Established in the year 1985, Vee Kay Enterprises, a name synonymous with complete solutions in digital printing for various segments, including digital textile printing, launched their first-ever Made in India digital printing machine at the recently concluded GARFAB–TX exhibition in Jaipur, India. With thislaunch, the company proudly joined the “Make in India” initiative, which encourages Indian entrepreneurs to promote technology developed and manufactured locally and curb imports that hugely dent our country’s economy.

Established in the year 1985, Vee Kay Enterprises, a name synonymous with complete solutions in digital printing for various segments, including digital textile printing, launched their first-ever Made in India digital printing machine at the recently concluded GARFAB–TX exhibition in Jaipur, India. With thislaunch, the company proudly joined the “Make in India” initiative, which encourages Indian entrepreneurs to promote technology developed and manufactured locally and curb imports that hugely dent our country’s economy.

Speaking to our editor, Mr. Amit Wadhwa, Vee Kay Enterprises,we have launched the reactive printing machine and were elated with the response received for their machine,which matches globalstandardsin terms of quality and performance.

He furtherwent on to add that their entry-level machine, launched in 4- and 8-head versions, is priced quite competitivelyin comparison to Chinese brandswith similar specifications. The price advantage not just comes from being made in India, but also from the expertise and capabilitiesthat Vee Kay Enterprises has built through more than 4 decades of understanding the market needs.

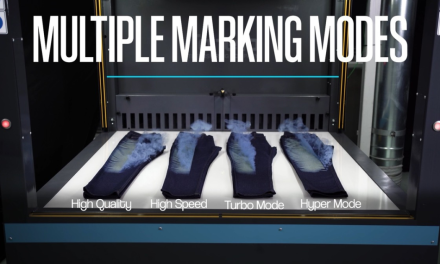

This machine is equipped with a RICOH Gen6 head, which remains the popular choice for major brands for being a highly reliable, stable, and performance orientated printhead that is also priced competitively. In terms ofspeed, the machine exceeds customer expectations by matching every feature that one might find in a 4- or 8-head machine. The production speed for a 4-head machine is 65sqm/h, while an 8-head version is 130sqm/h.

On being asked about the future of pigment inks, Mr. Amit felt that with stricter norms on environmental concerns and water conservation, pigment printing will steadily gain momentum as global demand for sustainable garments is already on the rise. The advantage of pigment printing is that it considerably reduces water usage while eliminating pre- and post-treatment processes. Also, besides garments, pigment printing can open up newer markets such as bags, jute, and footwear, a market that Vee Kay Enterprises would also like to tap in the future. Regarding the cost of the machine, Mr. Amit revealed that while the 4-head machine is priced at 40 lakhs, the 8-head version will be priced a bit higher at around 50 lakhs. In the future, though, as the volume builds up with demand, the prices might significantly reduce, making it even more affordable. Cost-wise, also, our machine offers the advantage that customers can save around 20 to 25 percent on freight and customs duty. In addition, there are inherent advantages to buying this machine, as after-sales service support and availability of spares with quick response will greatly reduce the downtime and boost production.

On being asked about the future of pigment inks, Mr. Amit felt that with stricter norms on environmental concerns and water conservation, pigment printing will steadily gain momentum as global demand for sustainable garments is already on the rise. The advantage of pigment printing is that it considerably reduces water usage while eliminating pre- and post-treatment processes. Also, besides garments, pigment printing can open up newer markets such as bags, jute, and footwear, a market that Vee Kay Enterprises would also like to tap in the future. Regarding the cost of the machine, Mr. Amit revealed that while the 4-head machine is priced at 40 lakhs, the 8-head version will be priced a bit higher at around 50 lakhs. In the future, though, as the volume builds up with demand, the prices might significantly reduce, making it even more affordable. Cost-wise, also, our machine offers the advantage that customers can save around 20 to 25 percent on freight and customs duty. In addition, there are inherent advantages to buying this machine, as after-sales service support and availability of spares with quick response will greatly reduce the downtime and boost production.

He further added, “China, where online business is thriving, and in the future, a similar trend in India will only help promote the growth of textile digital printing, which is preferred in this era of fast fashion, quicker delivery, and better production planning, even for smaller quantities. The future of digital printing, according to Mr. Amit, will be pigment printing and single pass, a technology that is already being adopted by many across the world. We are also planning to launch our pigment digital textile printing machine very soon”.