conservation, pigment printing will steadily gain momentum as global demand for sustainable garments is already on the rise. The advantage of pigment printing is that it considerably reduces water usage while eliminating pre- and post-treatment processes. Also, besides garments, pigment printing can open up newer markets such as bags, jute, and footwear, a market that Vee Kay Enterprises would also like to tap in the future. Regarding the cost of the machine, Mr. Amit revealed that while the 4-head machine is priced at 40 lakhs, the 8-head version will be priced a bit higher at around 50 lakhs. In the future, though, as the volume builds up with demand, the prices might significantly reduce, making it even more affordable. Cost-wise, also, our machine offers the advantage that customers can save around 20 to 25 percent on freight and customs duty. In addition, there are inherent advantages to buying this machine, as after-sales service support and availability of spares with quick response will greatly reduce the downtime and boost production.

He further added, “China, where online business is thriving, and in the future, a similar trend in India will only help promote the growth of textile digital printing, which is preferred in this era of fast fashion, quicker delivery, and better production planning, even for smaller quantities. The future of digital printing, according to Mr. Amit, will be pigment printing and single pass, a technology that is already being adopted by many across the world. We are also planning to launch our pigment digital textile printing machine very soon”.